High-capacity double-body split on-load voltage-regulating transformer

A voltage-regulating transformer and large-capacity technology, which is applied in the field of transformers, can solve problems such as poor safety and reliability, asymmetric ampere-turns, and uneven force on the wire cake, so as to improve safety and reliability and reduce mechanical force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

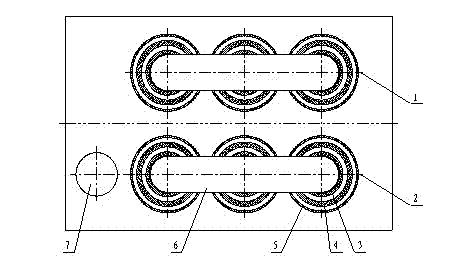

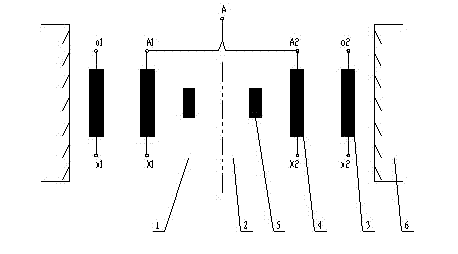

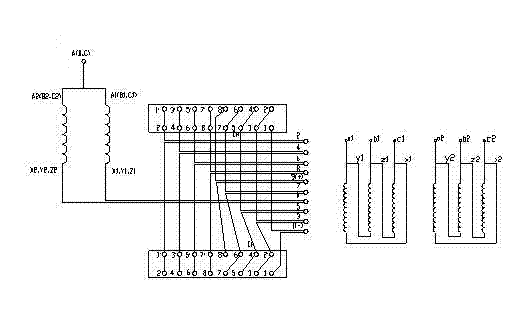

[0015] A large-capacity double-body split on-load tap-changing transformer. Two transformer bodies 1 and 2 with the same structure are arranged in the transformer oil tank, that is, two double-coil on-load tap-changing transformers whose three-phase capacity is half of the total capacity. The body of the device is placed in an oil tank, arranged parallel to the front and rear along the short axis of the transformer; the high voltage of the transformer is on-load voltage regulation, and the low voltage is split into two low-voltage windings 3; The two low-voltage windings form two angular connections; the high-voltage windings 4 and voltage-regulating windings 5 of the two core columns on each device are connected in parallel and then drawn out, and the three-phase high-voltage windings are connected in a star shape. Each device body is a three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com