Iron scrap collecting device for semicircle bearing bush finely boring machine

A collection device and fine boring machine technology, which is applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of scattered iron filings, no collection device, inconvenient collection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

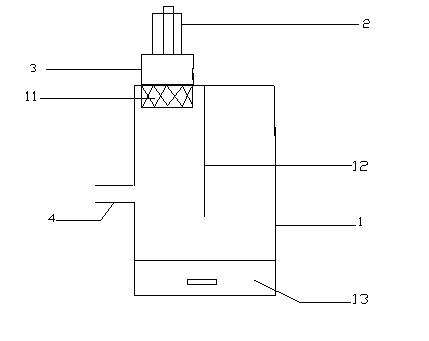

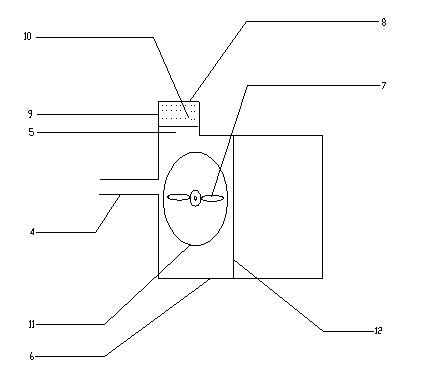

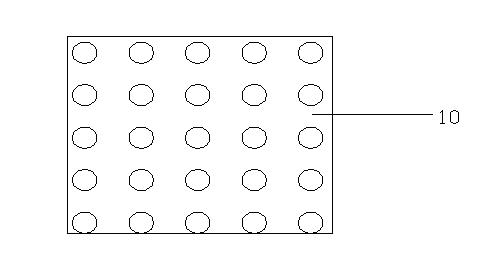

[0017] Implementation example figure 1 Shown includes a box body (1) and an exhaust fan device (3). Three adjacent side walls of the box body are successively provided with a chip inlet (4), an air outlet (5) and a box door (6). The air fan device includes a motor (2) and blades (7). The motor (2) is arranged on the outer top of the box (1). The motor shaft of the motor penetrates the box and connects with the blades on the top of the box. The chip inlet (4) ) Is lower than the blade (7), and the air outlet (5) is flush with the blade (7). A muffler (8) is provided outside the box of the air outlet (5). The muffler includes an outer cover (9) and a honeycomb muffler board (10). The outer cover (9) covers the air outlet (5). Outside the box body, a honeycomb muffler plate (10) is connected between the outer wall of the box body of the air outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com