Miniature semi-active folding flapping wing

A semi-active and miniature technology, applied in the field of folding flapping wings, can solve the problems of increasing the complexity and weight of the flapping wing drive mechanism, reducing the reliability of the flapping wing driving mechanism, increasing the weight and moment of inertia of the wing, and achieving low weight cost. , Efficiency improvement, the effect of improving aerodynamic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

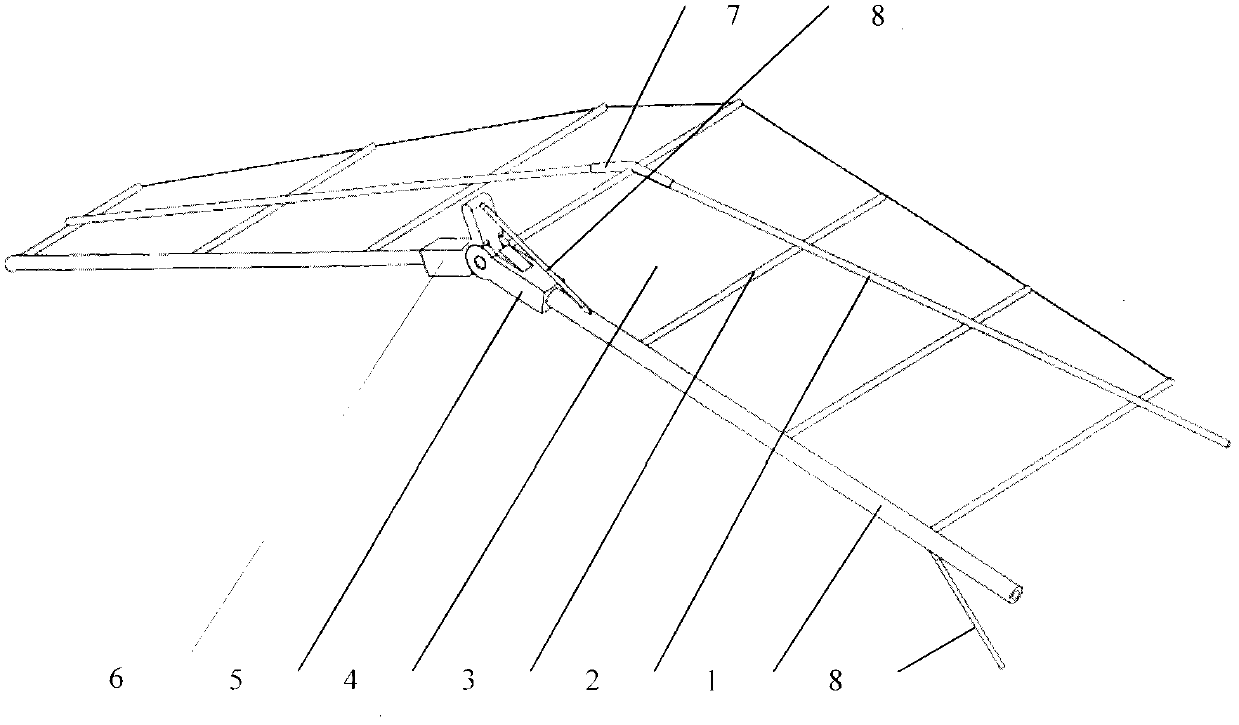

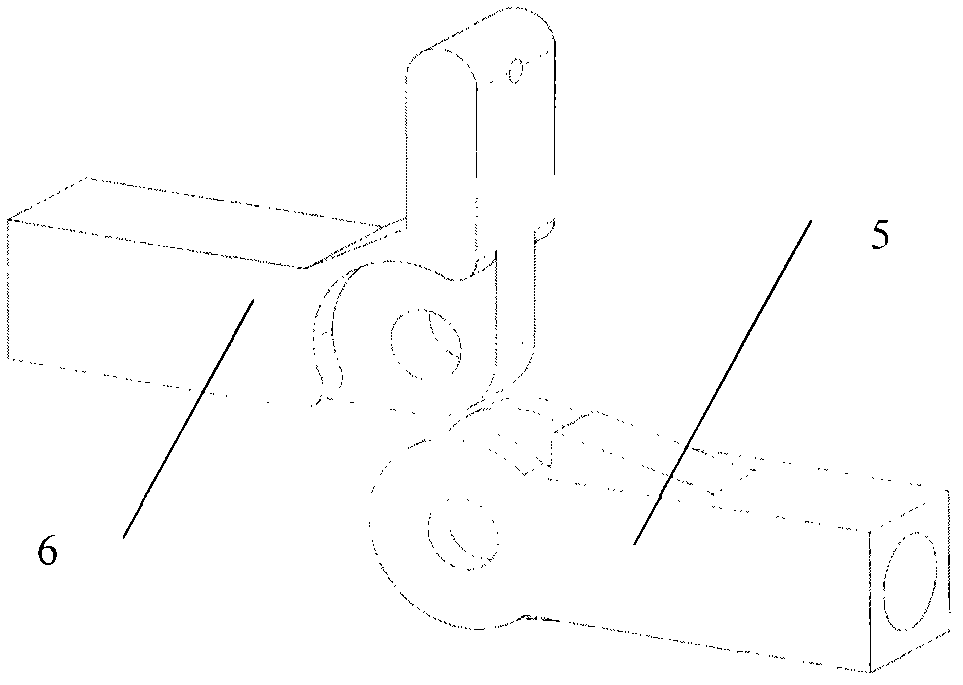

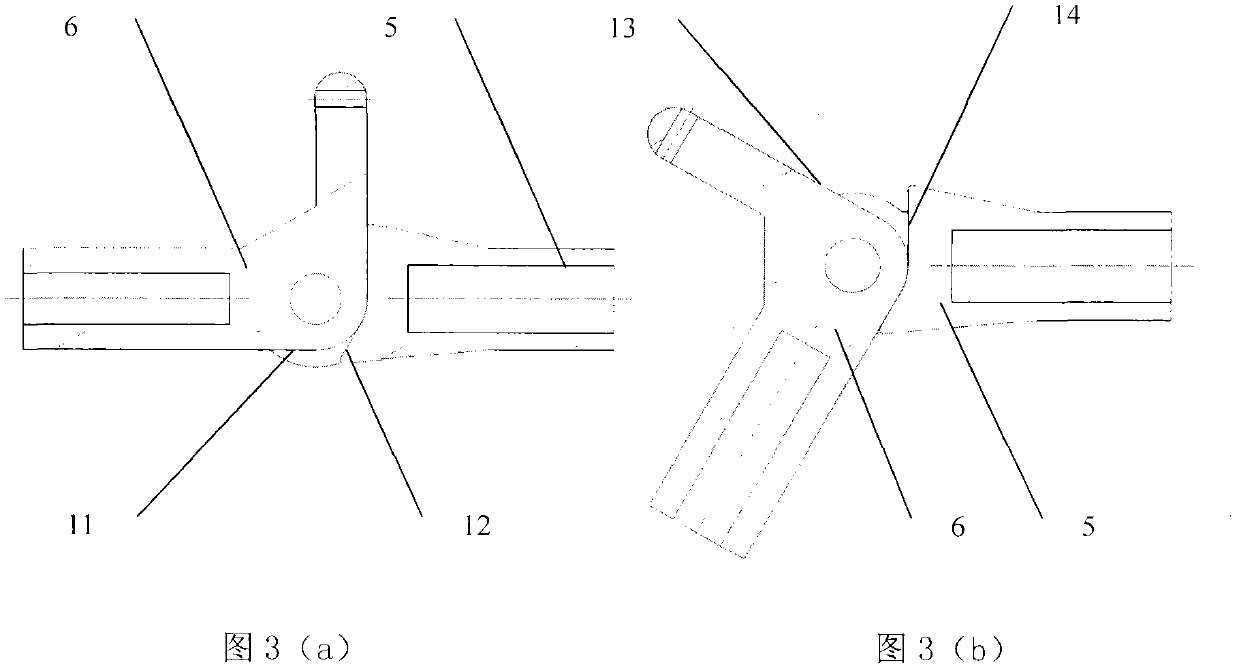

[0026] The miniature semi-active folding flapping wing of the present invention is composed of a front beam 1, a slanting beam 2, a wing rib 3, and a skin 4. The material of the front beam, the slanting beam and the wing rib is a resin-based carbon fiber composite material, and the skin is a puncture-resistant polyether film.

[0027] The front spar is parallel to the span direction and is located at the leading edge of the flapping wing; the oblique spar is located chordwise behind the front spar at an acute angle to the span direction, and its endpoint at the wing tip is closer to the flapping wing than its endpoint at the wing root leading edge. The front beam and the inclined beam are divided into two sections in the middle of the wingspan direction. The inner section 1A of the front beam is hollow and is fixedly connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com