Wireless distance measuring device and wireless distance measuring method for hydraulic supports, and hydraulic support using device and method

A technology of hydraulic support and wireless distance measurement, which is applied in the direction of measuring devices, radio wave measuring systems, mining devices, etc., can solve the problems of easy damage during production and use, large accumulation of step distance errors, and high processing accuracy requirements, etc., to achieve The effect of low failure rate, improved efficiency, and improved control efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

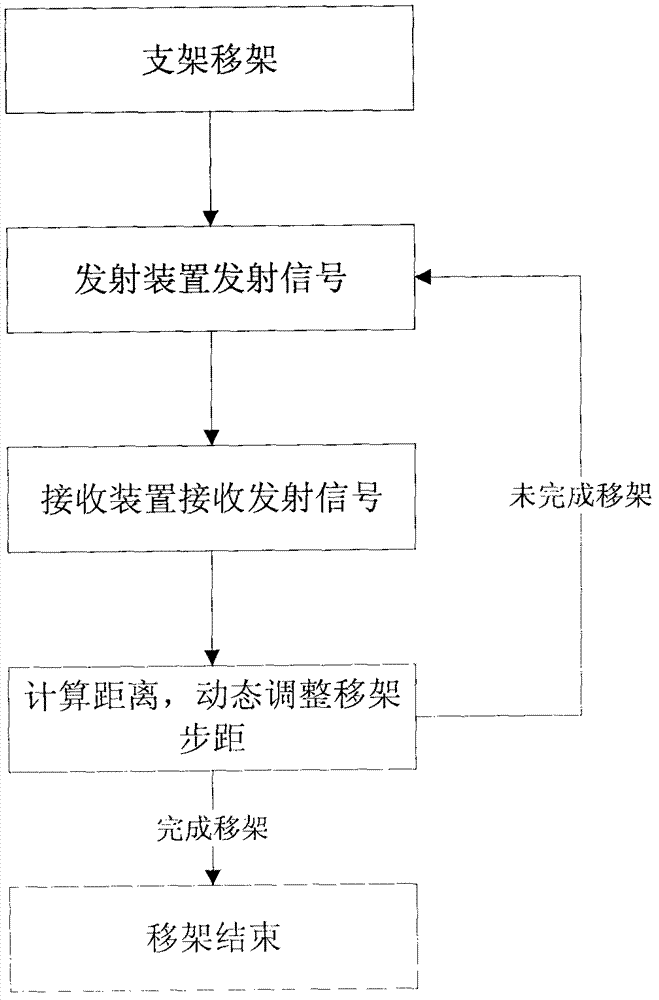

Method used

Image

Examples

Embodiment Construction

[0016] According to a preferred embodiment of the wireless distance measuring device of a hydraulic support of the present invention, it includes a hydraulic support, a support controller, a wireless transceiver and a target board, a scraper conveyor is arranged in front of the hydraulic support, and a cable is provided on the scraper conveyor. Groove, the target plate is set on the cable trough, the target plate can use any plate with a smooth surface, and the smooth surface is aligned with the wireless transceiver device through installation, when moving the frame, multiple hydraulic supports to the scraper conveyor Direction movement, when the hydraulic support moves to a suitable distance from the scraper conveyor, the hydraulic support stops moving and enters the support working state, and requires multiple hydraulic supports to be basically level or with the scraper when they stop moving and enter the working state The distance between the conveyors is basically the same....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com