Preparation method of alkali aluminosilicate glass used for protective cover plates for display parts

A technology of silicate glass and protective cover plate, which is applied in the preparation of alkali aluminosilicate glass and the field of alkali aluminosilicate glass, can solve the problems of easy aging, decrease in finish, increase light scattering and other problems, and achieve high surface The effect of hardness, scratch resistance improvement, glass mechanical properties improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

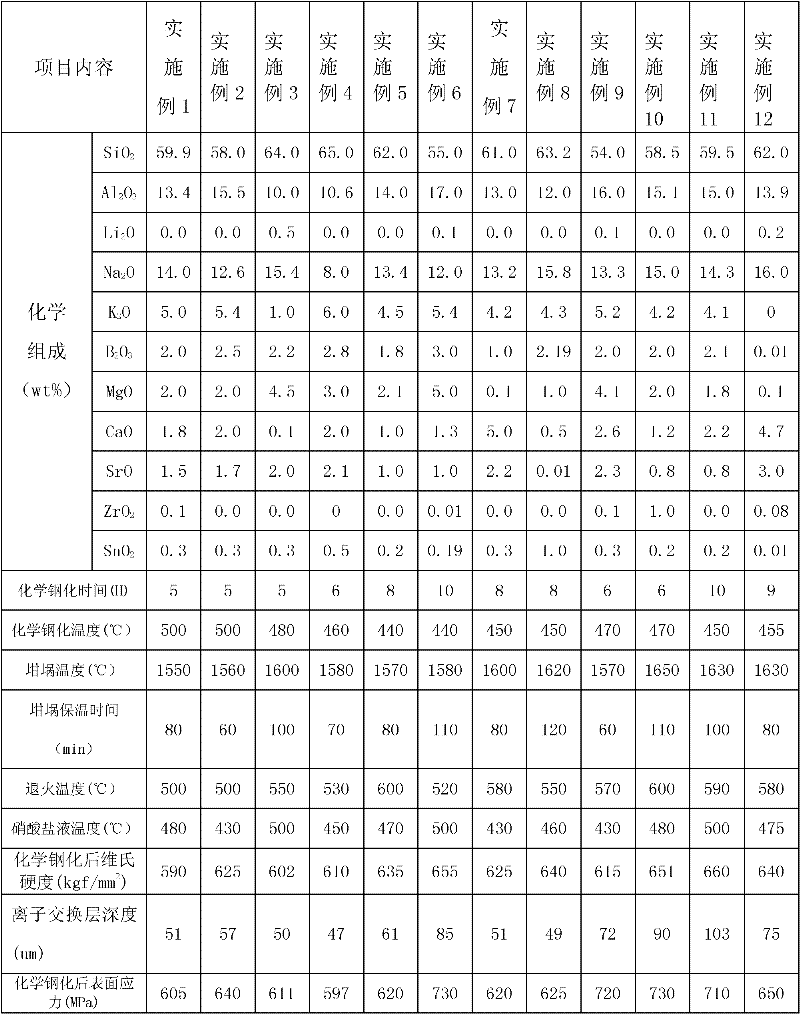

[0024] The following examples further illustrate the invention, but the data are for the purpose of illustration and illustration and are not intended to limit the invention in any way.

[0025] Table 1 is some examples of the present invention, and example requires by composition:

[0026] 1) Batching is carried out according to the mass percentage, and the percentage content of each material is 100%, and the weight is 1000g;

[0027]2) Mix the above raw materials thoroughly and put them in a platinum-rhodium alloy crucible, then put them into a container made of refractory materials, use silicon-molybdenum rods to raise the temperature in the container to 1550-1650°C, and ensure that it does not exceed 1650°C. After reacting for about 5-10 hours, lower the temperature in the container to 1580-1600°C and keep it warm for about 60-120 minutes, making sure not to exceed 120 minutes;

[0028] 3) After the heat preservation is over, quickly pour the glass liquid in the crucible ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap