Air valve nozzle core manufacture method

A manufacturing method and valve technology, which are applied in the manufacturing field, can solve the problems of low processing efficiency, high cost of copper materials, and troublesome processing, and achieve the effects of improved production efficiency, good processing performance and convenient processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

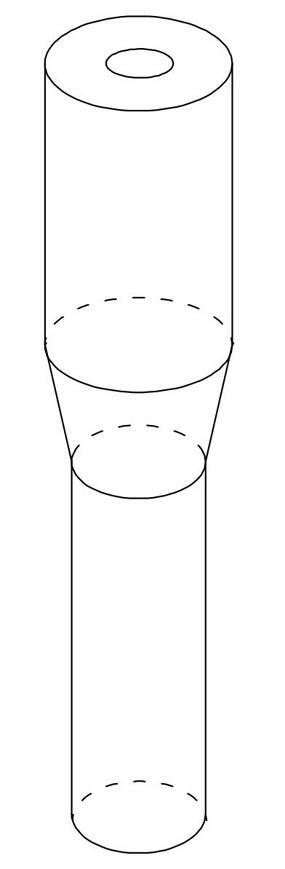

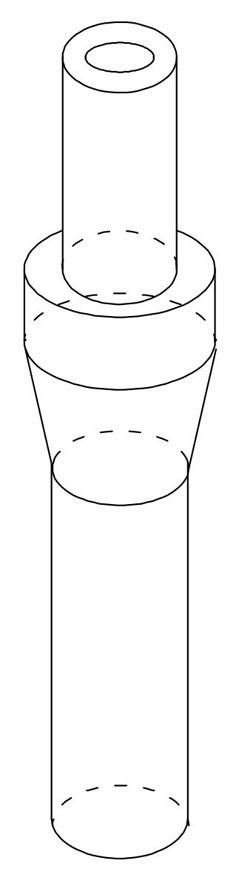

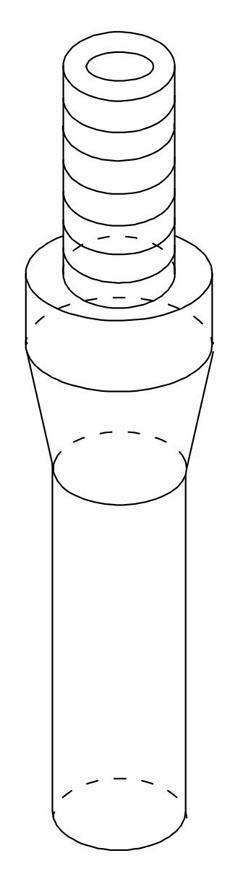

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following specific embodiments.

[0018] A method for manufacturing a valve core is made of aluminum alloy material, which includes the following steps:

[0019] (1) Blanking;

[0020] (2) Stamping and forming with a cold heading machine;

[0021] (3) Cutting with automatic lathe;

[0022] (4) Processing external threads;

[0023] (5) Machining internal threads;

[0024] (6) Product surface oxidation treatment.

[0025] The processing of the external thread in step (4) refers to processing with a thread rolling machine.

[0026] Said step (1) blanking refers to changing the original disc-shaped aluminum rod into a small section of a small section of aluminum column, which facilitates the stamping and forming of the cold forging machine in step (2).

[0027] The described step (2) is stamped and formed with a cold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com