Dual-descaling method for hot rolling strip steel slab

A technology for steel slabs and hot-rolled strips, applied in the field of double descaling, can solve the problems of large surface temperature drop, poor ductility, surface scarring and cracking of strip steel slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

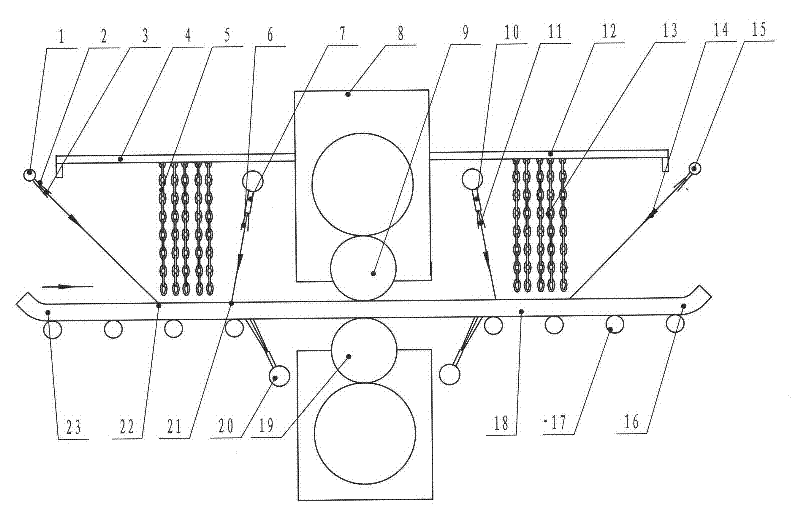

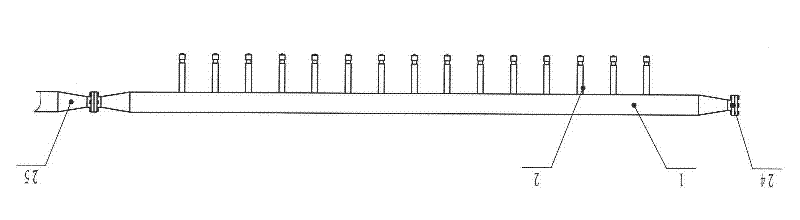

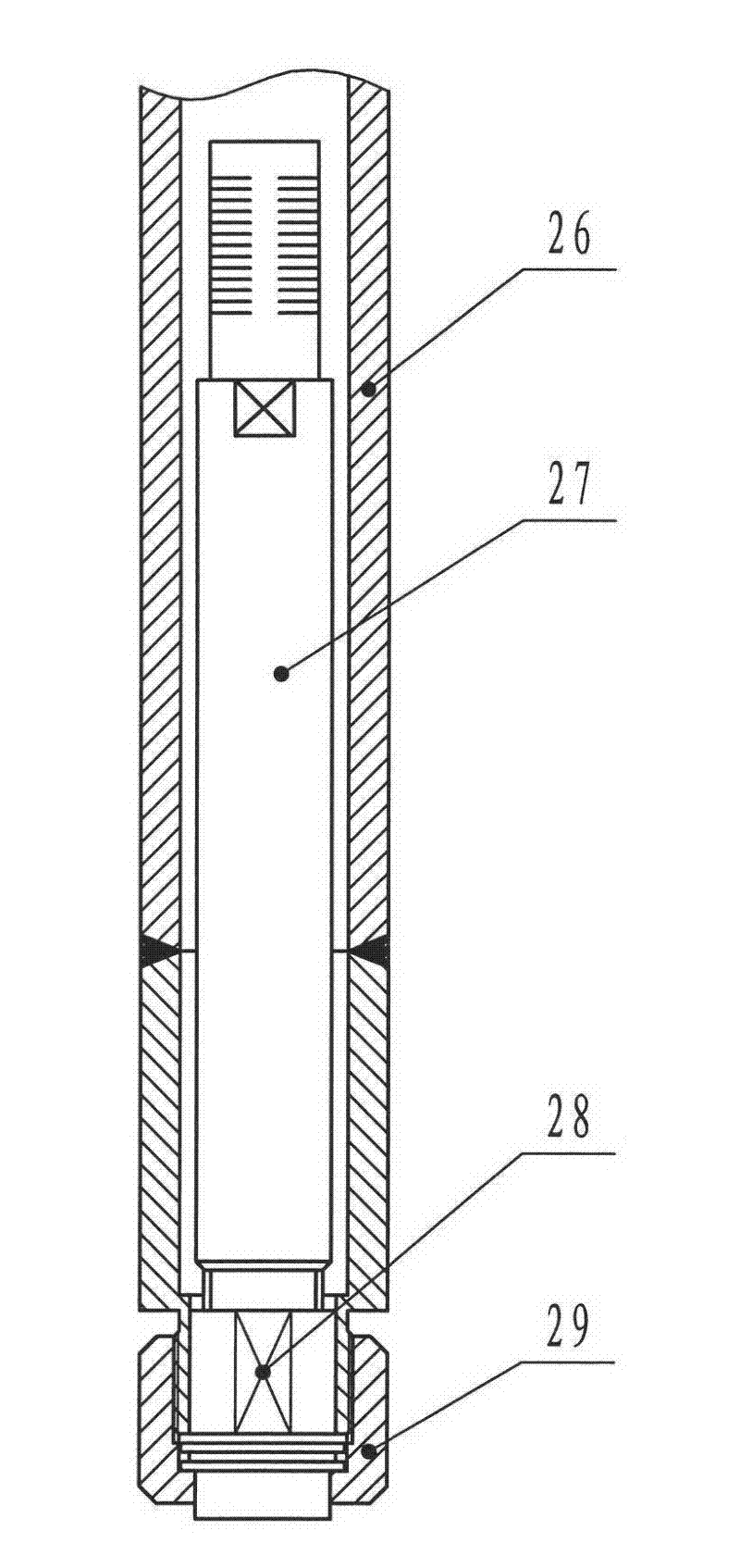

[0028] Present embodiment is implemented on the roughing mill of 2250mm hot continuous rolling production line, see figure 1 , the strip steel slab 18 of the rolling mill is 10-50 meters long, 1-2.13 meters wide, 50-250mm thick, and the initial rolling temperature is 1000°C-1100°C. A row of 22 descaling Water nozzle 7, a row of 22 descaling water nozzles 10 are installed on the outlet support 12 of the hot rolling mill, and two descale water nozzles are obliquely outward, and the angle of the relative horizontal plane is 80 °, and the water spray nozzles of each row The amount is 270 cubic meters. The double descaling method of this hot-rolled strip is to spray high-pressure descaling water obliquely outwards at the descaling water nozzle, and use the five rows of water retaining chains 5 that are installed on the roughing mill entrance support 4 to droop. Block the splashing descaling water 6 sprayed by 22 descaling water nozzles 7, and spray the descaling water sprayed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com