Ventilated rain removal grating for train air-conditioning system

An air-conditioning system and train technology, applied in sustainable transportation, railway car body parts, railway vehicle heating/cooling, etc., can solve the problem that rainwater cannot be completely prevented from entering, and achieve simple structure, improved exhaust capacity, and increased contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

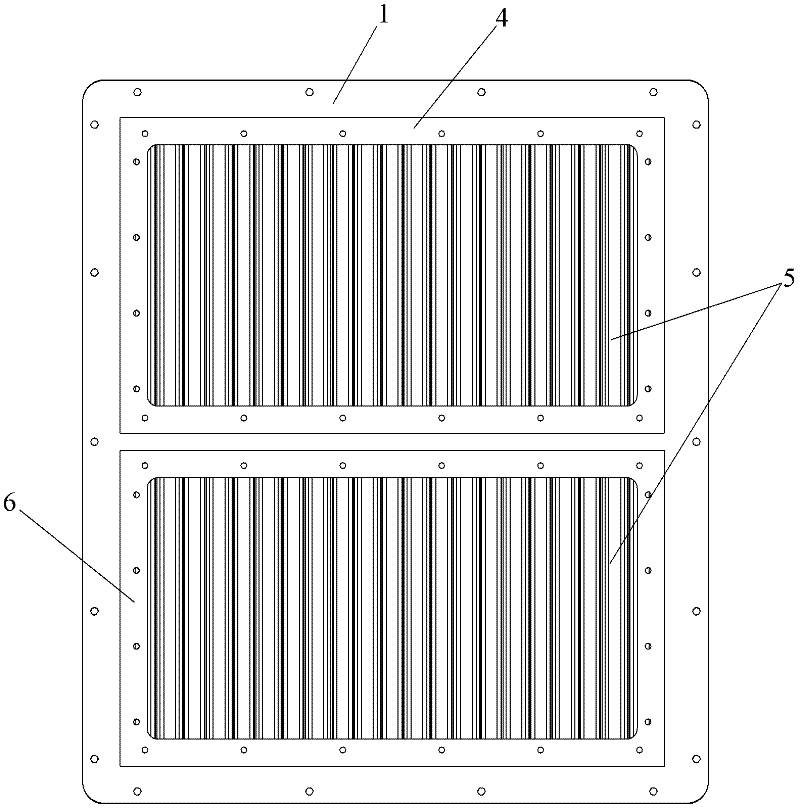

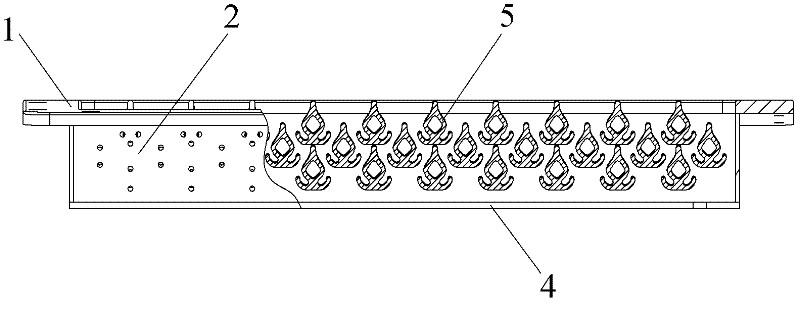

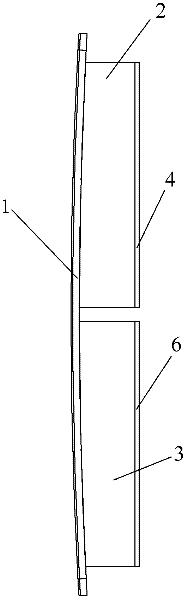

[0039] like figure 1 , figure 2 , image 3 , Figure 4 and Image 6 The ventilation and rain-removing grille for a train air-conditioning system includes a grille frame installed on the outside of the train compartment, and the grille frame is provided with an air inlet channel and an air exhaust channel, and the air inlet channel is connected with the inside of the train. The air supply fan of the air conditioning unit is connected, and the exhaust channel is connected with the exhaust fan of the air conditioning unit in the train. A plurality of rain-proof and pressure-resistant components 5 are arranged in the air inlet channel and the air exhaust channel. In the present invention, by arranging a plurality of rain-proof and pressure-resistant components 5 in the air inlet passage and the air exhaust passage, it is possible to make when the fast and high-speed train is running, when the train enters the tunnel and the two cars meet, due to the external air pressure of th...

Embodiment 2

[0046] like Figure 5 As shown, the difference between this embodiment and Embodiment 1 is only that: the upper ends of the multiple rain-proof and pressure-resistant components 5 in the air inlet passage are all inclined to the inside of the train; The lower ends of 5 all incline towards the train interior. The advantage of setting like this is: because this ventilating and rain-removing grille is arranged under the car window, the upper ends of a plurality of rain-proof and pressure-resisting components 5 in the air-intake channel are all inclined to the inside of the train, which can increase the contact area between the air-intake channel and the air , the air intake capacity of the air intake channel is enhanced, and the lower ends of the multiple rain-proof and pressure-resistant components 5 in the exhaust channel are all inclined to the inside of the train, which reduces the contact area between the exhaust channel and the air, and improves the discharge capacity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com