Cleaning method of ion source electrode

A technology of ion sources and electrodes, applied in ion beam tubes, circuits, discharge tubes, etc., can solve problems such as difficult and high-speed removal of deposits, and achieve the effect of high-speed removal of deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

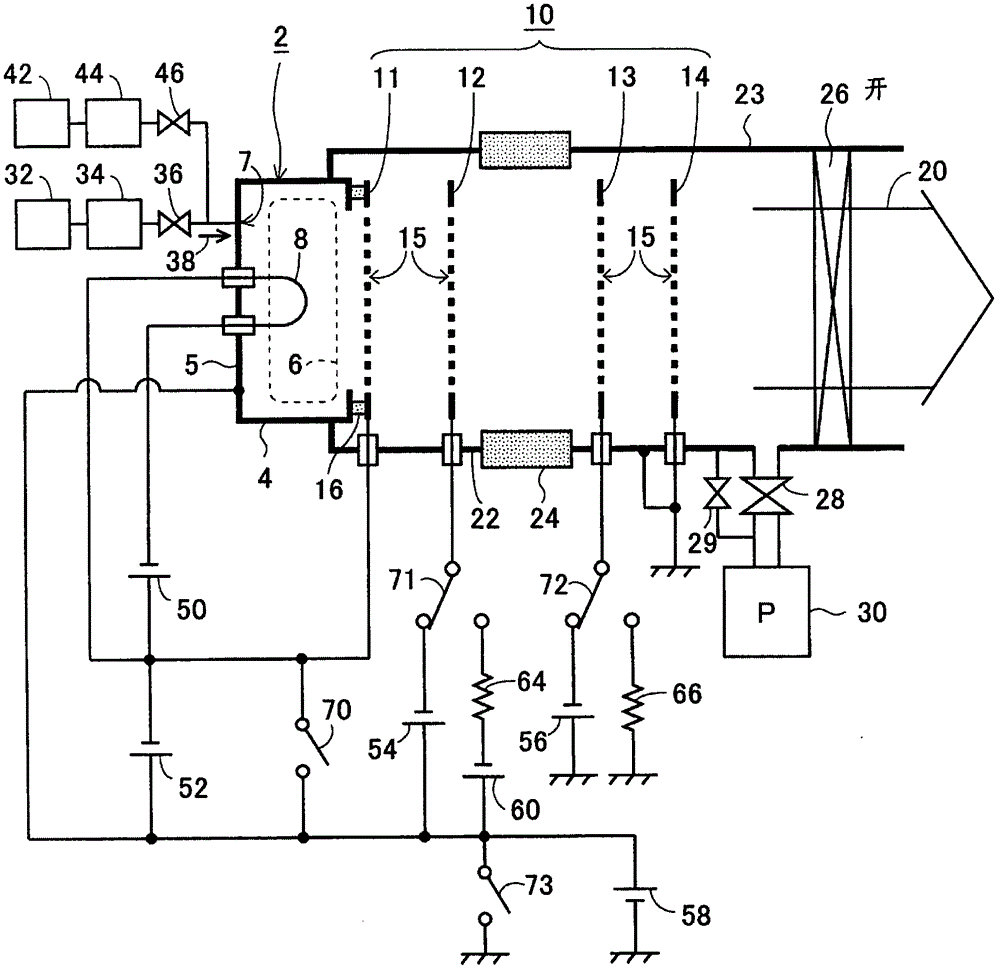

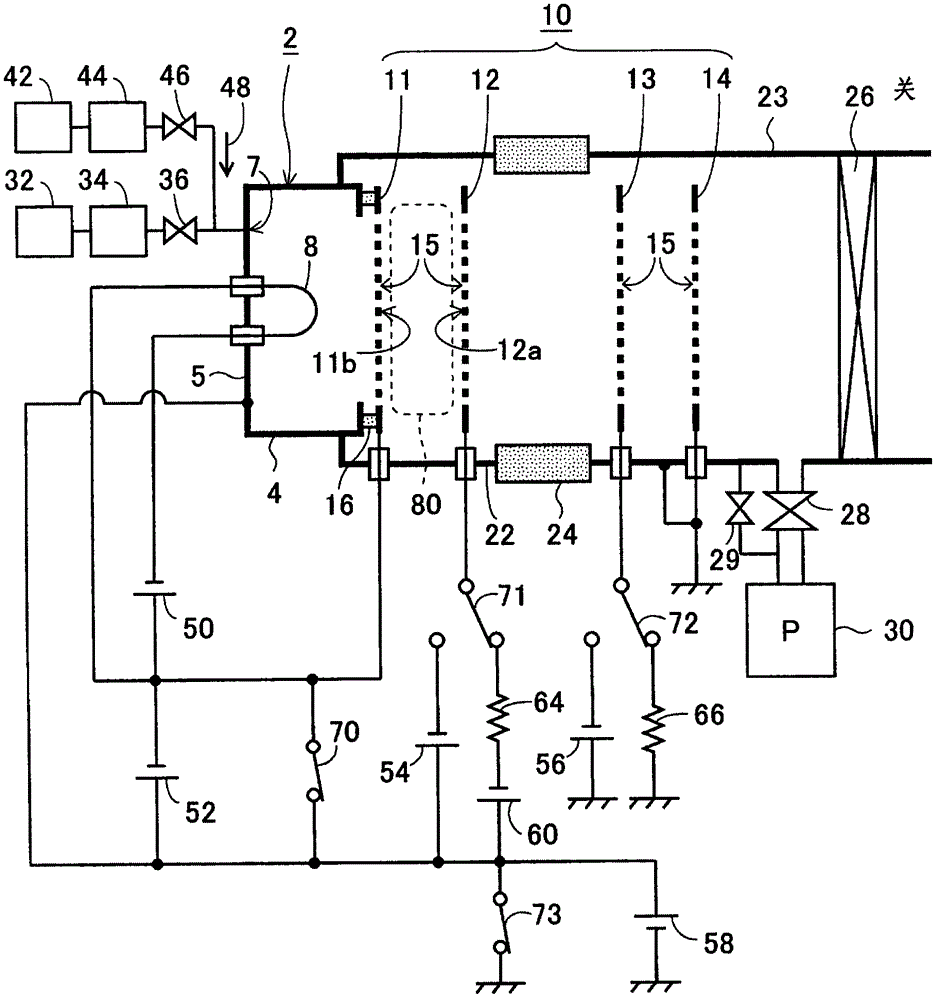

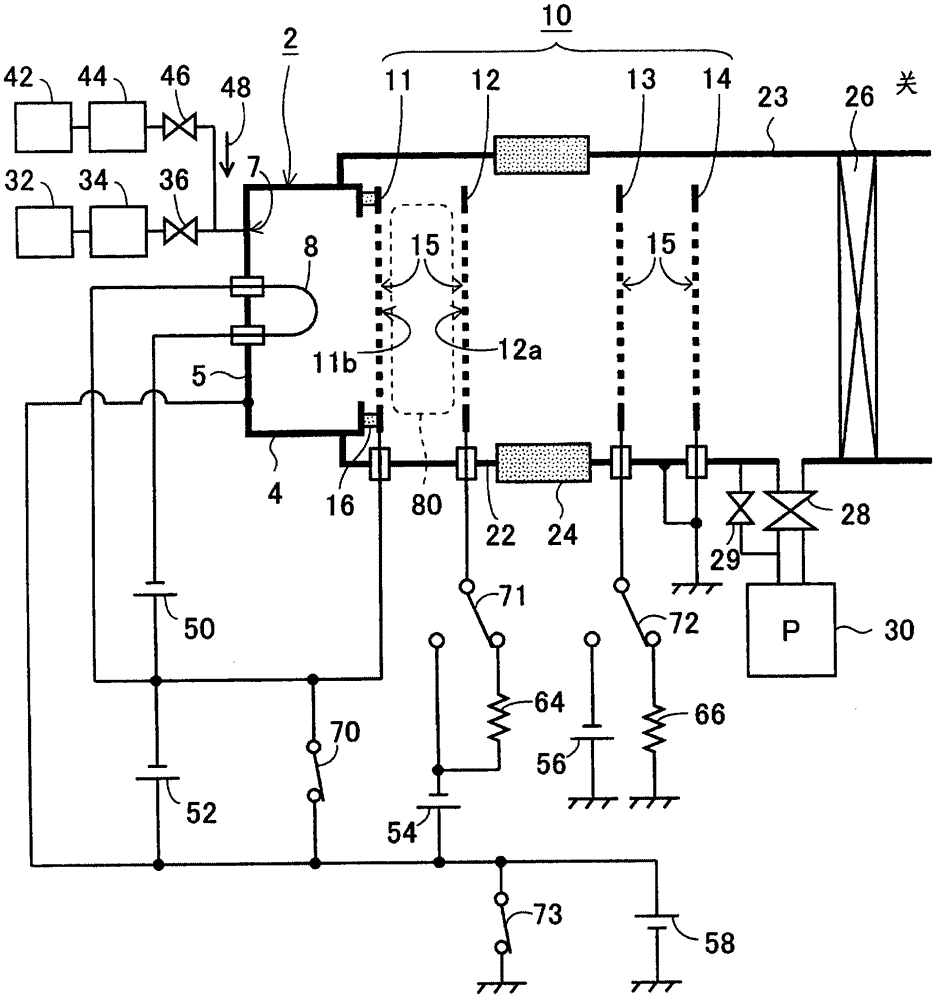

[0038] figure 1 , figure 2 An example of an ion source device for carrying out the cleaning method of the present invention is shown. figure 1 Indicates the state when the ion beam is extracted, figure 2 Indicates the status during cleaning.

[0039] The ion source 2 constituting the ion source device includes: a plasma generating part 4, which is used to introduce an ionizable gas 38 and ionize the ionizable gas 38 to generate a plasma 6; and an extraction electrode system 10, which is extracted from The plasma 6 in the plasma generating unit 4 extracts an ion beam 20 .

[0040] In this example, the plasma generation unit 4 emits thermal electrons from a filament 8 provided in the plasma generation container 5, and causes a discharge (arc discharge) between the filament 8 and the plasma generation container 5 also serving as an anode, The ionizable gas 38 is ionized to generate a plasma 6 . The filament 8 is connected with a filament power supply 50 for heating it, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com