Numerical control forming method for automatically fed-in forge piece

An automatic technology for forgings, applied in the field of CNC forming of automatically fed forgings, can solve the problems of high labor intensity, large machining allowance, and low productivity, and achieve the effects of high degree of automation, small machining allowance, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

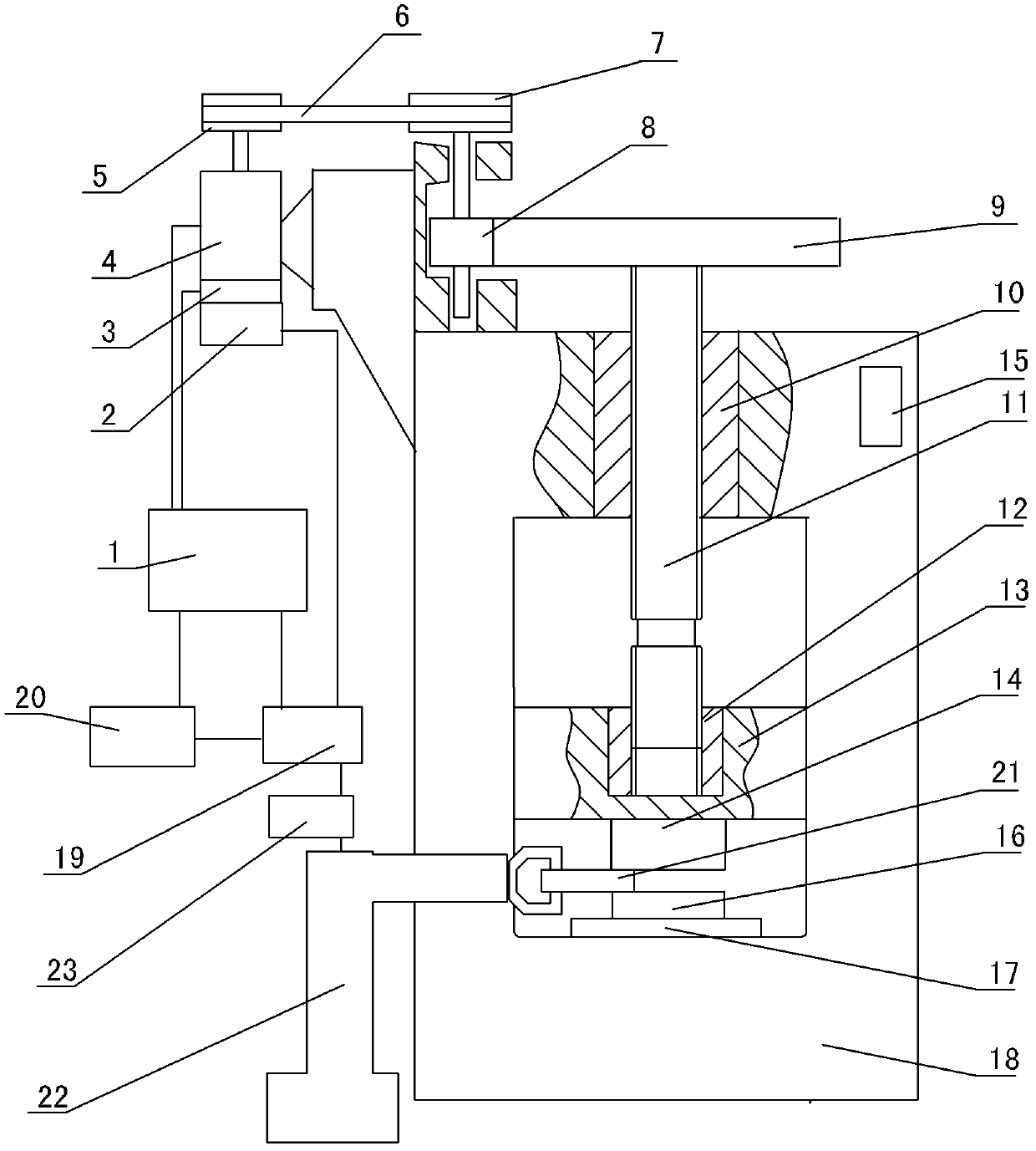

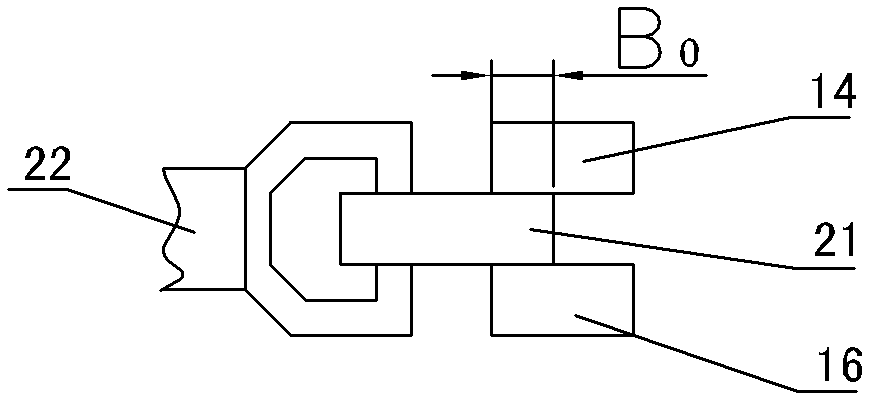

[0020] Below in conjunction with accompanying drawing, the present invention is further described: screw press comprises motor 4, control part, manipulator 22, controller 23, transmission mechanism and the working mechanism that is installed on the fuselage 18, wherein motor 4 adopts switched reluctance motor, The output end of the control part is connected to the input end of the controller 23, and the output end of the controller 23 is connected to the input end of the robot hand 22. The robot hand 22 adopts a four-degree-of-freedom universal robot hand with one clamping, one rotation and two-dimensional movement. Movement refers to the movement in the vertical direction and the movement in the feeding direction. One clamping means that the robot hand 22 clamps the workpiece 21, and one rotation means that after the robot hand 22 clamps the workpiece 21, it turns to the position of the mold. Including upper mold 14 and lower mold 16.

[0021] The control components include a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com