Single-layer hydrotalcite nano material and application thereof in efficient mineralization removal of high-concentration heavy metal ions in wastewater

A technology of heavy metal ions and nano-materials, which is applied in the field of mineralization treatment, can solve the problems of large consumption and weak stability, and achieve the effects of high-efficiency removal, large specific surface area, and improved adsorption rate and capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

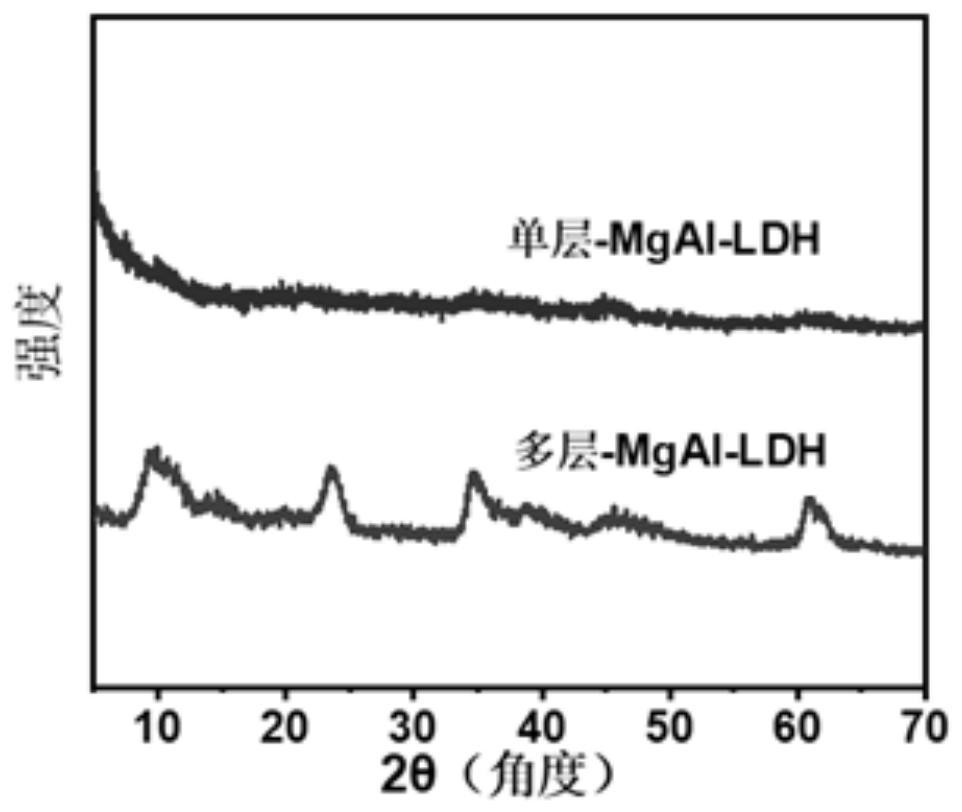

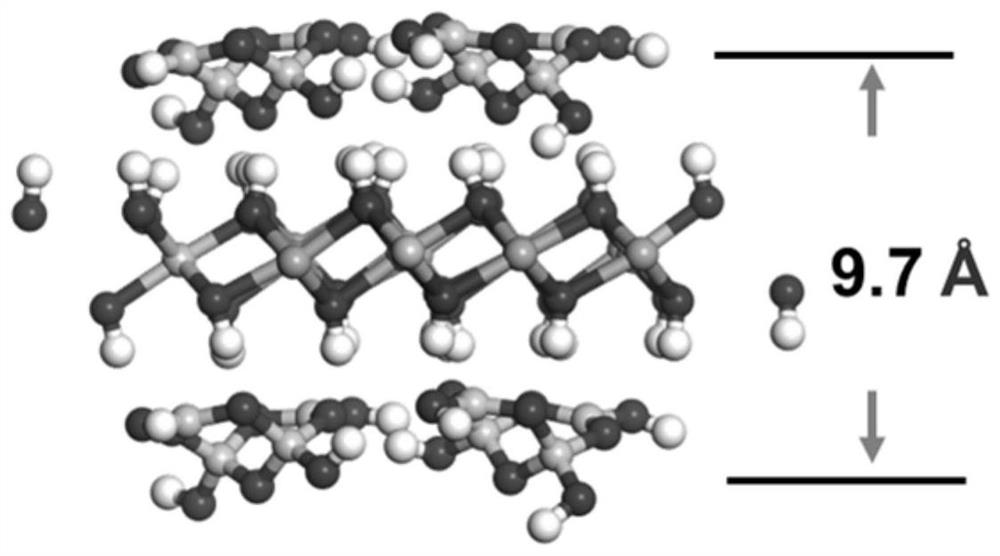

[0039] 1. Preparation of single-layer MgAl-LDH nanomaterials:

[0040] 0.01875mol Mg(NO 3 ) 2 ·6H 2 O, 0.00625mol Al(NO 3 ) 3 9H 2 O plus 0.0.0625 molH 3 BO 3 Dissolve in 100mL to remove CO 2 water and recorded as solution A. 0.075mol NaOH dissolved in 100 mL to remove CO 2 water and recorded as solution B. where the excess base is used to neutralize the H 3 BO 3 Excess H carried + . Solution A and solution B were simultaneously and uniformly poured into a fully back-mixed rotary liquid film reactor with a rotating speed of 3000 rpm and back-mixed for 2 minutes to obtain a suspension.

[0041] Preparation of single-layer hydrotalcite peeling: the product after centrifugation of the suspension is peeled with acetone, and finally washed with ethanol until neutral, and then placed in a vacuum oven for drying.

[0042] Preparation of multilayer hydrotalcite: centrifuge the suspension, wash with deionized water, and dry in a vacuum oven.

[0043]2. Prepare the solut...

Embodiment 2

[0048] Preparation of single-layer NiFe-LDH material:

[0049] 0.01875mol Ni(NO 3 ) 2 ·6H 2 O, 0.00625mol Fe(NO 3 ) 3 9H 2 O plus 0.0.0625mol H 3 BO 3 Dissolve in 100mL to remove CO 2 water and recorded as solution A. Dissolve 0.075mol NaOH in 100mL to remove CO 2 water and recorded as solution B. where the excess base is used to neutralize the H 3 BO 3 Excess H carried + . Solution A and solution B were poured into a colloid mill with a rotating speed of 3000 rpm at a constant speed and mixed for 2 minutes to obtain a suspension.

[0050] Preparation of single-layer hydrotalcite peeling: the product after centrifugation of the suspension is peeled with acetone, and finally washed with ethanol to neutrality, then vacuum rotary evaporated and dried.

[0051] Preparation of multi-layer hydrotalcite: centrifuge the suspension, wash with deionized water, and dry by vacuum rotary evaporation.

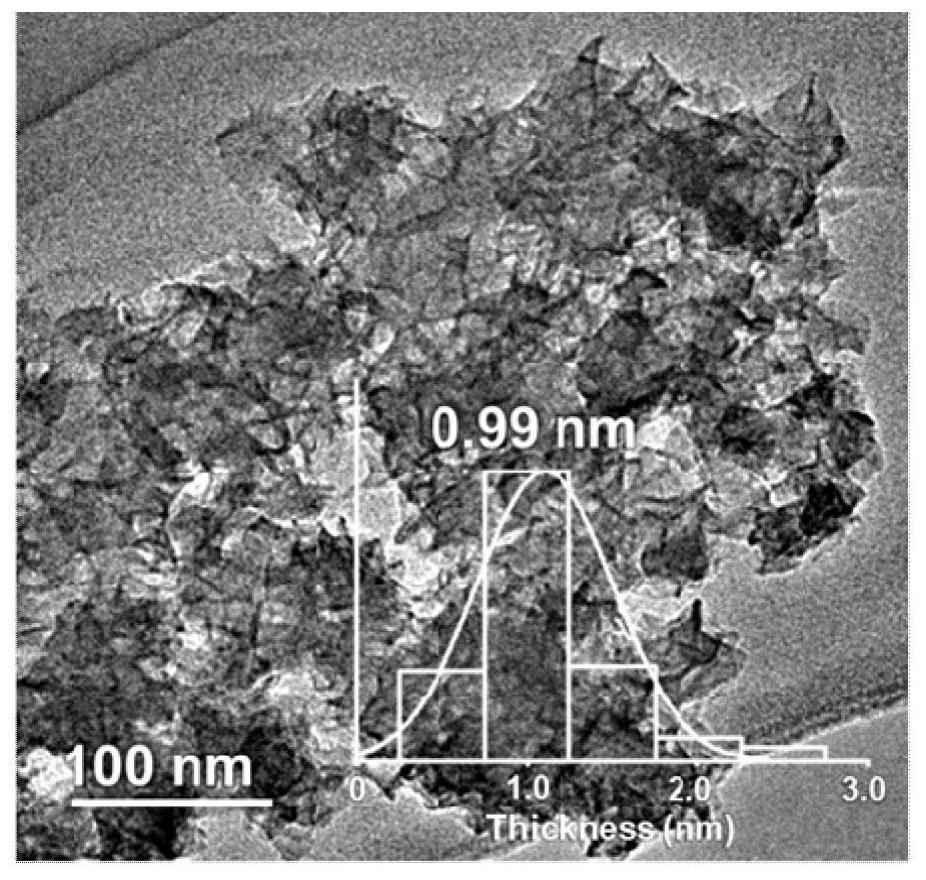

[0052] To characterize the material: e.g. Image 6 As shown, there is n...

Embodiment 3

[0054] Preparation of monolayer CoFe-LDH material:

[0055] 0.01875mol Co(NO 3 ) 2 ·6H 2 O, 0.00625mol Fe(NO 3 ) 3 9H 2 O plus 0.0.0625mol H 3 BO 3 Dissolve in 100mL to remove CO 2 water and recorded as solution A. Dissolve 0.075mol NaOH in 100mL to remove CO 2 water and recorded as solution B. where the excess base is used to neutralize the H 3 BO 3 Excess H carried + . Solution A and solution B were poured into a colloid mill with a rotating speed of 3000 rpm at a constant speed and mixed for 2 minutes to obtain a suspension.

[0056] Preparation of single-layer hydrotalcite peeling: the product after centrifugation of the suspension is peeled with acetone, and finally washed with ethanol until neutral, and then placed in a vacuum oven for drying.

[0057] Preparation of multilayer hydrotalcite: centrifuge the suspension, wash with deionized water, and dry in a vacuum oven.

[0058] Characterize the material: according to Figure 9 As shown, the monolayer Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com