Agent for rapidly removing high sulfur coal mine underground hydrogen sulfide gas, and device thereof

A hydrogen sulfide, high sulfur technology, applied in mining equipment, mining equipment, chemical instruments and methods, etc., to achieve the effect of simple and flexible equipment, improve absorption efficiency, and promote full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

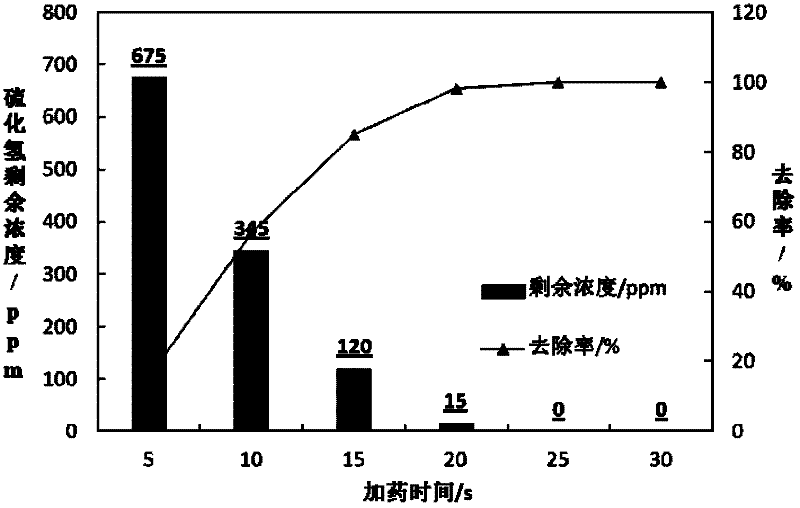

[0030] 1) Put the hydrogen sulfide sensor in the simulated roadway, set the upper limit of the sensor concentration to 800ppm, and the lower limit to 6.6ppm. The mass fractions of sodium carbonate and chloramine-T in the prepared absorption solution are 0.2% and 0.4%, respectively.

[0031] 2) Hydrogen sulfide gas is decompressed by the pressure reducing valve and adjusted by the flow meter to enter the simulated roadway, and the concentration of hydrogen sulfide in the simulated cabin is adjusted by controlling the flow and time to make it gradually increase. When the concentration exceeds the alarm limit value of 800ppm, the sensor on the sensor The automatic alarm device starts to alarm, and immediately closes the hydrogen sulfide gas cylinder to stop the air intake, and at this time, the mist misting machine automatically starts to spray. The spray volume was 1.5L / min, and the concentration of hydrogen sulfide in the simulated cabin was measured after spraying for 5s, 10s, ...

Embodiment 2

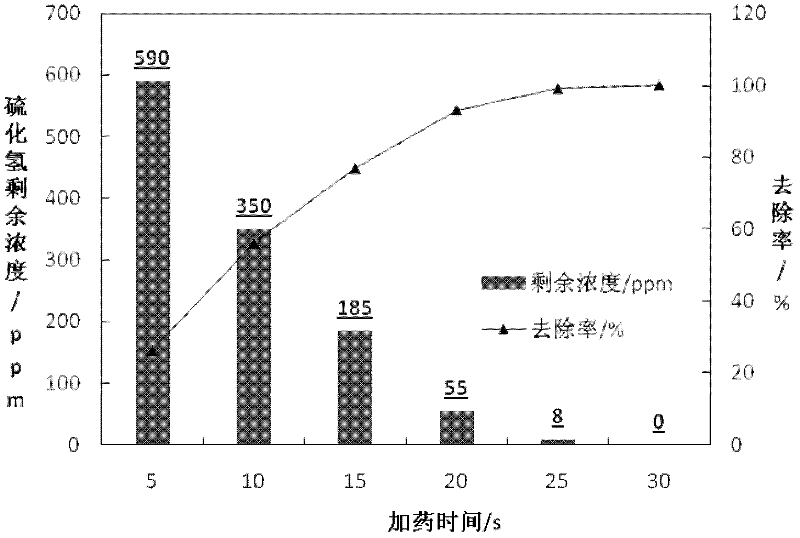

[0033] 1) Put the hydrogen sulfide sensor in the simulated roadway, set the upper limit of the sensor concentration to 800ppm, and the lower limit to 6.6ppm, and prepare the mass fractions of sodium carbonate and chloramine-T in the absorption solution to 0.3% and 0.3%, respectively.

[0034] 2) Hydrogen sulfide gas is decompressed by the pressure reducing valve and adjusted by the flow meter to enter the simulated roadway, and the concentration of hydrogen sulfide in the simulated cabin is adjusted by controlling the flow and time to make it gradually increase. When the concentration exceeds the alarm limit value of 800ppm, the sensor on the sensor The automatic alarm device starts to alarm, immediately close the hydrogen sulfide gas cylinder to stop the air intake, and turn on the fog machine for spraying. The spray volume was 1.5L / min, and the concentration of hydrogen sulfide in the simulated cabin was measured after spraying for 5s, 10s, 15s, 20s, 25s, and 30s respectively...

Embodiment 3

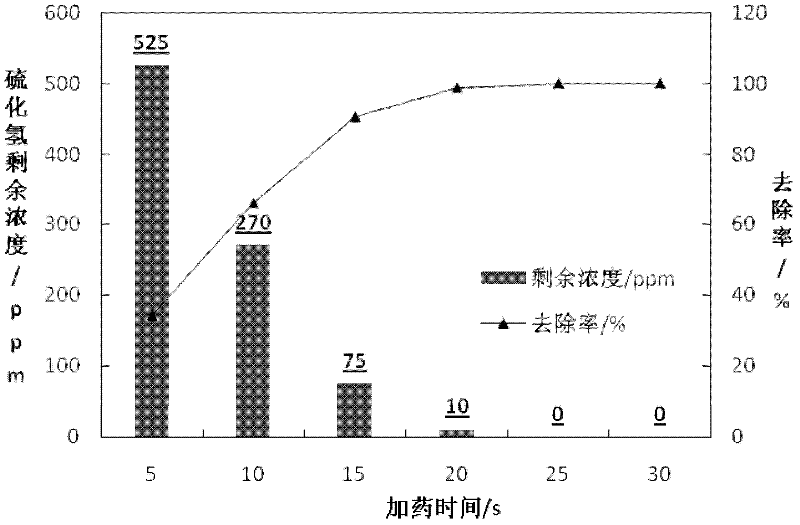

[0036] 1) Put the hydrogen sulfide sensor in the simulated roadway, set the upper limit of the sensor concentration to 800ppm, and the lower limit to 6.6ppm. The mass fractions of sodium carbonate and chloramine-T in the prepared absorption solution are 0.3% and 0.5%, respectively.

[0037] 2) Hydrogen sulfide gas is decompressed by the pressure reducing valve and adjusted by the flow meter to enter the simulated roadway, and the concentration of hydrogen sulfide in the simulated cabin is adjusted by controlling the flow and time to make it gradually increase. When the concentration exceeds the alarm limit value of 800ppm, the sensor on the sensor The automatic alarm device starts to alarm, immediately close the hydrogen sulfide gas cylinder to stop the air intake, and turn on the fog machine for spraying. The spray volume was 1.5L / min, and the concentration of hydrogen sulfide in the simulated cabin was measured after spraying for 5s, 10s, 15s, 20s, 25s, and 30s respectively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com