Double compensation method and device for moving tilt of numerical control floor type boring-milling machine ram

A compensation method, floor boring technology, which is applied in the field of CNC machine tools, can solve problems such as low compensation accuracy, excessive deformation of the spindle box, and uncompensated ram, and achieve high compensation accuracy, good effect, and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

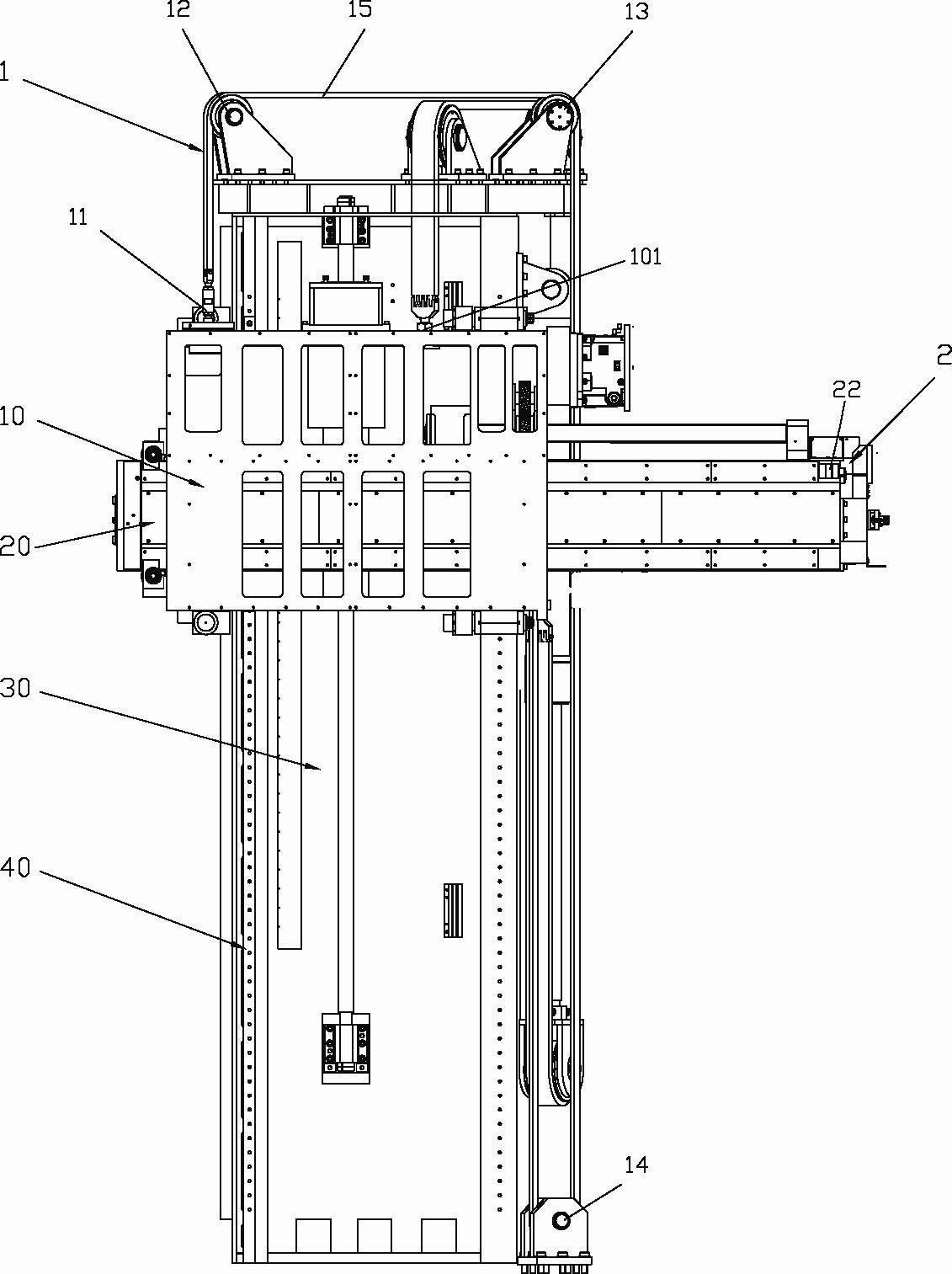

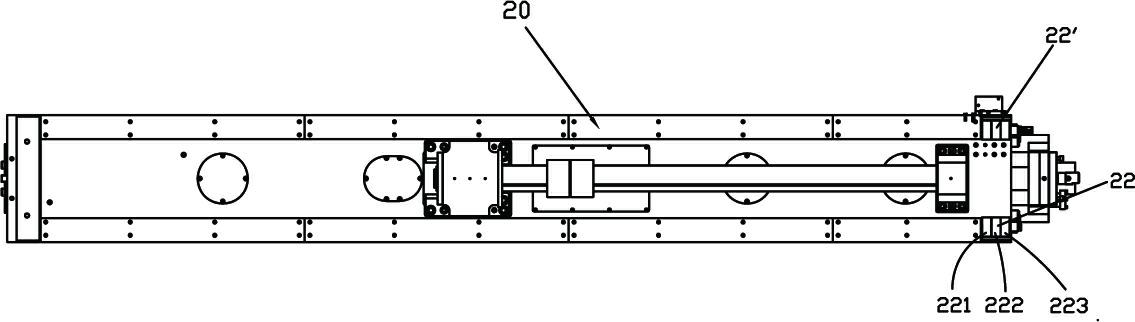

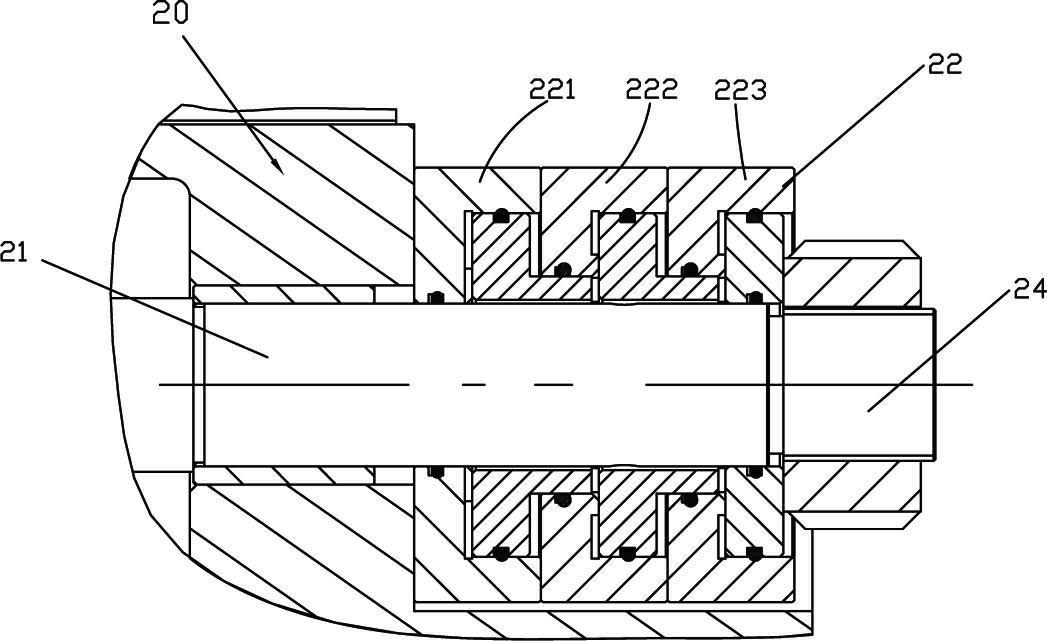

[0046] see Figure 1 to Figure 5 , a dual compensation device for the movement and inclination of the ram of a CNC floor boring and milling machine according to the present invention includes a headstock 10 inclination compensation mechanism 1 and a ram 20 deformation compensation mechanism 2 .

[0047] The headstock tilt compensation mechanism 1 includes a compensation hydraulic cylinder 11, which is arranged on one side of the upper end surface of the headstock 10 running on the guide rail 40 of the column 30, that is, on the other side relative to the headstock lifting point 101, the lifting point 101 is set At the position of the center of gravity of the main shaft box in the state where the main shaft does not extend; the first and second fixed pulleys 12, 13, wherein the first fixed pulley 12 is arranged on the top or upper part of the column 30 on the side of the corresponding compensation hydraulic cylinder 11 through a fixed bracket , the second fixed pulley 13 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com