Preparation method of highly doped nitrogen, phosphorus and carbon nano-sheet for efficient hydrogen production

A carbon nanosheet, high-doping technology, applied in the preparation/purification of carbon, nanotechnology for materials and surface science, nanocarbon, etc., can solve the problem of lack of catalyst design, etc., to increase catalytic active sites, Ease of operation and performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Put urea and carbon black with a mass ratio of 4:1, and 0.1-1g of sodium metaphosphate, in a certain volume of deionized water, stir magnetically at 60°C for 90 minutes to form a clear solution, and dry in an oven to obtain a precursor A 1 .

[0020] (2) Precursor A 1 Transferred to a tube furnace under a protective atmosphere, treated at a high temperature of 700°C for 3 hours, and cooled naturally to room temperature to obtain the heteroatom-doped carbon material.

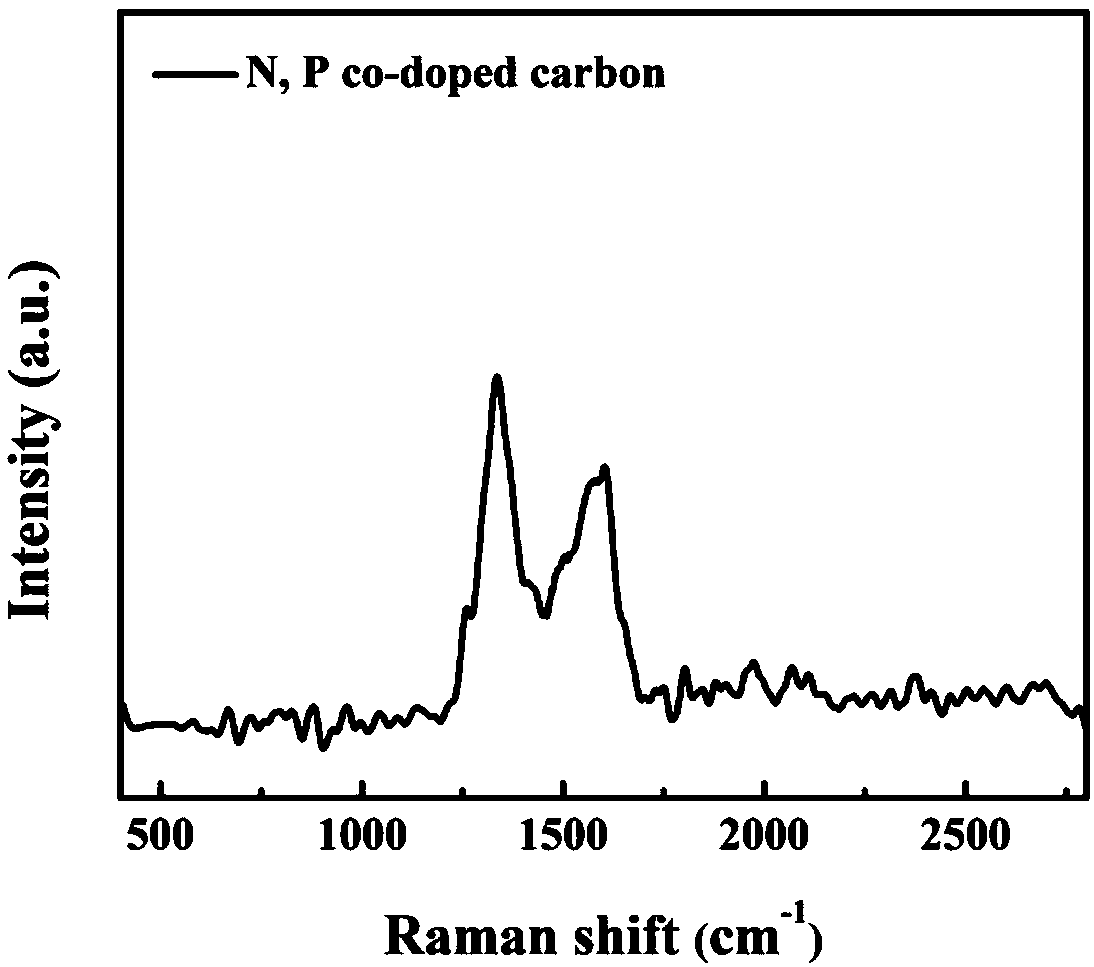

[0021] figure 1 It can be seen from the Raman spectrum of the highly doped nitrogen-phosphorus carbon material obtained in this example that the obtained material is a sheet carbon material with a graphene phase, accompanied by the existence of a large number of defect states.

Embodiment 2

[0023] (1) Put melamine and urea with a mass ratio of 2:1, and 0.5 to 2 g of sodium phosphate in a certain volume of deionized water, stir magnetically at 70°C for 90 minutes to form a clear solution, and dry in an oven to obtain precursor A 1 .

[0024] (2) Precursor A 1 Transferred to a tube furnace in a protective atmosphere, treated at a high temperature of 800°C for 3 hours, and cooled naturally to room temperature to obtain the heteroatom-doped carbon material.

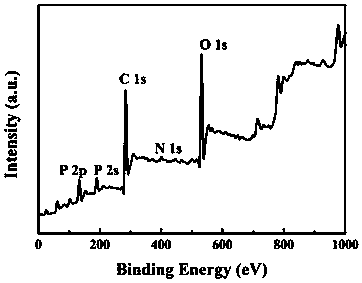

[0025] figure 2 It is the X-ray photoelectron spectrum diagram of the carbon material highly doped with nitrogen and phosphorus prepared in this example. It can be seen from the figure that the obtained material contains nitrogen and phosphorus content, and the nitrogen content is 3.91%, and the phosphorus content is 6.77%.

Embodiment 3

[0027] (1) Put melamine and carbon black at a mass ratio of 4:1, and 0.1-10ml of phytic acid in a certain volume of deionized water, stir magnetically at 70°C for 90 minutes to form a clear solution, and dry in an oven to obtain precursor A 1 .

[0028] (2) Precursor A 1 Transferred to a tube furnace in a protective atmosphere, treated at 900°C for 5 hours at a high temperature, and cooled naturally to room temperature to obtain the heteroatom-doped carbon material.

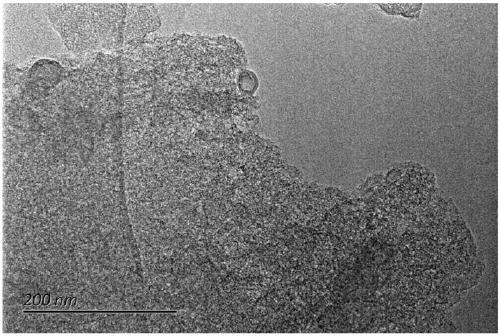

[0029] image 3 It is a transmission electron microscope image of the carbon material highly doped with nitrogen and phosphorus prepared in this example. It can be seen from the figure that the microscopic morphology of the carbon material is a lamellar structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com