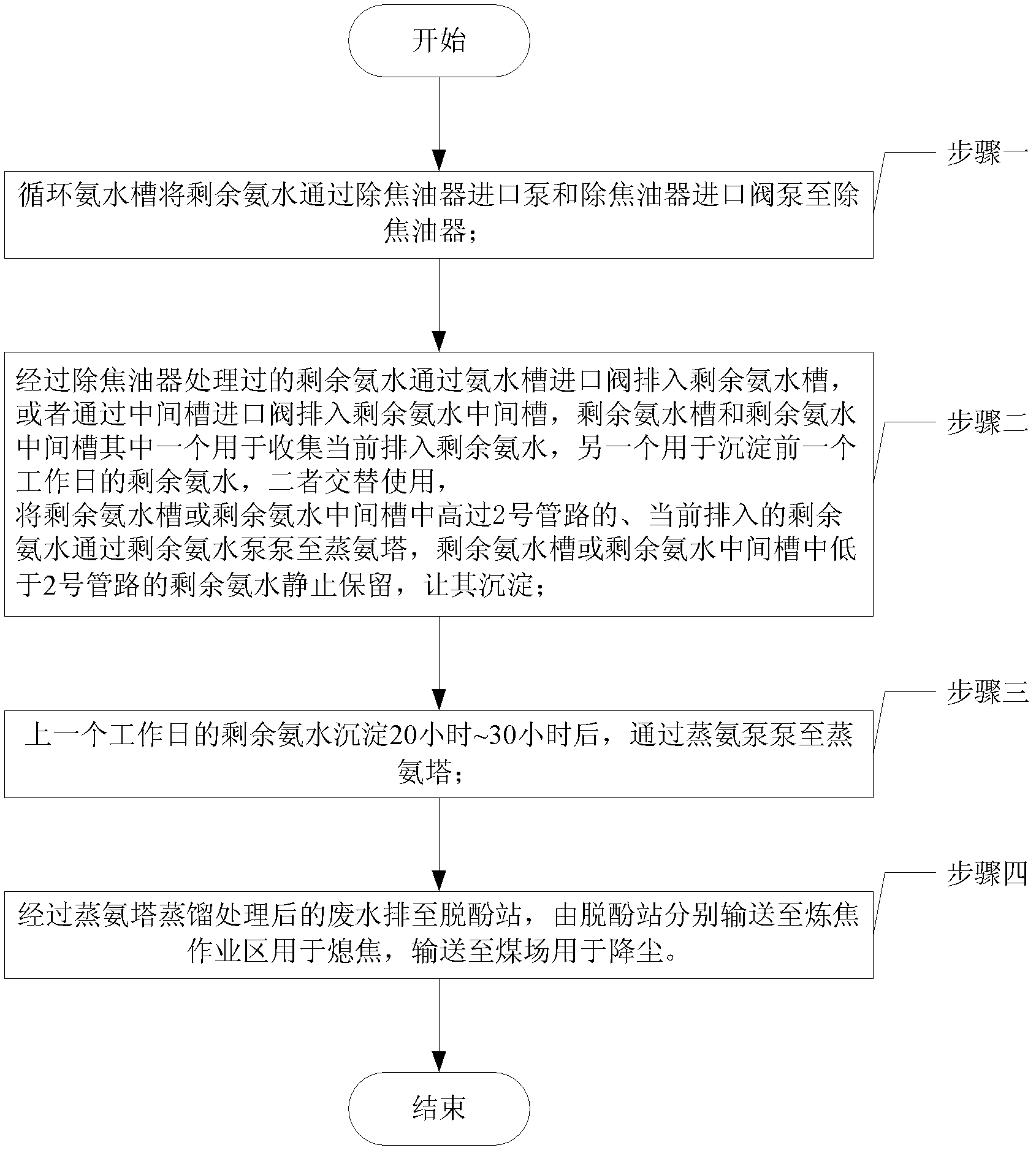

Residual ammonia water degreasing method

A technology for removing oil and residual ammonia with ammonia water, applied in the field of machinery, can solve the problems of reduced processing efficiency, high water tar content, poor tar effect, etc., and achieve the effects of reducing impact, reducing the number of tar residue cleaning, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

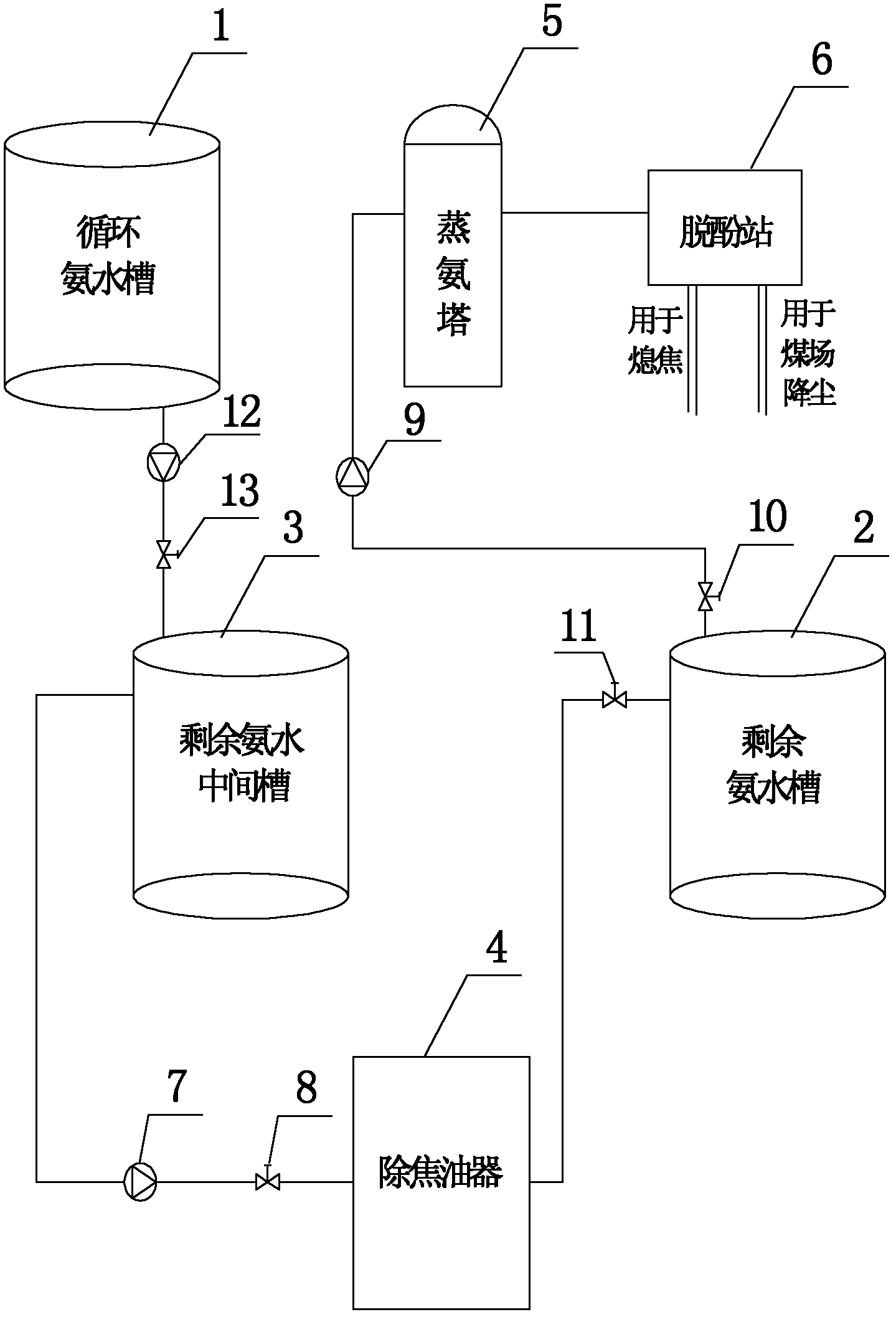

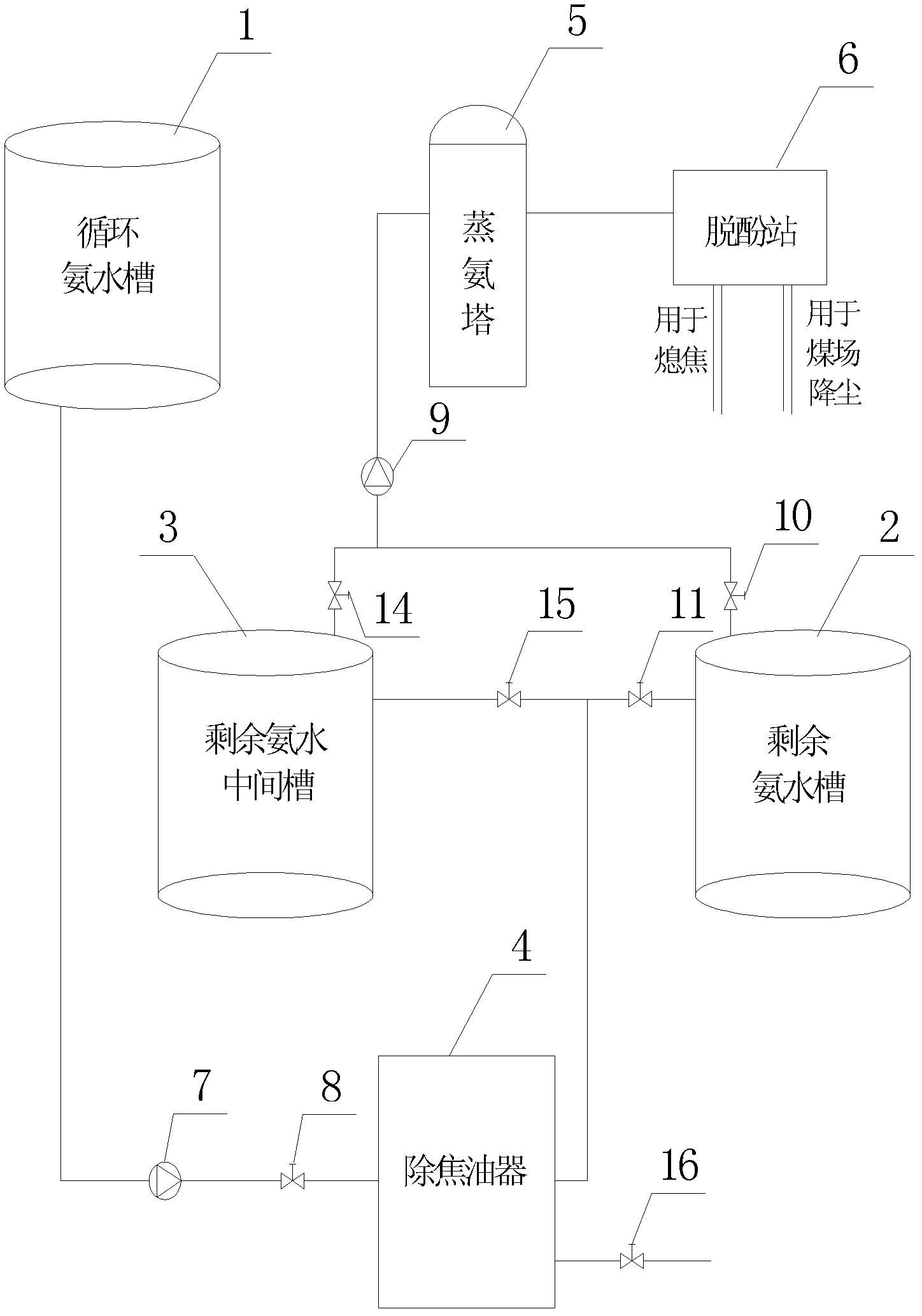

[0023] Specific implementation mode one: the following combination figure 1 and image 3 Describe this embodiment mode, a kind of remaining ammonia water degreasing method described in this embodiment, the device that this method uses comprises circulating ammonia water tank 1, remaining ammonia water tank 2, remaining ammonia water intermediate tank 3, tar remover 4, ammonia distillation tower 5, Dephenol removal station 6, tar remover inlet pump 7, tar remover inlet valve 8, residual ammonia water pump 9, ammonia water tank outlet valve 10, ammonia water tank inlet valve 11, middle tank outlet valve 14 and middle tank inlet valve 15,

[0024] The circulating ammonia water tank 1 and the inlet of the tar remover 4 are connected through the No. 1 pipeline, and the inlet pump 7 of the tar remover and the inlet valve 8 of the tar remover are arranged on the No. 1 pipeline, and the outlet of the tar remover 4 is connected with the residual ammonia The water tanks 2 are communic...

specific Embodiment approach 2

[0073] Specific implementation mode 2: This implementation mode further explains the implementation mode 1. The No. 1 pipeline is a DN80 pipeline with a length of 8 m to 15 m.

specific Embodiment approach 3

[0074] Embodiment 3: This embodiment further explains Embodiment 2. The inlet valve 8 of the tar remover is a DN80 valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com