Energy feedback elevator system

An elevator system and energy feedback technology, applied in the direction of AC network voltage adjustment, reactive power compensation, elevators, etc., can solve the problems that are not conducive to product market competition and increase the cost of elevators, so as to avoid large losses, improve service life and reduce losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

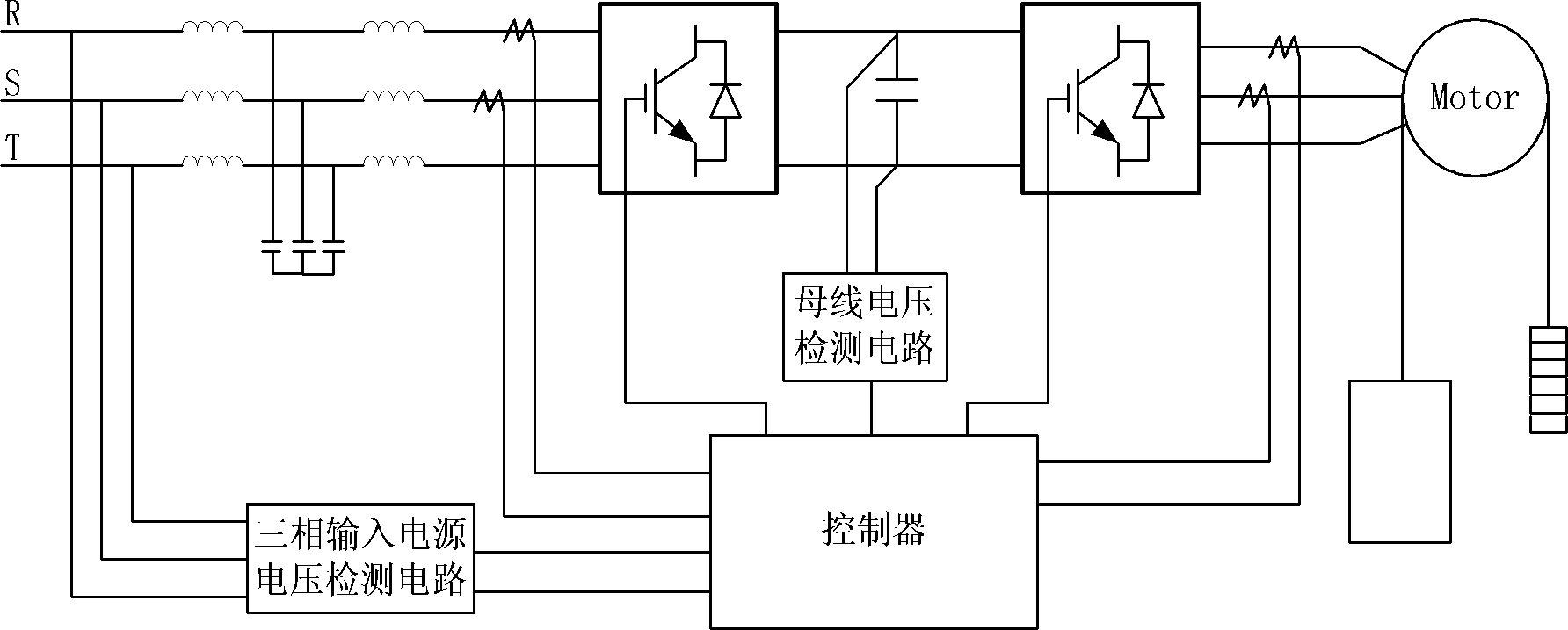

[0017] figure 1 It is a schematic diagram of the structure of the energy feedback elevator system of the present invention when it is applied to a series energy feedback elevator system. In addition to the boost filter device and the current sensor on the input side of the three-phase controllable rectifier in the existing energy feedback elevator system, the energy feedback elevator system , three-phase controllable rectifier, DC bus capacitor, three-phase inverter, current sensor on the output side of the three-phase inverter, bus voltage detection circuit and controller, also includes a three-phase input power supply voltage detection circuit, such as figure 1 As shown, the input terminal of the three-phase input power supply voltage detection circuit is connected to the three-phase power supply input terminals R, S, T, and the output terminal is connected to the controller.

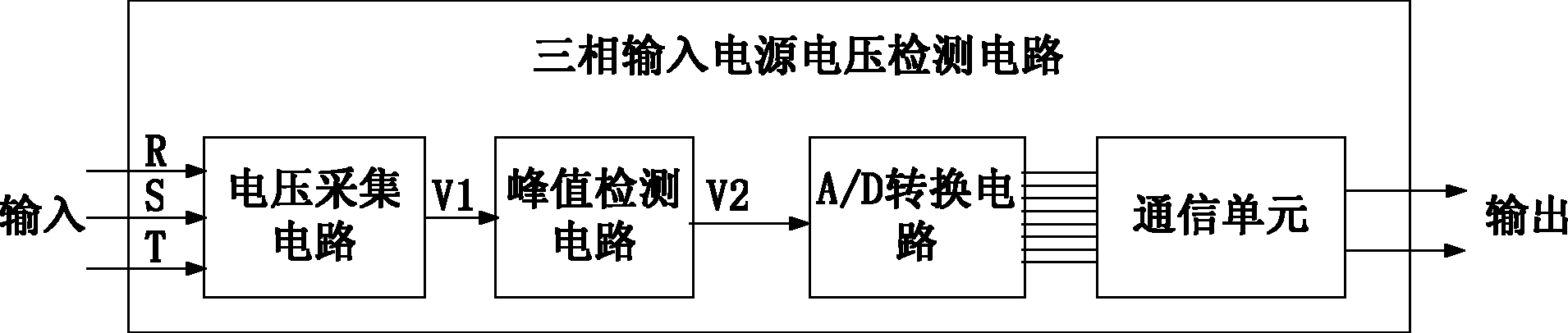

[0018] The three-phase input power supply voltage detection circuit is used to detect the maximum ...

Embodiment 2

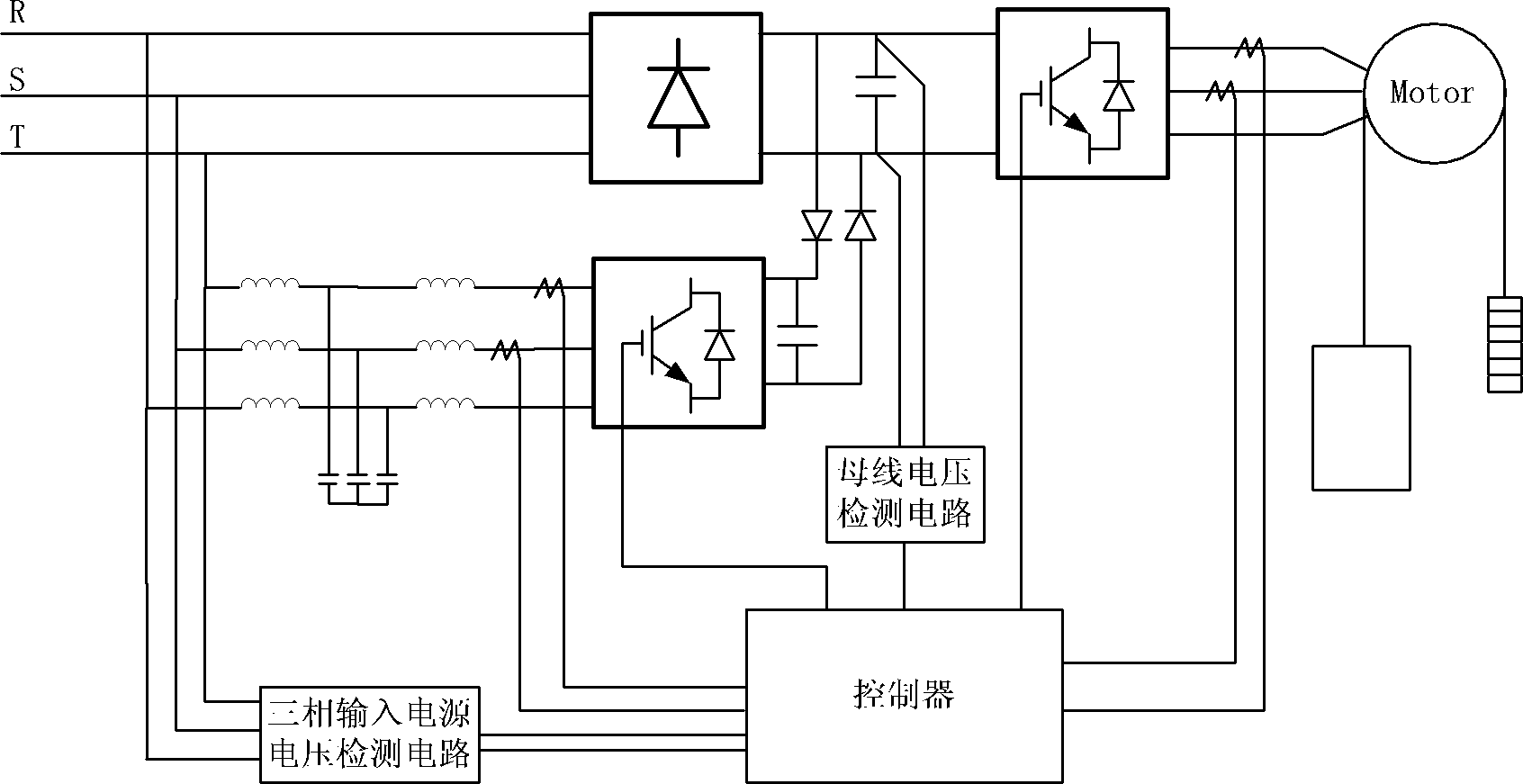

[0026] figure 2 A schematic structural diagram of another energy feedback elevator system provided by the present invention. This system is applied to a parallel energy feedback elevator system. In addition to including a three-phase uncontrollable rectifier bridge, a boost filter device, and a three-phase controllable rectifier input side In addition to the current sensor, three-phase controllable rectifier, power diode module, DC bus capacitor, three-phase inverter, current sensor on the output side of the three-phase inverter, bus voltage detection circuit and controller, it also includes three-phase input A power supply voltage detection circuit, the input terminal of the three-phase input power supply voltage detection circuit is connected to the three-phase power supply input terminals R, S, T, and the output terminal is connected to the controller.

[0027] The three-phase input power supply voltage detection circuit is used to detect the maximum value of the three-pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com