Multi-functional ferrite core

A ferrite magnetic, multi-purpose technology, applied in the direction of transformer/inductor core, inductor/transformer/magnet manufacturing, electrical components, etc. Outlets, large ferrite cores, etc., to achieve good magnetic shielding effect, facilitate high power density and miniaturized design, and maintain consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

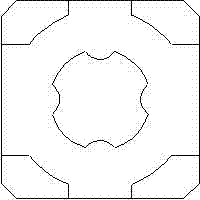

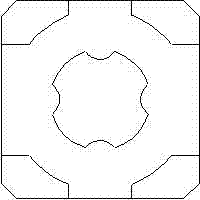

[0014] Low-profile multi-purpose ferrite core is made of soft ferrite into the shape as shown in the figure. The bottom surface or bottom plate is square or rectangular, with a cylinder 1 at the center, and four lead slots 2 on the outer edge of the cylinder to facilitate the connection of multilayer PCB windings. On the four corners of the square or rectangle are respectively side legs 3 with a nearly polyhedral cross-sectional shape. The shapes of these side legs are irregular, but they do not affect the function and effect of the magnetic core of the present invention.

[0015] The above parts cooperate with a square or rectangular magnetic sheet of the same size or with a part of the same shape and size to form a magnetic core with a closed magnetic circuit. There is an air gap or no air gap at the fit of the central cylinder. If there is an air gap, the size of the air gap is 0.01mm to 2mm.

[0016] The thickness of the bottom plate and the paired magnetic sheet is 0.4mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com