Annular shield machine and tunnel construction method

A shield machine, annular technology, applied in the direction of tunnel, tunnel lining, earth drilling and mining, etc., to achieve the effect of reducing the opportunity of use and easy stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

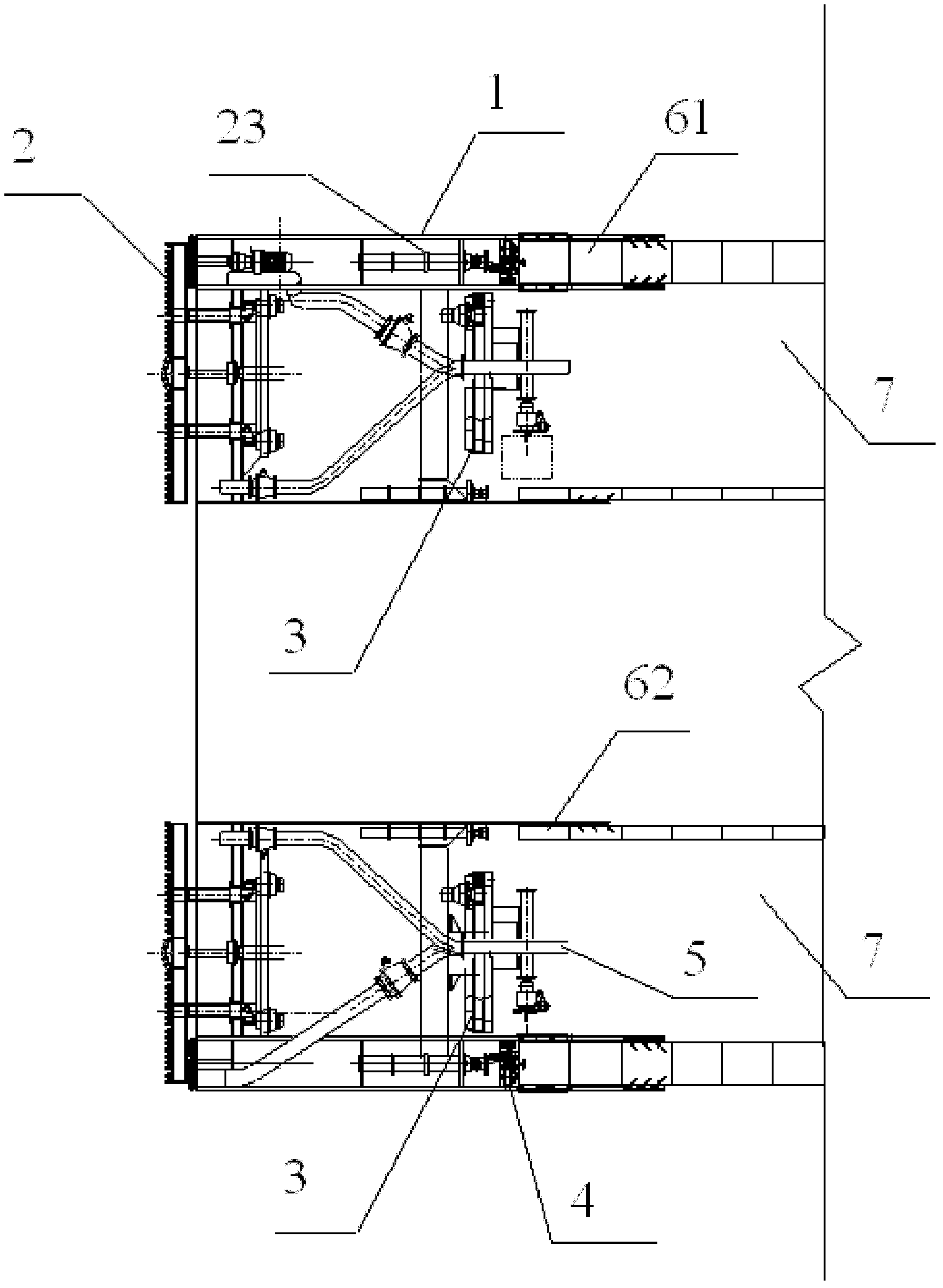

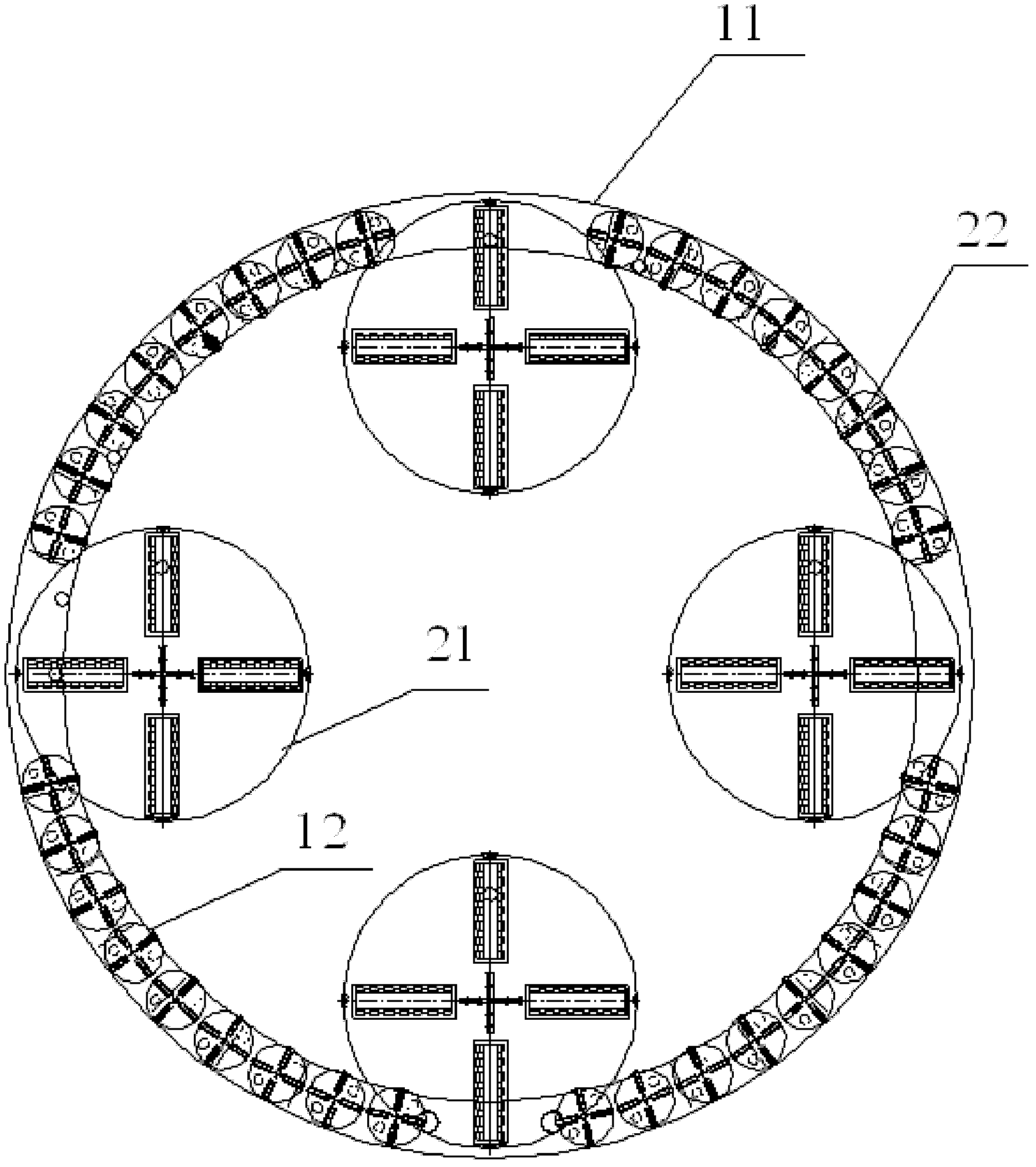

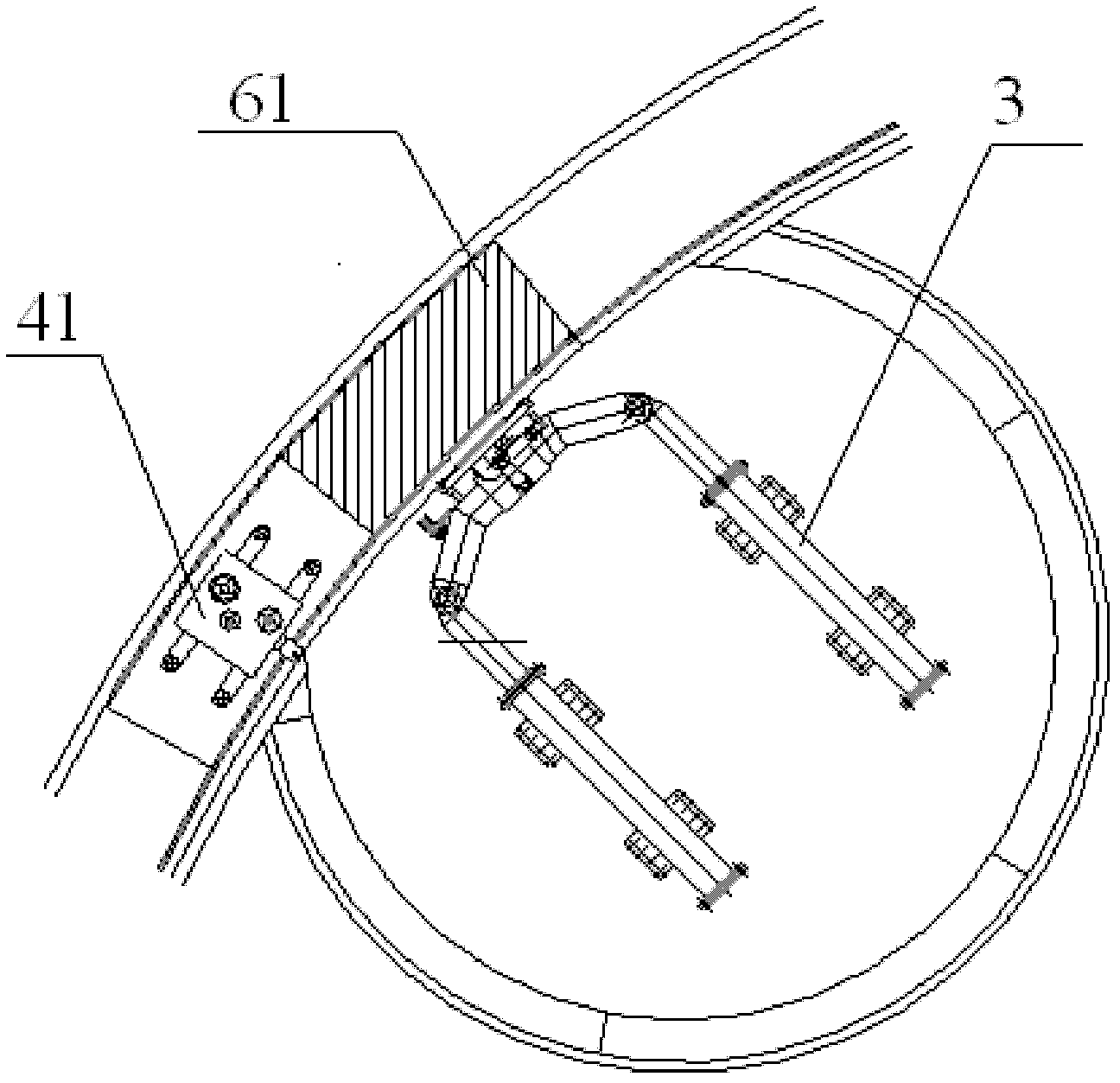

[0029] The annular shield machine of the present invention has an annular shield shell 1 completely different from the conventional circular full-section shield machine, which includes an outer shell 11, an inner shell 12 and a small shield shell 13, the inner shell The shell 12, the small shield shell 13 and the outer shell 11 form an annular cavity. The surrounding formation soil is supported by the outer shell 11, and the assembly of the main pipe piece 61 and the temporary pipe piece 62 is completed under the protection of the outer shell 11;

[0030] The main cutting cutter head 21 is set in the small shield shell 13. Considering the needs of the equipment layout inside the entire shield, the excavation system generally selects muddy water pipelines to discharge the cut soil. The main cutting cutter head 21 must be connected with the inner casing 12 of the annular shield, so that the main pipe piece 61 in the passage can be moved to the position required for the assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com