Novel movable core used for an alternating current arc welding machine

An AC arc welding machine and moving iron core technology, applied in arc welding equipment, welding equipment, transformer/inductor magnetic core and other directions, can solve the problems of poor arc stability, short-circuit ring heating, small no-load loss, etc. Low, convenient processing and installation, the effect of relatively small space area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

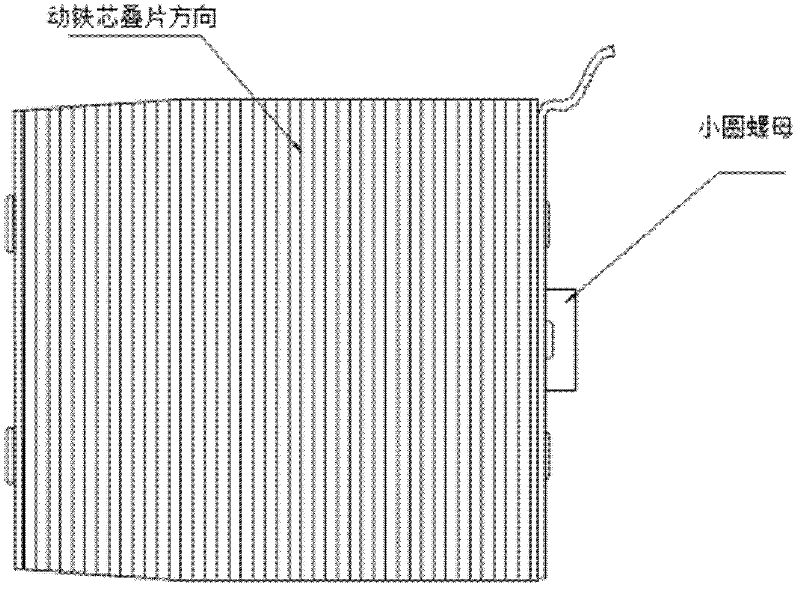

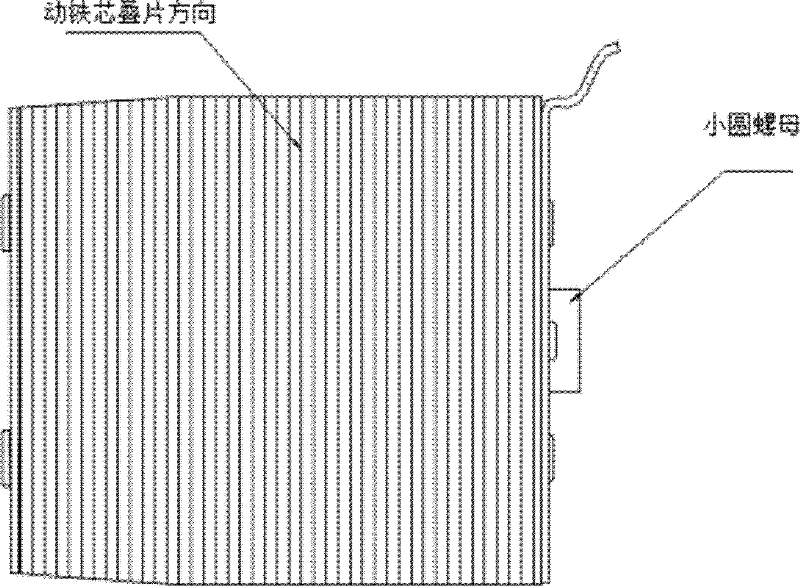

[0011] Such as figure 1 As shown, a new type of moving iron core for AC arc welding machine according to the present invention adopts a rectangular design, and the new type of moving iron core is provided with several laminations, and its direction is the same as that of the static iron core laminations; The adjusting screw on one side of the new moving iron core is also provided with a small round nut, and the lamination direction of the new moving iron core is adjusted by pulling the small round nut back and forth.

[0012] The invention has the beneficial effects of ingenious design, simple structure, small space area, convenient processing and installation, and low loss. The design of the rectangular moving iron core completely solves the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com