Method for forming corrosion inhibiting film on steel and iron surface

A technology for steel surface and corrosion inhibition, applied in the direction of electrolytic coatings, coatings, metal material coating processes, etc., to achieve the effects of excellent corrosion inhibition effect, simple method and process, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

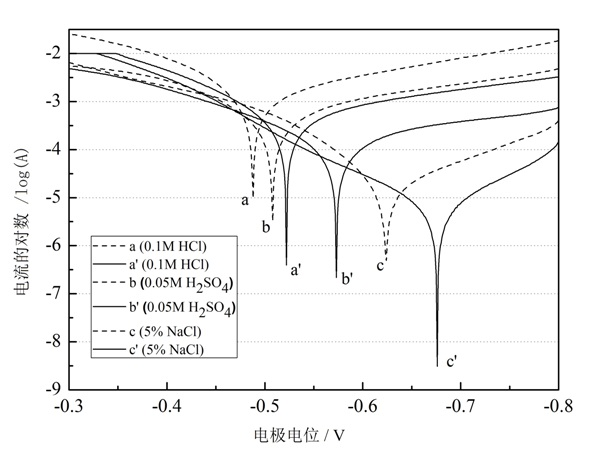

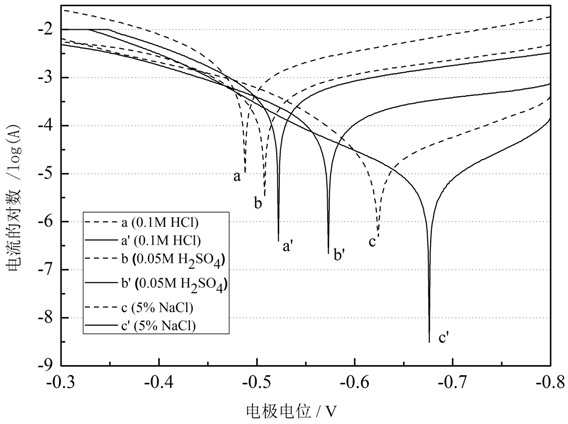

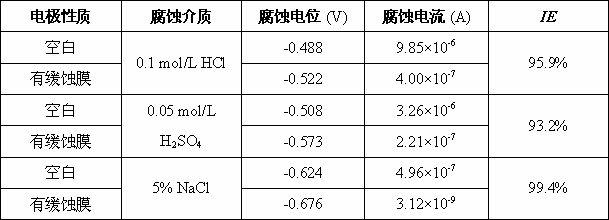

Image

Examples

Embodiment Construction

[0013] A method for forming a corrosion-inhibiting film on a steel surface, specifically comprising the following steps: 1. The steel sheet is first passed through 1 # ~ 6 # Grinding and polishing step by step with No. metallographic sandpaper, washing with deionized water, degreasing with acetone, washing with deionized water, descaling with dilute sulfuric acid, washing with deionized water, and setting aside; 2. Diazo with a concentration of 0.008 mol / L Salt solution and dilute sulfuric acid solution with a concentration of 0.015 mol / L constitute a mixed self-assembly solution; 3. Soak the steel sheet in the mixed self-assembly solution, the immersion temperature is room temperature, and the assembly time is 1.5 h; 4. Give the steel piece in the mixed solution The electrodes were polarized cathodically (potential -1.0 V) for 180 s. Below in conjunction with embodiment the present invention is described in detail:

[0014] A. Solution configuration

[0015] Diazonium p-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com