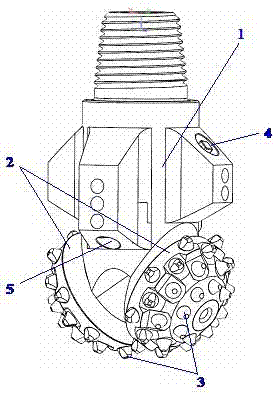

Wheel type drill bit for breaking rock by rotary cutting

A drill bit and rock-breaking technology, which is applied in the field of wheeled drill bits that break rock by rotary cutting, can solve problems such as low rock-breaking efficiency, short bearing life, and poor wear resistance of teeth, so as to improve the bearing structure of the drill bit and solve rock-breaking problems. High efficiency and rock-breaking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

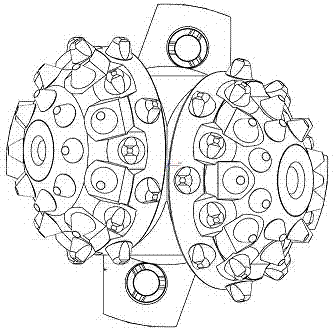

[0052] When the rotary cutting drill bit of the present invention , ,diameter , the drilling speed is , the materials used in the experiment were Hongya stone: , green sandstone: During the experiment, rock cuttings were collected, the difficulty of rock breaking and vibration were analyzed, the wear marks and directions of cutting teeth were checked, and the wheel body speed ratio of the cone and the drill bit was calculated.

[0053] The results of the examples and the theoretical calculations also show that: under the corresponding parameter conditions in Example 1, the wheel body speed ratio is less than 1, and in this example it is less than 0.55; the harder the lithology, the higher the cone speed, and the higher the wheel body speed ratio.

Embodiment 2

[0055] when gear 2 , ,diameter , the drilling speed is , the materials used in the experiment are Hongya stone: , green sandstone: During the experiment, rock cuttings were collected, the difficulty of rock breaking and vibration were analyzed, the wear marks and directions of cutting teeth were checked, and the wheel body speed ratio of the cone and the drill bit was calculated.

[0056] Embodiment result and theoretical calculation show simultaneously: corresponding , the harder the lithology, the lower the speed of the cone, and the speed ratio of the wheel body is smaller than the value corresponding to Example 1.

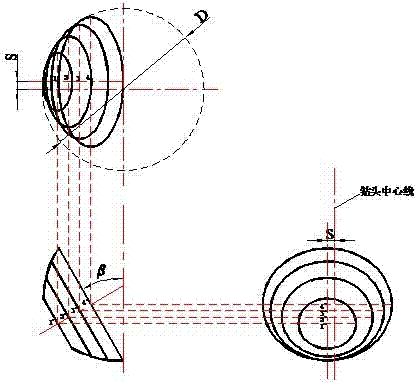

[0057] Comprehensive comparative analysis of the above implementation results can be obtained: Optimizing the included angle of the wheel body and journal offset values , can achieve the purpose of increasing the slippage of the cone cutter at the bottom and wall of the well, reducing the speed ratio of the wheel body, and improving the rock-bre...

Embodiment 3

[0058] Embodiment 3: the cone is one

[0059] The working face of the cone faces between the well wall and the bottom of the well, and the angle between the journal plane of the upper cone of the main body (1) and the axis of the drill bit in the range of , the journal offset is , the large ring tooth of the tooth wheel cuts the heart.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com