Solvent-free double-component epoxy resin adhesive and preparation method and application thereof

A technology of epoxy resin glue and epoxy resin, which is applied in the direction of epoxy resin glue, adhesive additives, polymer adhesive additives, etc., can solve the problem of poor rotational stretching ability of chain segments, loss of cohesive force, and brittleness cracking peel strength and other issues, to achieve the effect of good shear resistance, excellent adhesion, high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 8

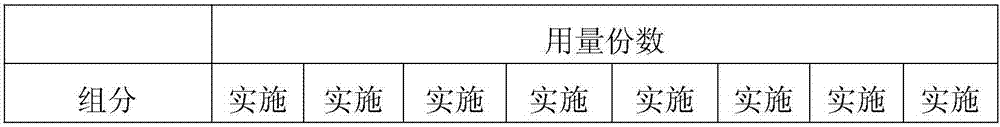

[0024] Preparation of a two-component epoxy resin adhesive and its use are shown in Table 1.

[0025] Table 1 Preparation of two-component epoxy resin adhesive raw material components and their proportions

[0026]

[0027]

[0028] 1. The preparation method of solvent-free two-component epoxy resin adhesive, the steps are as follows:

[0029] (1) Add polyether polyol N210, polyether polyol N220, and polyester polyol 1330 into the container according to the parts by weight in the above table 1, and stir at 80° C. for 15 min;

[0030] (2) Add isocyanate TDI to the reaction system of step (1) several times, stir at 80°C for 2h; add epoxy resin E-51, heat up to 95°C, stir for 2.5h, and the reaction is over to obtain a modified epoxy resin ,spare;

[0031] (3) Take the above modified epoxy resin and epoxy curing agent T31, mix and stir evenly in a ratio of 14:1, add 12 parts of acetone to adjust the viscosity, and prepare 8 parts of epoxy resins made from raw materials in ...

Embodiment 9

[0032] Embodiment 9 performance test, concrete steps are as follows:

[0033] 1. Polish the wooden substrate to make it smooth, and apply the epoxy resin adhesive prepared in the above examples 1 to 8 according to the amount of 2kg of glue per square meter, and wait for the solvent on the bonding surface to evaporate for a few minutes. Lay the adhesive surface together, compact it, and cure it at room temperature for 1 hour to have a high adhesive force, and 24 hours to reach the highest adhesive force;

[0034] The modified epoxy resin glue after curing was measured for the following properties:

[0035] (1) Shear strength; (2) Peel strength; (3) Adhesive strength of bonded wood boards after soaking in water for 120 hours at room temperature; (4) Adhesive strength of bonded glass plates after soaking in water for 240 hours at room temperature .

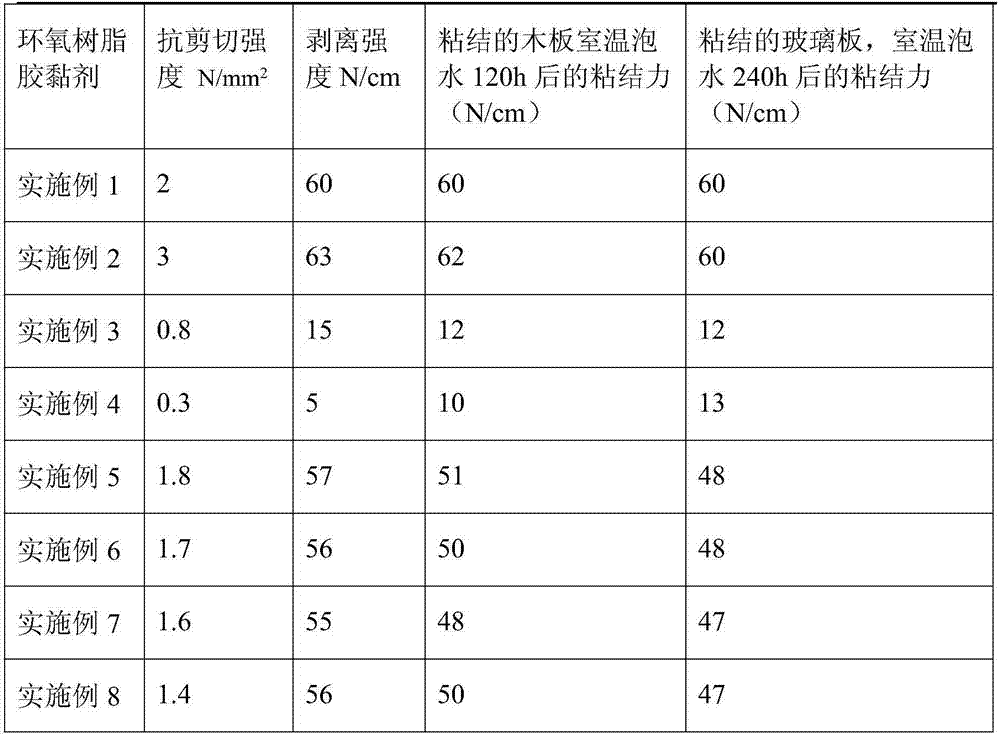

[0036] The specific inspection results are shown in Table 2:

[0037]

[0038] The results of the above performance tests sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com