Cutthrough grounding cable applied in railway signal system

A technology for grounding cables and railway signals, applied to insulated cables, cables, circuits, etc., can solve the problems of high manufacturing cost and achieve the effects of low manufacturing cost, good electrical performance, considerable economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

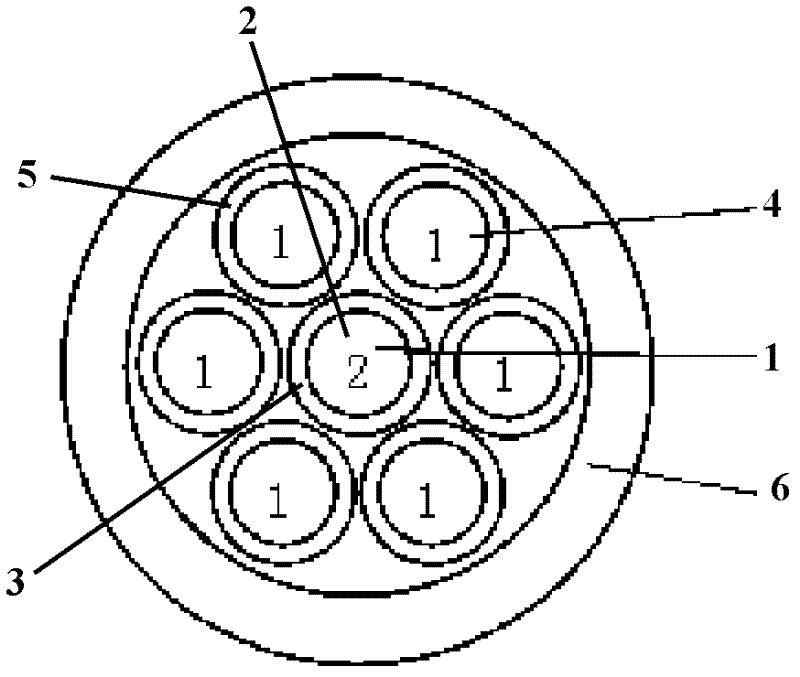

[0022] Embodiment 1: A kind of penetrating grounding cable applied to railway signal system, as attached Figure 1-2 As shown, it includes: a grounding steel wire group 2 composed of at least one steel wire 1 twisted, the surface of the steel wire 1 is coated with a second copper layer 3 with a purity of 99.95% or more, and at least 6 aluminum wires 4 twisted A grounding aluminum wire layer is formed on the surface of the grounding steel wire group 2, and the surface of the aluminum wire 4 is coated with a first copper layer 5 with a purity of 99.95% or more;

[0023] Both the thickness of the first copper layer 5 and the second copper layer 3 are 0.10 mm to 0.50 mm;

[0024] A conductive sheath 6 with a volume resistivity of less than 0.65Ω.cm is coated on the surface of the grounded aluminum wire layer, and the conductive sheath 6 is composed of the following components:

[0025] Polyethylene 70%~80%,

[0026] Conductive carbon black 10% ~ 15%,

[0027] Plastic conductive...

Embodiment 2

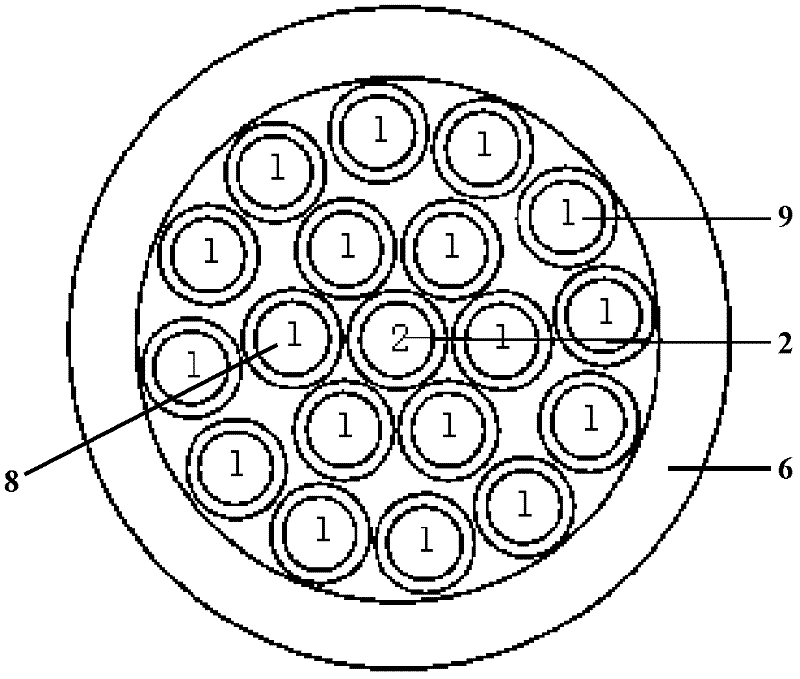

[0030] Embodiment 2: A kind of penetrating grounding cable applied to railway signal system, as attached figure 1 , 3 As shown, it includes: a grounding steel wire group 2 composed of at least one steel wire 1 twisted, the surface of the steel wire 1 is coated with a second copper layer 3 with a purity of 99.95% or more, and at least 6 aluminum wires 4 twisted A grounding aluminum wire layer is formed on the surface of the grounding steel wire group 2, and the surface of the aluminum wire 4 is coated with a first copper layer 5 with a purity of 99.95% or more;

[0031] Both the thickness of the first copper layer 5 and the second copper layer 3 are 0.10 mm to 0.50 mm;

[0032] A conductive sheath 6 with a volume resistivity of less than 0.65Ω.cm is coated on the surface of the grounded aluminum wire layer, and the conductive sheath 6 is composed of the following components:

[0033] Polyethylene 70%~80%,

[0034] Conductive carbon black 10% ~ 15%,

[0035] Plastic conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com