Controllable underwater acoustic board

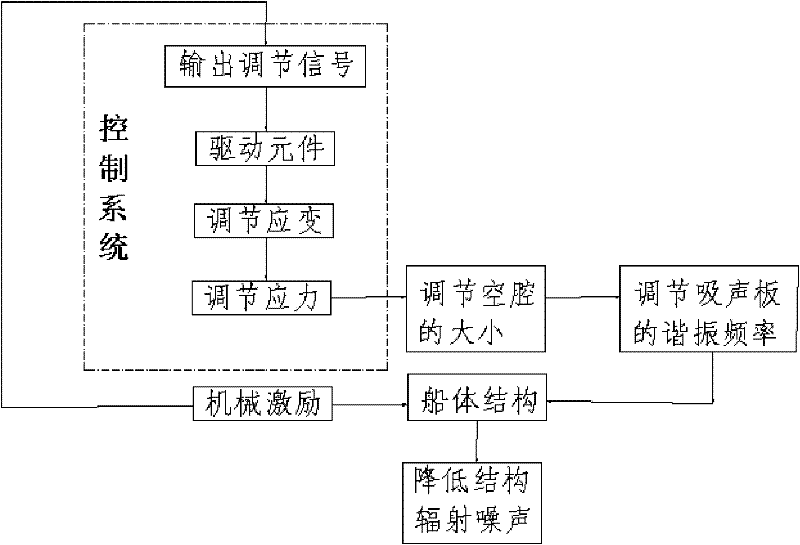

A sound-absorbing board and sound-absorbing layer technology, applied in the field of sound-absorbing materials, can solve the problems of poor low-frequency effect, narrow operating frequency bandwidth, and poor pressure-resistant performance of the sound-absorbing board, and achieve good sound absorption and sound insulation effect and low frequency effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated below in conjunction with accompanying drawing example:

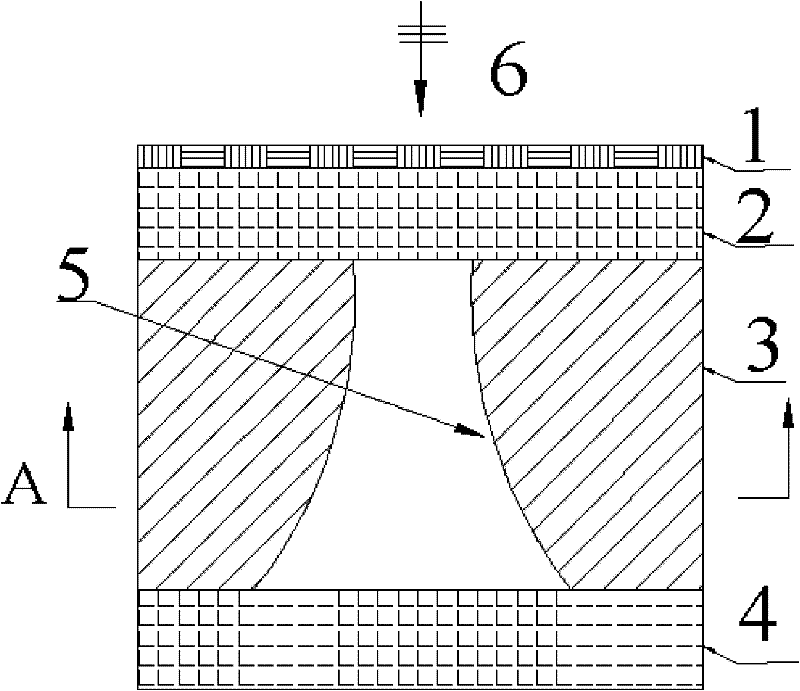

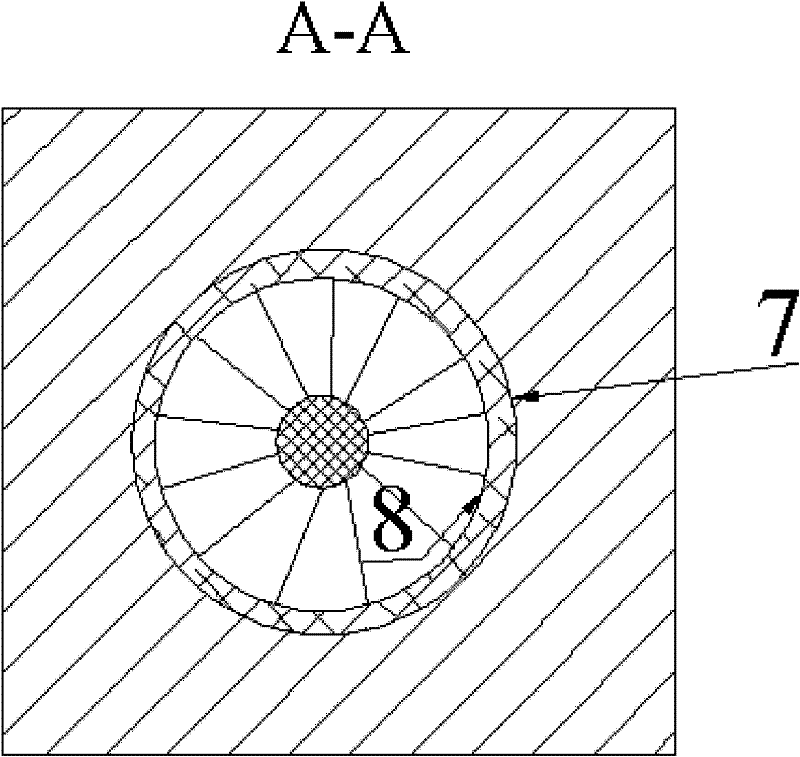

[0022] combine figure 2 and 3 , the composition of the controllable underwater sound-absorbing panel includes a sound-absorbing layer 2, a sound-insulating layer 3, and a damping layer 4. The sound-insulating layer is located between the sound-absorbing layer and the damping layer. The layers are all made of polyurethane material, a horn-shaped cavity 5 is opened in the sound-insulating layer, and a shape-memory alloy driving element 7 is buried at the mouth 8 of the horn-shaped cavity. The shape memory alloy driving element is connected with the control system. The reinforced fiber layer 1 is arranged outside the sound-absorbing layer, and the reinforced surface fiber cloth can protect the stability of the chemical and physical properties of the internal materials and structures, keep the acoustic properties unchanged for a long time, and prevent corrosion and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com