Method for repairing damage of external shield of medium and high voltage cable

A technology for medium and high voltage cables and a repair method, applied in the field of wires and cables, can solve the problems of increased inventory, damage, thermal expansion of insulation, etc., and achieves low economic cost, guaranteed shielding effect, and tight integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

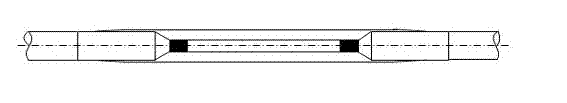

[0012] A method for repairing damage to the outer shield of medium and high voltage cables, the operation steps are as follows:

[0013] 1. Clean the damaged outer shielding and insulation surface: When performing surface treatment on the damaged outer shielding and insulation, use conventional methods to scrape the damaged part of the insulation until it is qualified, and try to ensure that the insulation thickness is uniform and uniform; the damaged and undamaged parts of the outer shield It is connected in a sloped way, that is, the two ends of the damaged outer shielding surface are cut into cones; finally, the insulating surface is wiped several times with alcohol and cleaning paper until it is wiped clean; the length of the treated surface must not only be greater than the damaged length , And make sure to wrap both ends of the insulation.

[0014] 2. Use the outer semi-conductive material to completely wrap around the damaged part, and then use polyester tape or polytetraf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com