Reconfigurable computer numerical control system, numerical control method thereof and reconstruction method thereof

A digital control system, computer technology, applied in the direction of digital control, electrical program control, etc., can solve the problems that cannot reflect the technical characteristics of the numerical control system, hinder the standardization process of the numerical control system, and the open concept is vague, etc., to achieve a simple logical structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

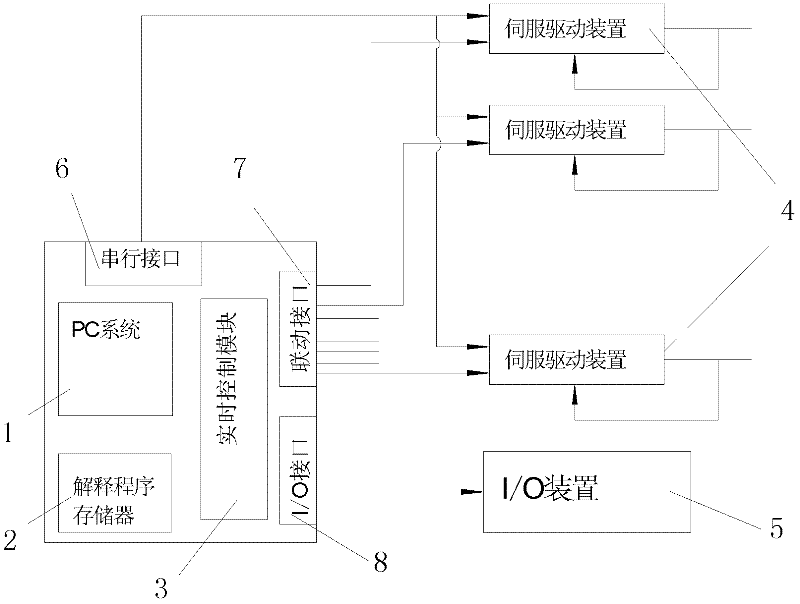

[0252] In order to ensure that the structure and layout of the machine tool can be quickly reorganized according to the changes of the processed products, the modular structure has become the basic technical feature of the reconfigurable machine tool. As a rule, the concept of modularization and its implementation is limited to machine tool manufacturers. However, in reconfigurable machine tools, the concept of modularity and its implementation must be extended to users, in other words, user-oriented is the essential feature of reconfigurability.

[0253] In reconfigurable machine tools, the so-called reconfigurability refers to the ability for users to quickly reorganize the structure, layout, and processing functions of the machine tool according to changes in the processed products.

[0254] Compared with the modularization of reconfigurable machine tools, it is generally believed that reconfigurable computer numerical control systems should also be modularized.

[0255] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com