Unilateral positioning method for secondary docking of ship in dock

A side positioning and ship technology, applied in the direction of berth, ship parts, ship construction, etc., can solve the problems of difficult to guarantee positioning accuracy, asymmetric cable length, low safety factor, etc., to improve positioning accuracy, improve the scope of application, and ease the use of The effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The unilateral positioning method of the secondary falling pier of the ship in the dock is realized through the following steps:

[0047] 1) Inject water into the dock to make the undocked ship undock;

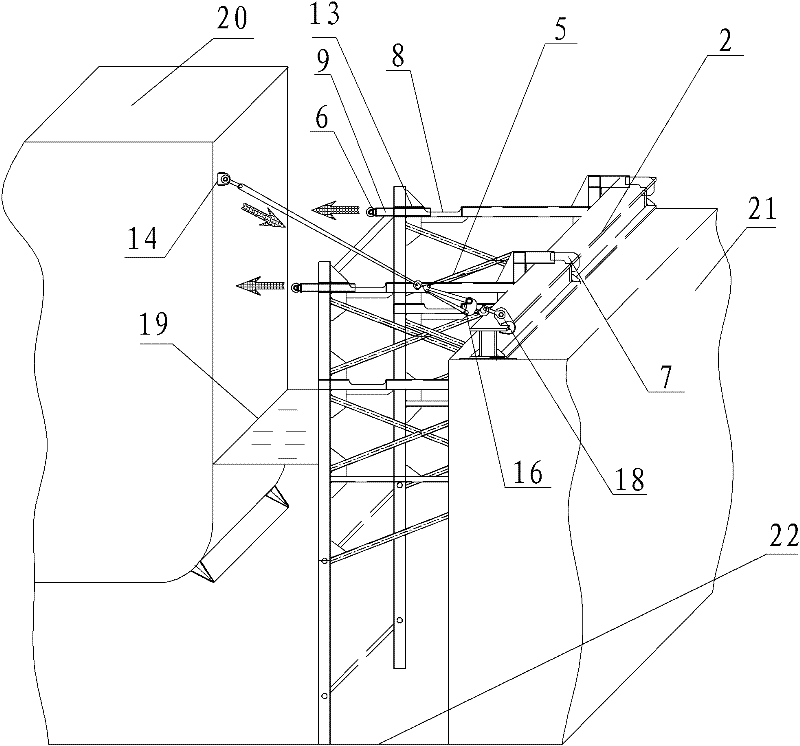

[0048] 2) When the ship that needs to be lowered for the second time meets the safe floating state, the ship that needs to be lowered for the second time is towed to the predetermined position near the side of the dock by the dockside pilot car and the vertical winch;

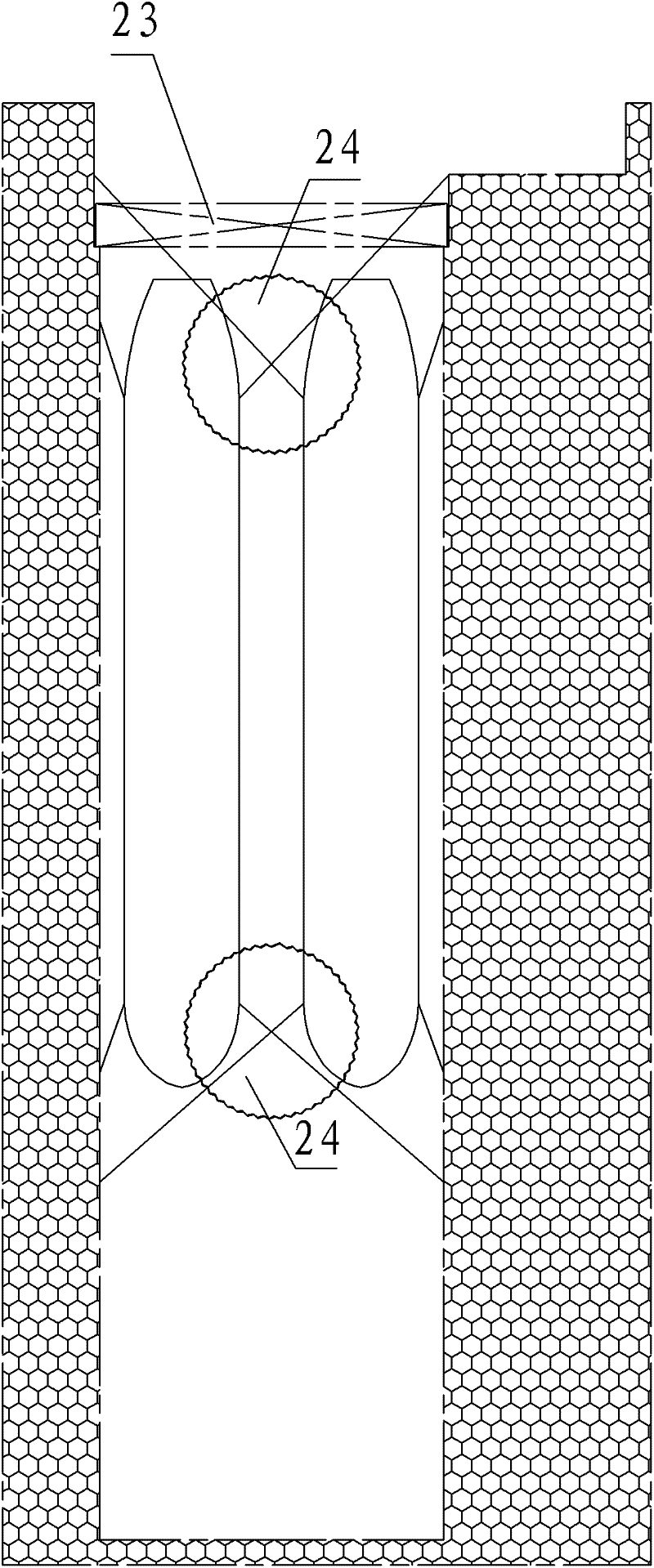

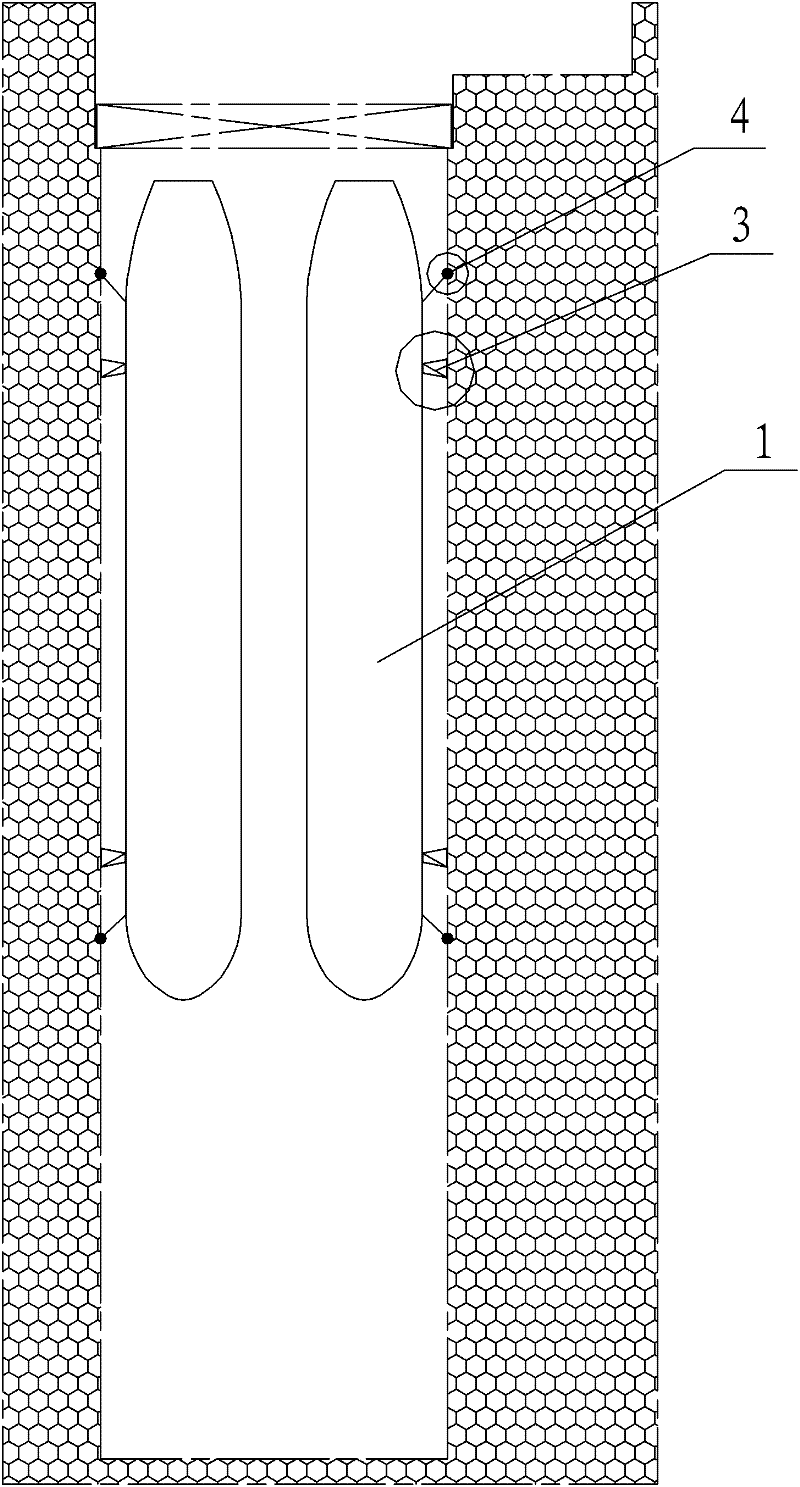

[0049] 3) A limit device 3 is arranged in the dock, the limit device 3 is installed on the bottom of the dock and fixedly connected with the inner wall of the dock wall, and is used to limit the position of the ship; and a retracting device 4 is arranged, and the retracting device is connected to the ship and the dock wall , used to tow and gather ships.

[0050] 4) Set up measuring instruments on the dock wall to measure and locate the ship that needs to be dropped twice, record and report the directio...

Embodiment 2

[0056] The unilateral positioning method of the secondary falling pier of the ship in the dock is realized through the following steps:

[0057] 1) Inject water into the dock to make the undocked ship undock;

[0058] 2) if figure 2 As shown, when the ship that needs to be dropped on the pier meets the safe floating state, that is, after the water level in the dock is greater than the maximum floating draft of the bow and stern of the hull by more than 500mm, the ship that needs to be towed by the dockside trolley and the vertical winch to the predetermined position near the side of the dock;

[0059] 3) A limit device 3 is arranged in the dock, the limit device 3 is installed on the bottom of the dock and fixedly connected with the inner wall of the dock wall, and is used to limit the position of the ship; and a retracting device 4 is arranged, and the retracting device is connected to the ship and the dock wall , used to tow and gather ships. The dock wall top is also pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com