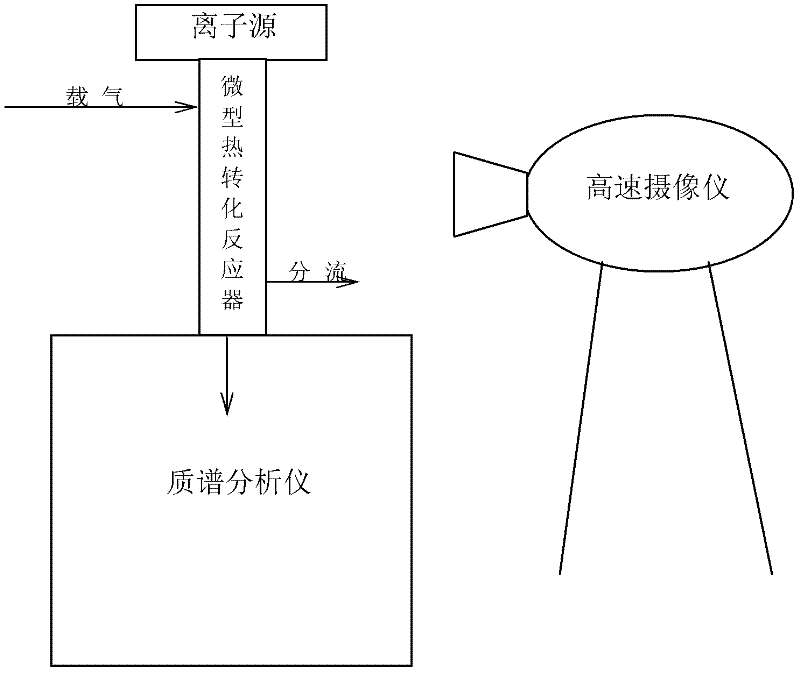

In-situ detection device and detection method for heat conversion reaction process of solid fuel

A solid fuel, in-situ detection technology, applied in the direction of measuring devices, material analysis, material analysis by electromagnetic means, etc., can solve the problem that the rapid pyrolysis process is difficult to effectively simulate, lacks real-time detection methods for solid fuel, and cannot continuously analyze process products And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

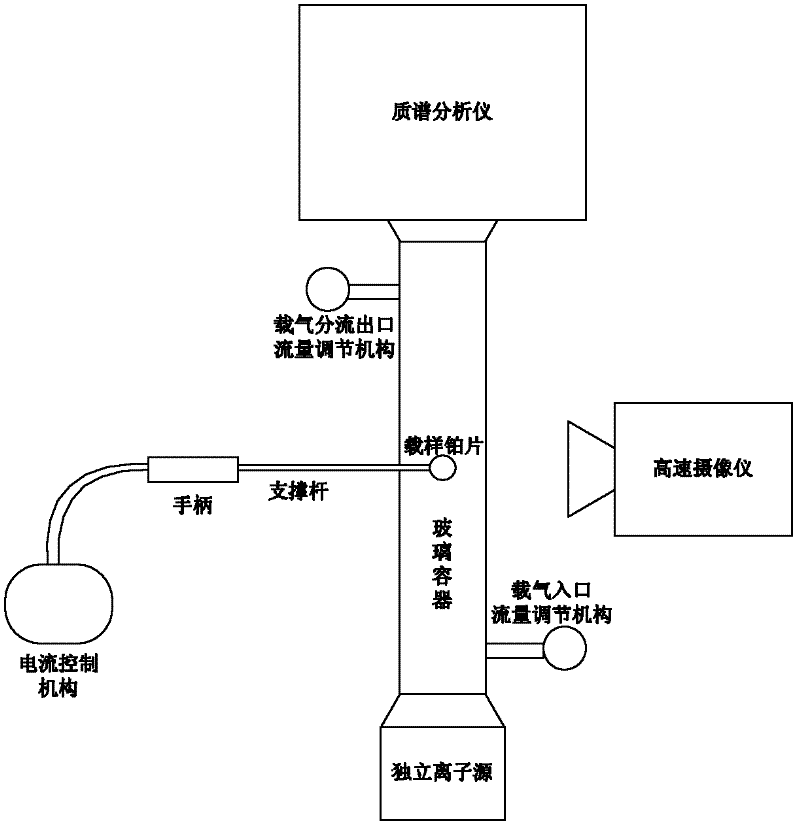

Embodiment 1

[0044] The Huolinhe coal is crushed and dried into pulverized coal with a diameter of less than 0.5mm. After drying at 120°C, 50 mg of the pulverized coal sample is placed on a metal platinum sheet, and the micro thermal conversion reactor is closed; quadrupole-time-of-flight mass spectrometry analysis The instrument (MicroTOF-QII, Bruker, Germany) is turned on and in a stable state, and is analyzed in full scan mode. The mass spectrometer can complete 20 full scans per second, and the mass spectrum mass range is set here to be 50-2000; the He carrier gas is turned on And set the carrier gas flow rate to 10L / min, do not open the split port; turn on the independent ion source (Dart-SVP, American Ironsense Company); after 30 minutes of stabilization, turn on the high-speed camera (VW-6000, Japan Keyence Company) and adjust the focus to The clearest picture; heat the metal platinum sheet with electricity, set the heating rate at 6000°C / min, heat it up to 800°C and keep it warm for...

Embodiment 2

[0046] The straw is crushed and dried into a powder with a diameter of less than 1mm, and after being heated to 120°C for drying, 40 mg of the powder sample is placed in a quartz boat wrapped around a platinum wire, and the micro thermal conversion reactor is closed; the quadrupole-time-of-flight mass spectrometer (MicroTOF-QII, Bruker, Germany) is turned on and in a stable state, and is analyzed in full scan mode. The mass spectrometer can complete 20 full scans per second. Here, the mass spectrometer mass range is set to 50-1500; the He carrier gas is turned on and set The carrier gas flow rate is 20L / min, and the split flow rate is 5L / min; turn on the independent ion source (Dart-SVP, Ironsense, USA); after 30 minutes of stabilization, turn on the high-speed camera (VW-6000, Keyence, Japan) and adjust the focus to the clearest image ; Turn on the electricity to heat the platinum wire, set the heating rate to 30°C / min, and raise the temperature to 800°C. The high-temperature ...

Embodiment 3

[0048] Cut waste plastic bags into 2-5mm pieces 2 Take 5 mg of the sample and place it on a metal platinum sheet, and close the miniature thermal conversion reactor; the quadrupole-time-of-flight mass spectrometer (MicroTOF-QII, Bruker, Germany) is in a power-on and stable state, and is analyzed in full-scan mode , the mass spectrometer can complete 20 full scans per second, here set the mass spectrometer mass range 50-2500; turn on the N2 carrier gas and set the carrier gas flow rate to 30L / min, the split flow rate to 25L / min; turn on the independent ion source (Dart-SVP , Ironsense, USA); after stabilizing for 30 minutes, turn on the high-speed camera (VW-6000, Keyence Company, Japan) and adjust the focus to the clearest picture; turn on the electricity to heat the metal platinum sheet, set the heating rate to 300°C / min, and raise the temperature to 1000°C. The high-temperature gas phase components obtained by pyrolysis enter the mass spectrometer under the carrier gas for r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com