Air-float type film turning device used for once double-side intaglio printing of film

A technology of gravure printing and turning device, which is applied in the direction of gravure rotary printing machine, printing, printing machine, etc., can solve the problems of increased material consumption and time waste, and achieve the effect of reducing material loss, high precision and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

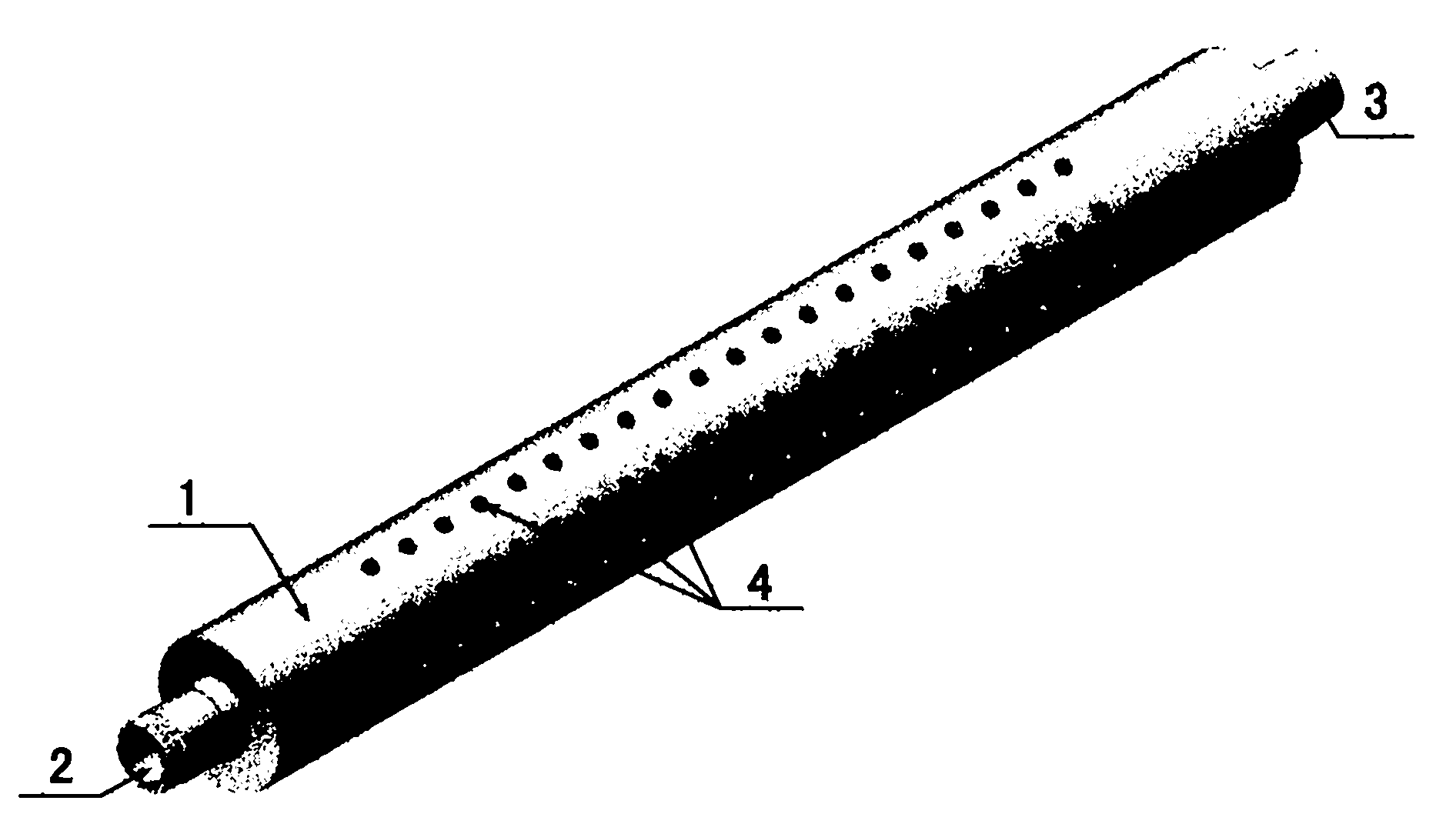

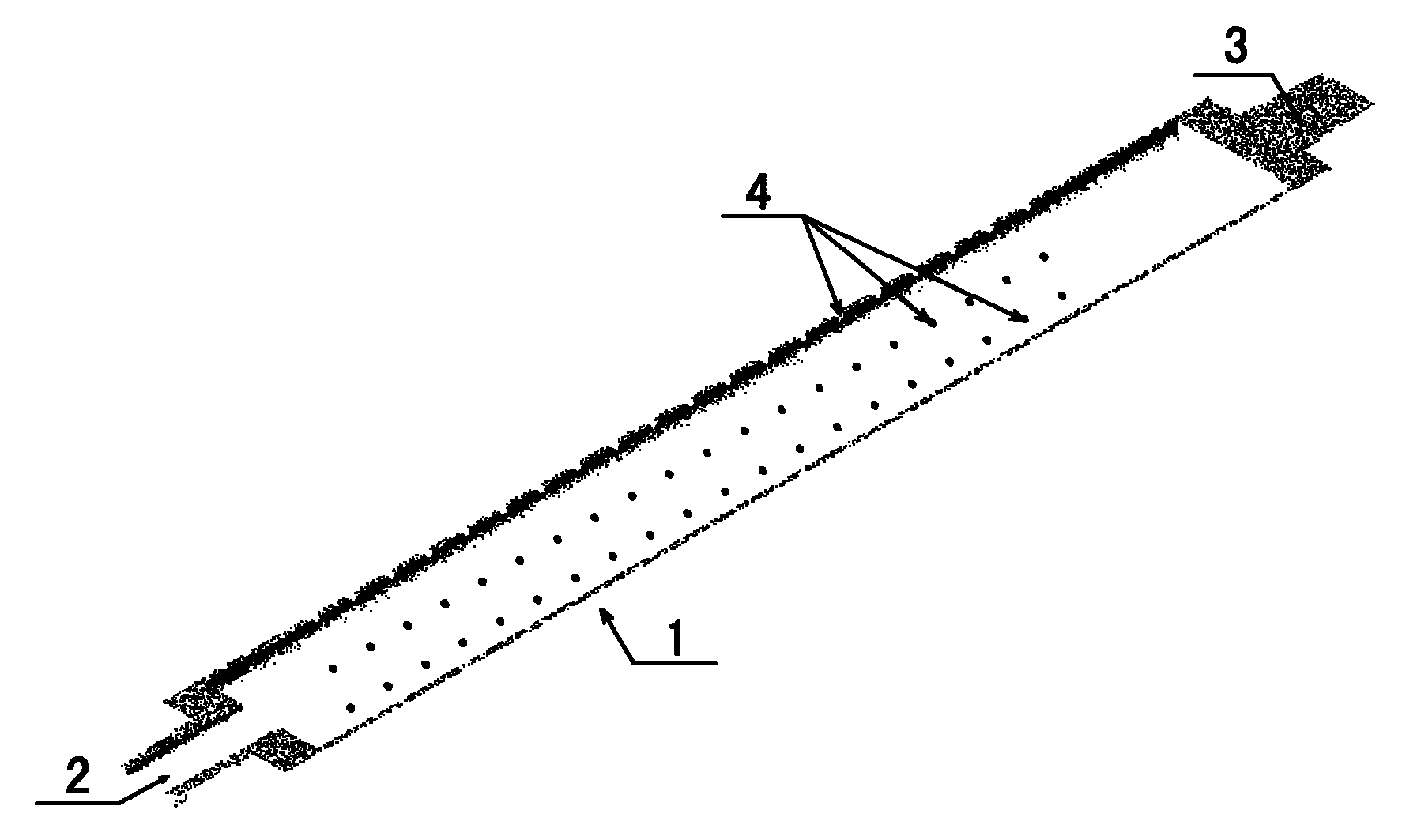

[0018] see Figure 1 to Figure 2 , The air-floating guide roller of the present invention has three rows of "horn"-shaped small air holes 4 evenly distributed on one side of the roller surface, the roller body is hollow, one end is sealed 3, and the other end is not sealed 2.

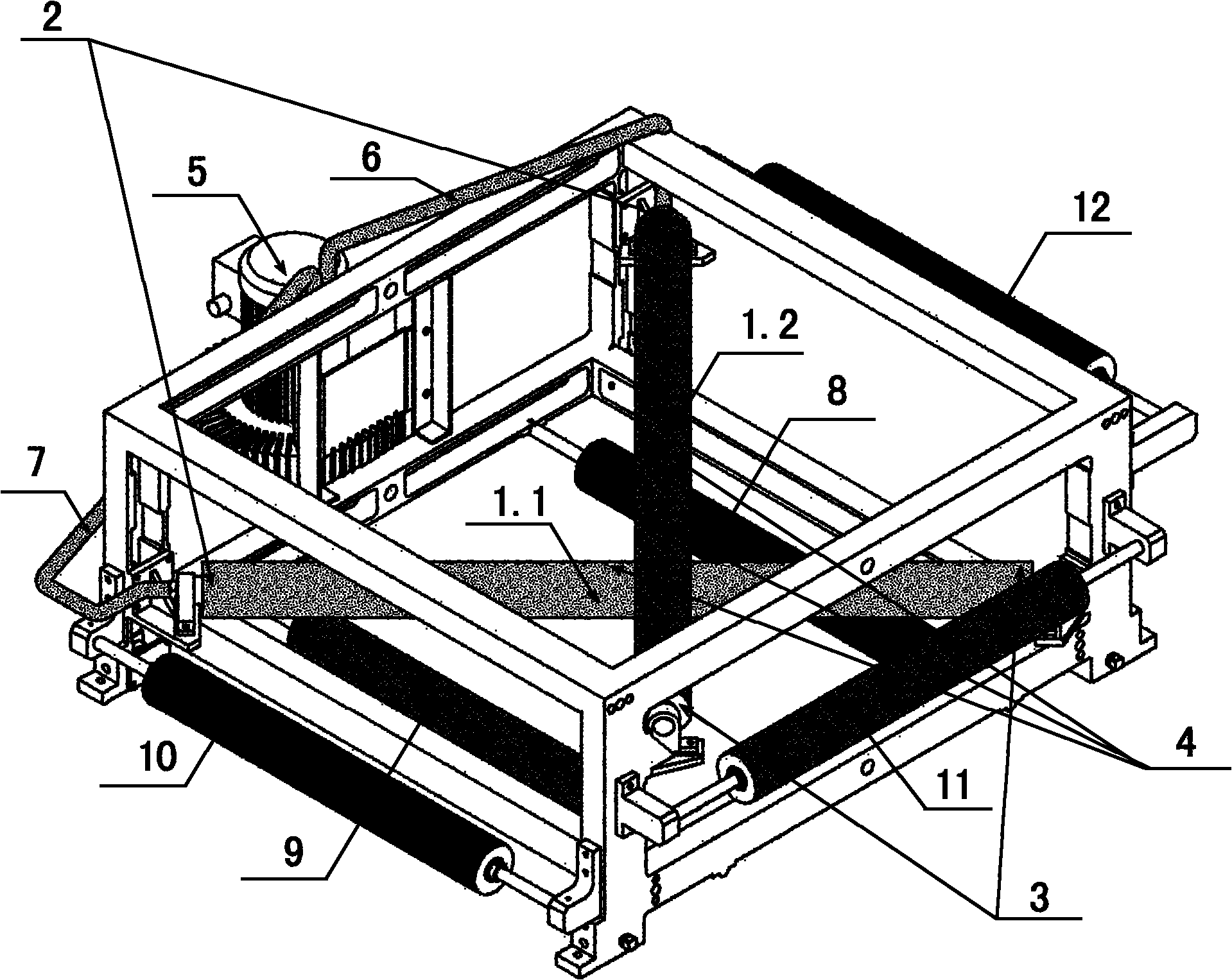

[0019] see image 3 , the present invention is mainly implemented through the following schemes:

[0020] The vortex air pump fan 5 operates to generate air pressure, and the gas is continuously fed into the roller from the unsealed end 2 of the air-floating guide roller 1 through the rubber tubes 6 and 7, and then ejected from the "horn"-shaped small air hole 4, forming a side surface. The arc-shaped air wall supports the film, so that the film does not touch the surface of the guide roller evenly during travel, and is stable and free of resistance, thereby avoiding abrasion and scratching the printing surface of the film.

[0021] According to the normal printing process, after the front printing is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com