Environment-friendly polyurethane composite material for foam toys and preparation method thereof

A polyurethane composite material, an environmentally friendly technology, applied in the field of polyurethane, to achieve the effect of good elasticity, excellent physical and mechanical properties, and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

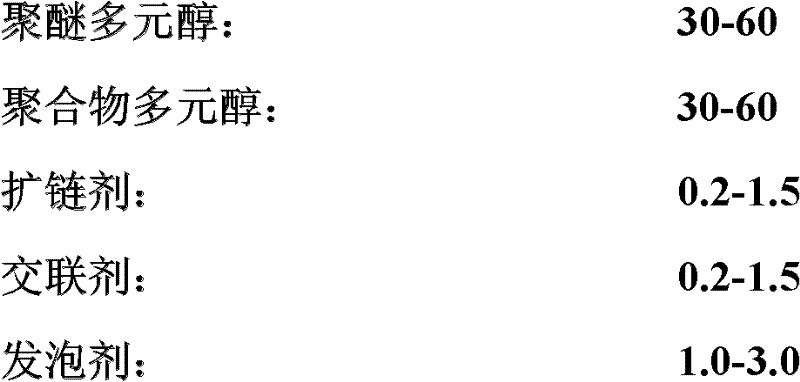

[0031] A component is:

[0032]

[0033] Group B is divided into:

[0034]

[0035] Component A: Put the weighed FA-703 and POP3630 into the reaction kettle and stir, then add the weighed DEOA, DEG, L-3415, MP601, MP602, H 2 O. After stirring and mixing at room temperature for 1 hour, take a sample for inspection, meet the process parameters, and produce satisfactory foam, that is, the qualified product of component A is obtained.

[0036] Component B: Add EP3600 and Yukol 8331 to the reaction kettle at room temperature, stir and heat up to 90°C-100°C, dehydrate and degas under vacuum (-0.098MPa) for 2-3 hours, when the temperature drops to 30°C, add pure MDI and Liquefy MDI, react for 2-3 hours when the temperature is raised to 80-85°C, and detect that the NCO% content reaches the set value (25.3%), then add crude MDI, stir and cool down to 10-40°C.

[0037] When in use, the components A and B are mixed according to the weight ratio of A:B=100:34 and injected into the...

Embodiment 2

[0039] A component is:

[0040]

[0041] Group B is divided into:

[0042]

[0043]

[0044] Component A: Put the weighed EP3600Y and POP40 into the reaction kettle and stir, then add the weighed DEOA, DEG, L-3415, EF600, EF700, H 2 O. After stirring and mixing at room temperature for 1 hour, take it out for inspection, meet the process parameters, and produce satisfactory foam, that is, the qualified product of component A.

[0045] Component B: Add FA703 and Yukol 8331 into the reaction kettle at room temperature, stir and heat up to 90°C-100°C, dehydrate and degas under vacuum for 2-3 hours, when the temperature drops to 30°C, add pure MDI and liquefied MDI, and heat up to React at 80-85°C for 2-3 hours. After the detection reaches the set NCO% content (26.1%), then add crude MDI, stir and cool down to 10-40°C.

[0046] When in use, the components A and B are mixed according to the weight ratio of A:B=100:50 and injected into the mold to obtain a polyurethane foa...

Embodiment 3

[0048] A component is:

[0049]

[0050] Group B is divided into:

[0051]

[0052] Component A: Put the EP3600Y and POP3630 based on the formula into the reaction kettle and stir, then add the weighed DEOA, DEG, L-3415, MP601, MP602, H2O respectively, stir and mix at room temperature for 1 hour, then take it out and carry out Inspection, meet the process parameters, and produce satisfactory foam, that is, the qualified product of component A.

[0053] Component B: Add FA703 and Yukol 8331 into the reaction kettle at room temperature, stir at 90°C-100°C, dehydrate and degas under vacuum for 2-3 hours, add pure MDI and MDI-50 when the temperature drops to 30°C, and heat up to 80-85°C, react for 2-3 hours, and detect that the set NCO% content is reached, then add crude MDI, stir and cool down to 10-40°C.

[0054] When in use, the components A and B are mixed according to the weight ratio of A:B=100:42 and injected into the mold to obtain a polyurethane foam toy.

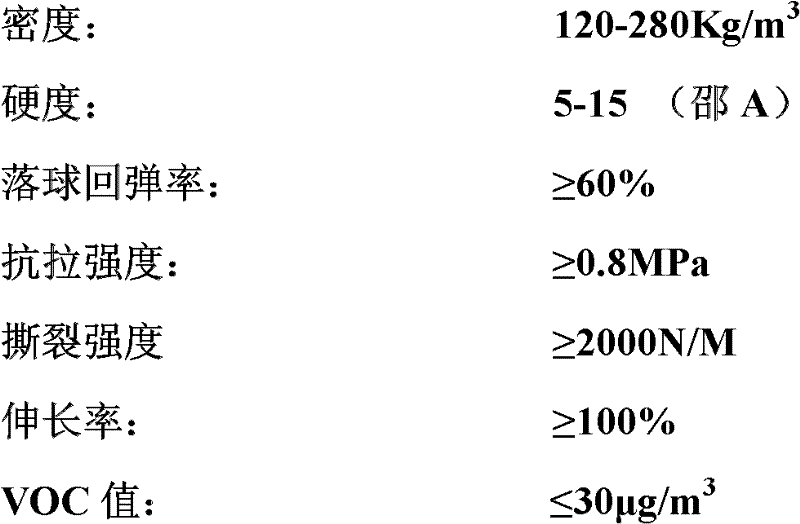

[0055...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com