Method for preparing composite photocatalyst CdS/ZIF-8 by one-pot method and application of composite photocatalyst CdS/ZIF-8

A technology of ZIF-8 and complex light, which is applied in the direction of organic compound/hydride/coordination complex catalyst, chemical instrument and method, physical/chemical process catalyst, etc., can solve the problem of unsuitable industrial production application, complicated preparation steps, etc. problems, to achieve the effects of broad industrial application prospects, simple process, excellent hydrogen production performance and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

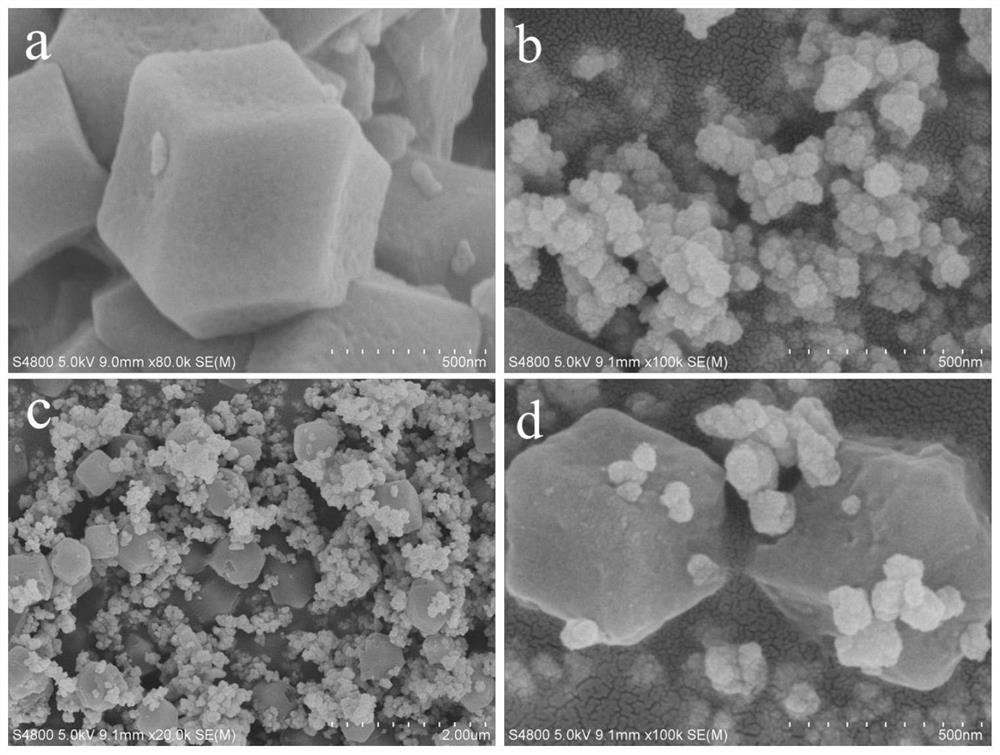

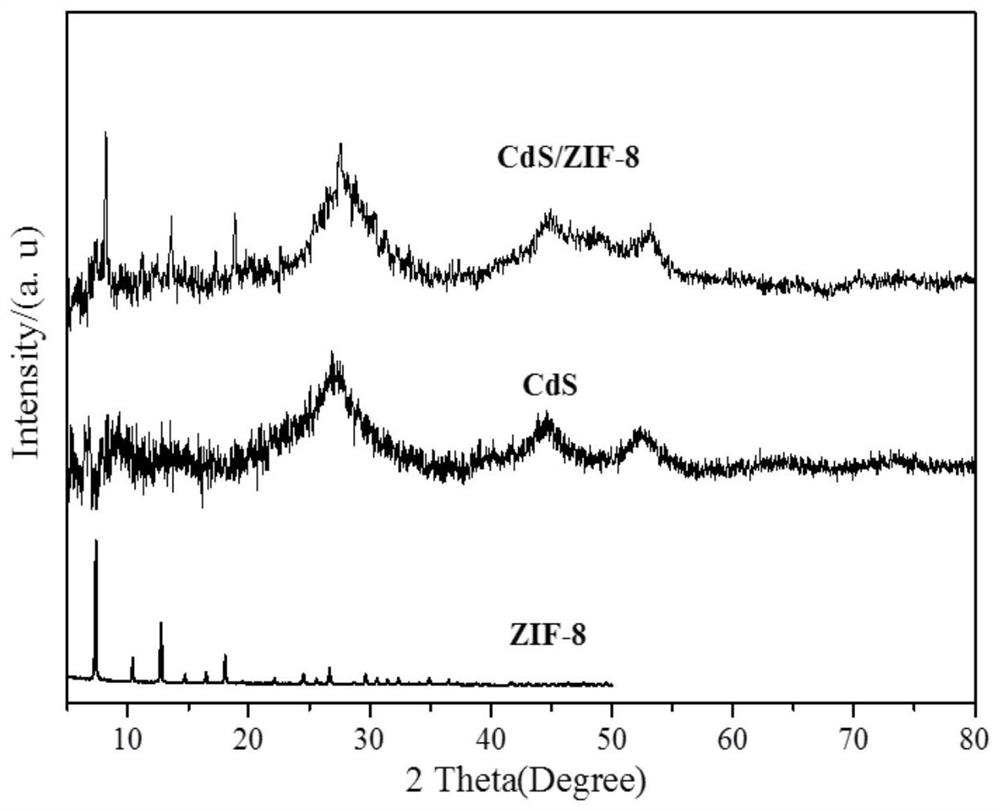

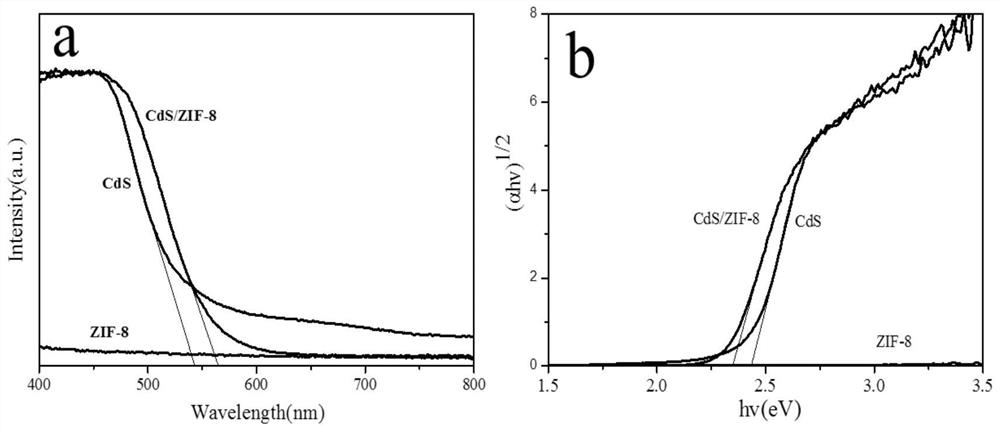

[0043] In this example, a one-pot method is used to prepare the composite photocatalyst CdS / ZIF-8, and the steps are:

[0044] (1) Add 1mmol Zn(NO 3 ) 2 ·6H 2 O and 9mmol Cd(NO 3 ) 2 4H 2O was added into 100mL of methanol together, stirred until clear and transparent, and solution A was obtained.

[0045] (2) 18mmol C 4 h 6 N 2 (2-Methylimidazole) was added into 100 mL of methanol, stirred until clear and transparent, and solution B was obtained.

[0046] (3) After mixing solutions A and B, let them stand for aging for 11 hours, and then add 27 mmol CH to the mixed solution 4 N 2 S (ammonium thiocyanate), stirred for 3h, and centrifuged to obtain a yellow reaction product.

[0047] (4) After the reaction, the reaction product was alternately washed three times with distilled water and ethanol, and dried at 50°C to obtain the supported composite photocatalyst CdS / ZIF-8.

[0048] During the one-pot preparation of CdS / ZIF-8, adding Zn ions, Cd ions and excess 2-methyl...

Embodiment 2

[0050] This embodiment is on the basis of embodiment 1, the "18mmol C in step (2) 4 h 6 N 2 (2-Methylimidazole)" was changed to "27mmol C 4 h 6 N 2 (2-Methylimidazole)".

Embodiment 3

[0052] This embodiment is on the basis of embodiment 1, the "27mmol CH in step (3) 4 N 2 S (ammonium thiocyanate)" to "36mmol CH 4 N 2 S (ammonium thiocyanate)".

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com