PET (polyethylene terephthalate) composite material for beer packaging and its preparation technology

A composite material and preparation process technology, applied in the field of polyester composite material and its preparation process, can solve the problems of limiting the application range of PET, insufficient strength, etc., and achieve the effects of low processing cost, low manufacturing cost, and easy processing and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The PET composite material for beer packaging of the present embodiment is composed of the following components in parts by weight: 62.9 parts of polyethylene terephthalate, 35 parts of glass fibers, 10 parts of interfacial compatibilizer PP-g-MAH, Antioxidant 1010 is 0.05 parts, dicumyl peroxide is 0.05 parts, and stearic acid is 2 parts.

[0024] Its preparation process comprises the following steps:

[0025] (1) Weigh polyethylene terephthalate, glass fiber, interfacial compatibilizer PP-g-MAH, antioxidant 1010, dicumyl peroxide, stearic acid according to the above weight ratio, and then place Mix in a high-speed mixer for 10 minutes;

[0026] (2) Place the mixture obtained in step (1) in a co-rotating parallel twin-screw extruder, melt extrude, and granulate. The process parameters are as follows: the temperature of the first zone is 240°C, the temperature of the second zone is 250°C, and the temperature of the third zone is 260°C ℃, the temperature of the fourth ...

Embodiment 2

[0030] The PET composite material for beer packaging of the present embodiment is composed of the following components in parts by weight: 67.9 parts of polyethylene terephthalate, 30 parts of glass fibers, 10 parts of interfacial compatibilizer PP-g-MAH, Antioxidant 168 is 0.05 parts, dicumyl peroxide is 0.05 parts, and stearic acid is 2 parts.

[0031] Its preparation process is with embodiment 1.

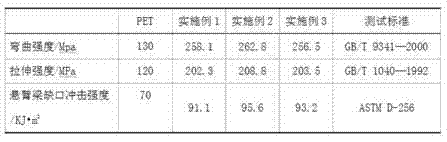

[0032] Carry out performance test to the product of this embodiment, its test method standard number and result are shown in Table 1.

Embodiment 3

[0034] The PET composite material for beer packaging of the present embodiment consists of the following components in parts by weight: 72.9 parts of polyethylene terephthalate, 25 parts of glass fiber, 10 parts of interfacial compatibilizer PP-g-MAH, anti- Oxygen agent 1010 is 0.05 parts, dicumyl peroxide is 0.05 parts, and stearic acid is 2 parts.

[0035] Its preparation process is with embodiment 1.

[0036] Carry out performance test to the product of this embodiment, its test method standard number and result are shown in Table 1.

[0037] Table 1 Example 1-3 Product Performance Test Method Standard Number and Results

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com