Efficient method and pump valve integrated energy-saving device for water pump

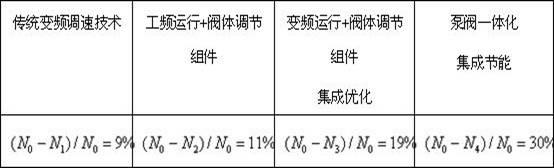

An energy-saving device and water pump technology, applied in pump control, liquid variable capacity machinery, machine/engine, etc., can solve problems such as unsatisfactory energy-saving effect, and achieve the effect of improving the energy efficiency of the main engine, optimizing the operating energy efficiency, and obvious energy-saving benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

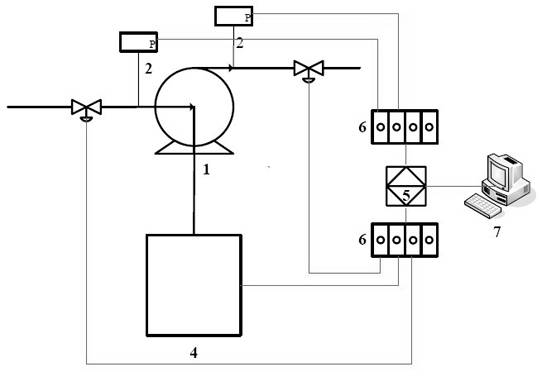

[0038] Embodiment 1: The figure shows a schematic diagram of the technical process of pump-valve integrated joint regulation. The pressure sensors at the inlet and outlet of the water pump are sequentially connected to the DCS / PLC through the cable and through the cable terminal 6.

[0039] The operation optimization platform software 7 embeds or downloads a "single pump energy efficiency optimization program", and transfers the results of the program to the DCS / PLC device to do the following optimization work:

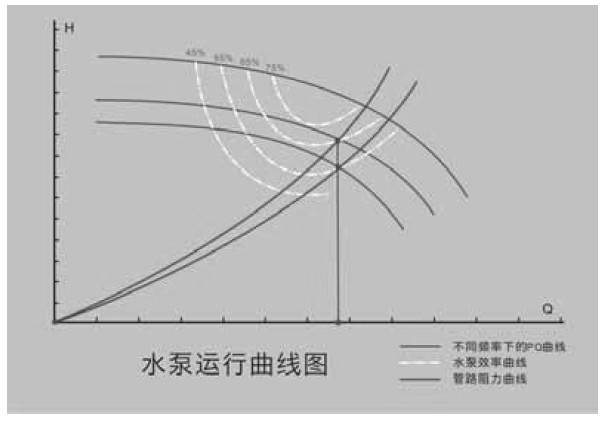

[0040] (A) Through the joint adjustment of frequency conversion and valve body adjustment components, the energy efficiency of single pump operation is optimized;

[0041] (B) The opening adjustment of the valve body adjustment assembly is combined with the cutting of the outer diameter of the impeller of the raw water pump;

[0042] (C) The opening adjustment of the valve body adjustment component is combined to change the hydraulic model of the original water pump (replace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com