Double-sided butt riveting structure of circulator/isolator shell

A butt riveting and isolator technology, which is applied in the field of gold processing, can solve the problems of poor sealing and riveting fastness, and achieve the effects of high riveting strength, good anti-magnetic leakage sealing performance, and convenient processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

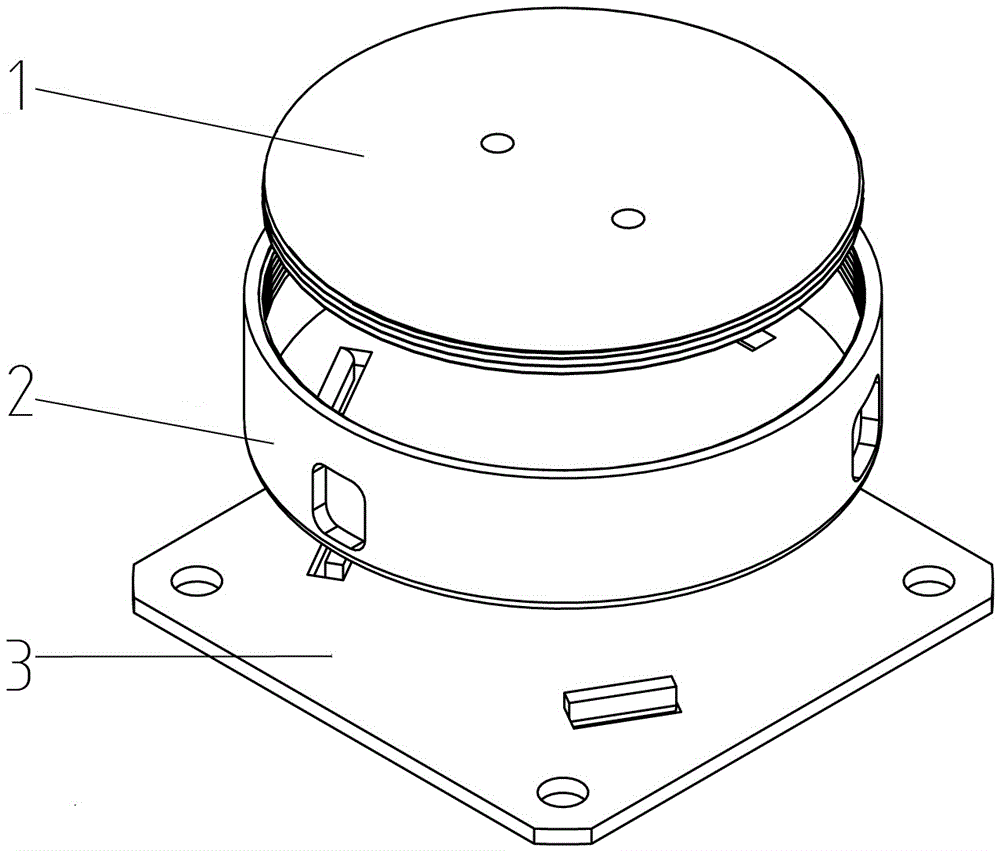

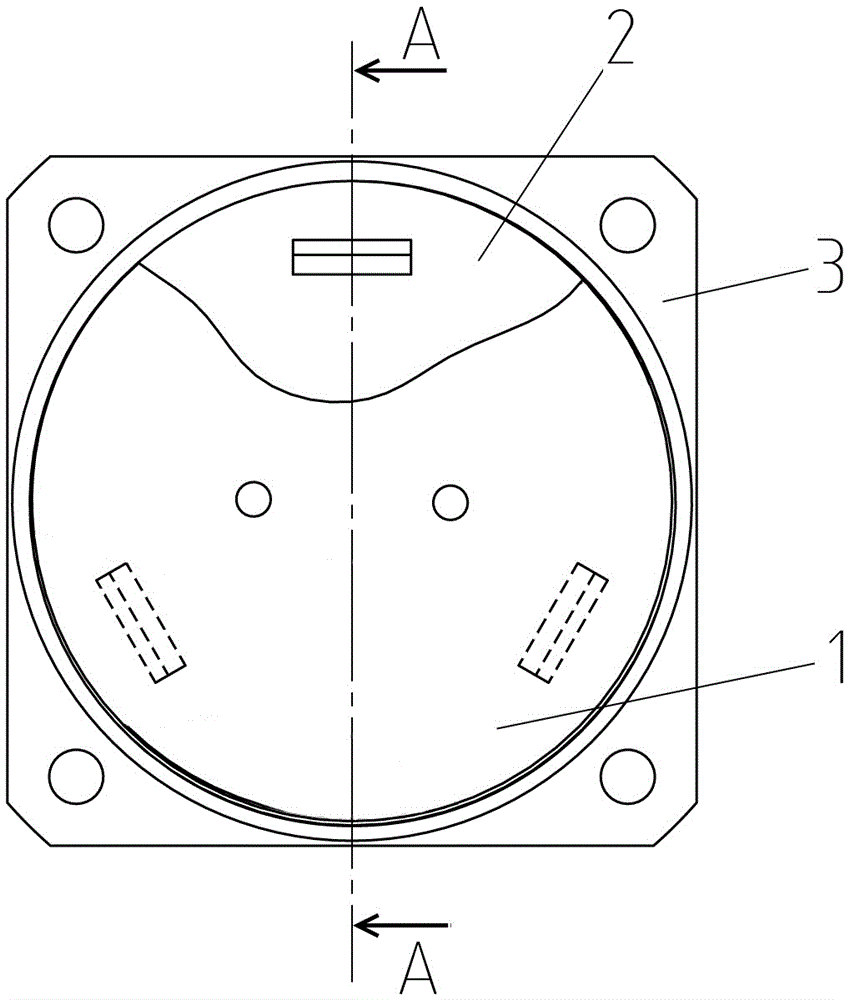

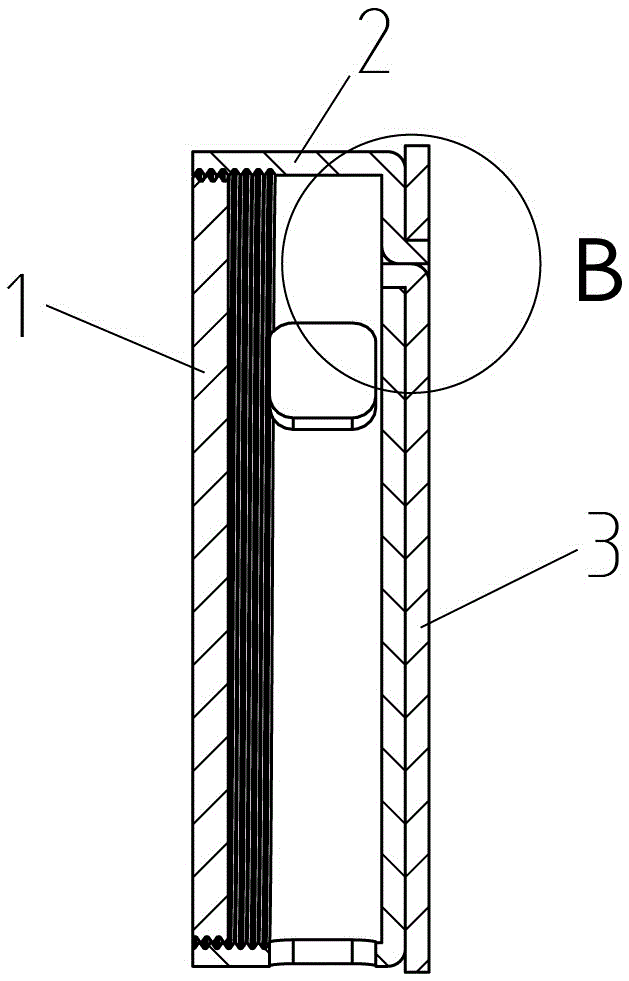

[0014] Figure 2 ~ Figure 4 These are the structural schematic diagram and the partial cross-sectional enlarged structural diagram of the present invention. It can be seen from the figure that the double-sided butt-jointed riveting structure of the circulator / isolator body includes a cover 1, a body body 2 and a base 3, the cover 1 and the body The threaded connection between the main bodies 2 is characterized in that: the corresponding positions of the main body 2 and the base 3 are respectively provided with riveting protrusions and riveting holes, and the riveting holes of the main body 2 are provided with base riveting protrusions. Step 5, the body shell body riveting protrusion 4 is placed in the riveting hole of the base 3, and the two sides are butted and riveted and fixed.

[0015] During processing, the cavity of the trunk body 2 is formed by drawing and stamping. The riveting holes and riveting protrusions on the bottom of the cavity of the trunk body 2 and the base, as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com