Permanent magnet system for room-temperature magnetic refrigerator

A room temperature magnetic refrigerator and permanent magnet technology, applied in refrigerators, refrigeration and liquefaction, machines using electric/magnetic effects, etc., can solve the problem of increasing the use and maintenance costs of room temperature magnetic refrigerators, and poor uniformity of air gap field strength , magnetic working medium box force asymmetry and other problems, to achieve the effect of compact structure, simple structure and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

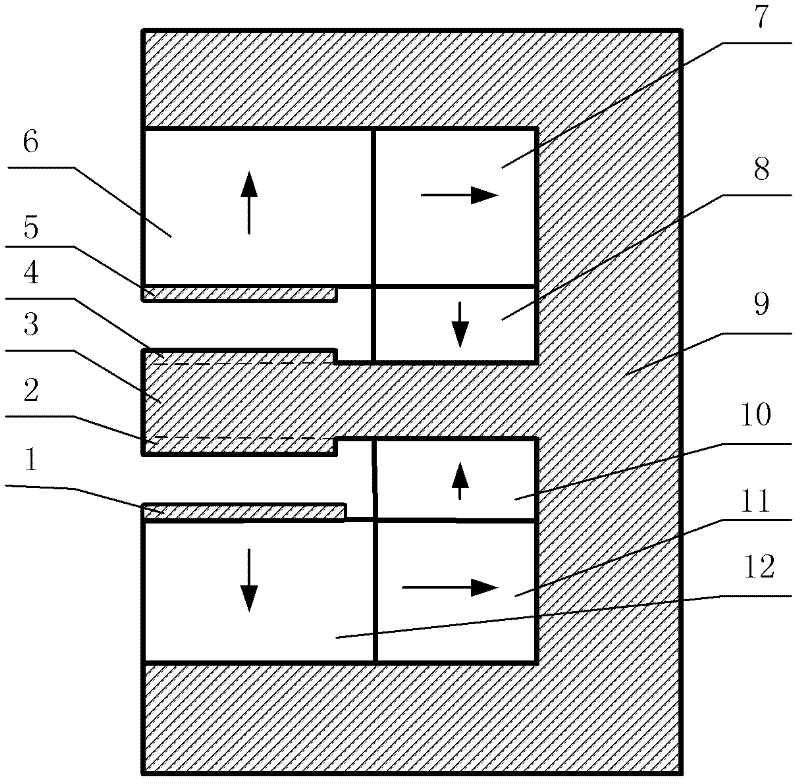

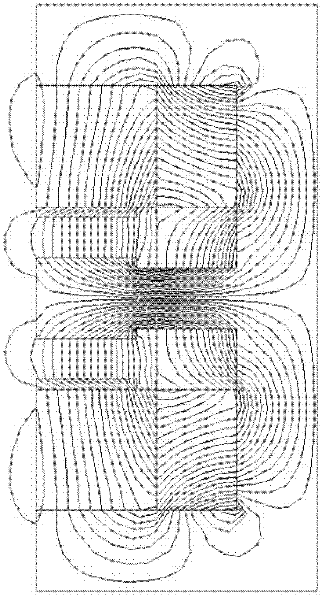

[0026] A permanent magnet system for a room temperature magnetic refrigerator, including a permanent magnet providing an excitation source and an E-shaped magnetic permeable frame 9 that acts as a magnetic conductor. The magnetic core 3 in the middle of the magnetic permeable frame 9 divides the entire frame into upper and lower parts. Section, the outer end of the magnetic core 3 is a platform structure protruding up and down; the width of the protruding platform accounts for 40% of the width of the magnetic core.

[0027] Two layers of magnetically permeable materials 1 and 5 are respectively arranged in the upper and lower sections, and the magnetically permeable materials 1 and 5 are fixed on the E-shaped magnetically permeable frame 9 . The outer ends of the magnetic-conductive materials 1,5 are flush with the outer ends of the magnetic core 3, and there is a gap between the inner end and the inner wall of the frame 9, and a gap is formed between the magnetic-conductive ma...

Embodiment 2

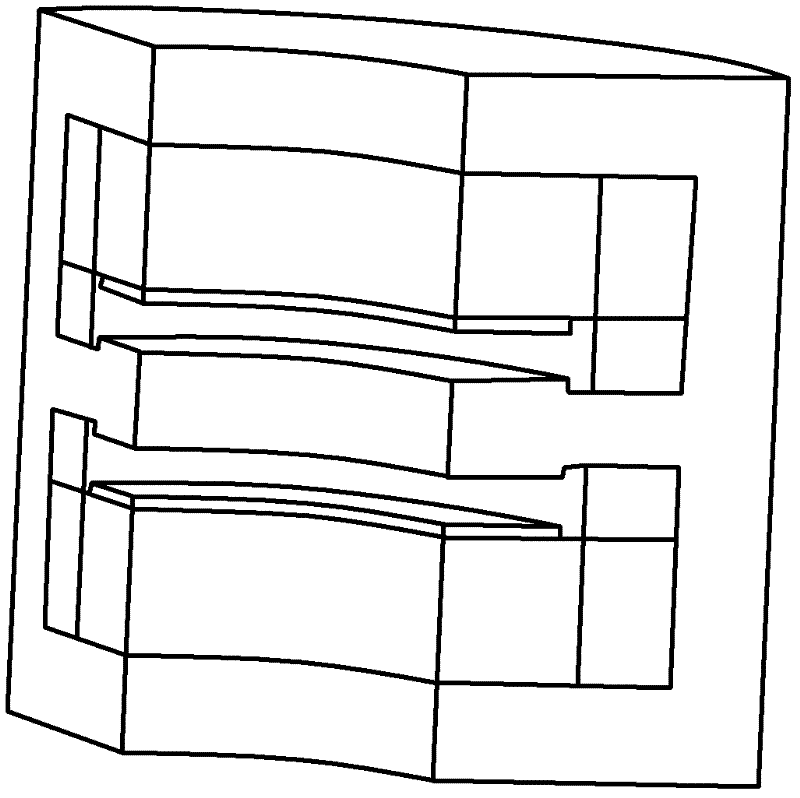

[0033] The difference between this embodiment and Embodiment 1 is that the permanent magnet system is processed into a straight line (that is, the cross section is rectangular), which is used for the magnet system of a reciprocating magnetic refrigerator, such as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com