Centrifugal pump

A centrifugal pump and pump body technology, applied in the field of centrifugal pumps, can solve the problems of accelerating the wear rate of particles on the outer wall of the box, waste of resources in production, poor wear resistance, etc., achieving novel structure, prolonging service life, and reducing wear rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

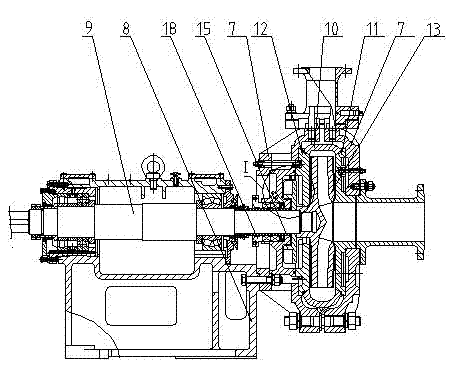

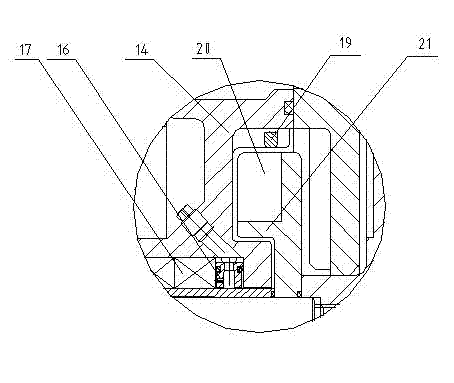

[0015] The present invention is further described below in conjunction with accompanying drawing:

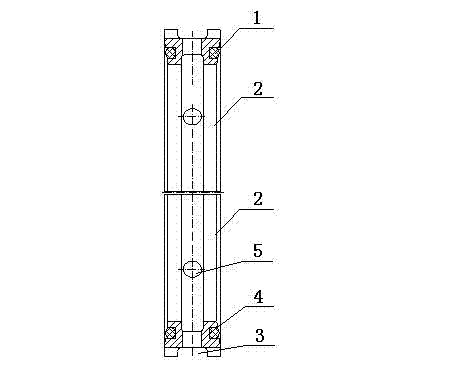

[0016] As shown in the drawings, a centrifugal pump is equipped with a pump body 7, a bracket body 8, a pump shaft 9, an inner pump casing 10, a front liner 11, a rear liner 12, an impeller 13, a sealing packing device, and a sealing packing The device is composed of stuffing box 14, stuffing bushing 15, stuffing ring 16, stuffing 17 and stuffing gland 18. The cavity of stuffing box 14 is provided with auxiliary impeller 20, pump body 7, bracket body 8, pump shaft 9, inner The connection relationship of the pump casing 10, the front liner 11, the rear liner 12, the impeller 13, the stuffing box 14, the stuffing sleeve 15, the stuffing ring 16, the stuffing 17 and the stuffing gland 18 is the same as that of the prior art, and will not be repeated here. It is characterized in that there is an O-ring 1, and the packing ring 16 is composed of at least two packing ring bodies 2. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com