Recycling process for printing and dyeing waste water

A printing and dyeing wastewater and process technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as environmental pollution, polluted environment, and failure to recycle and reuse wastewater , to achieve the effect of good treatment effect and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

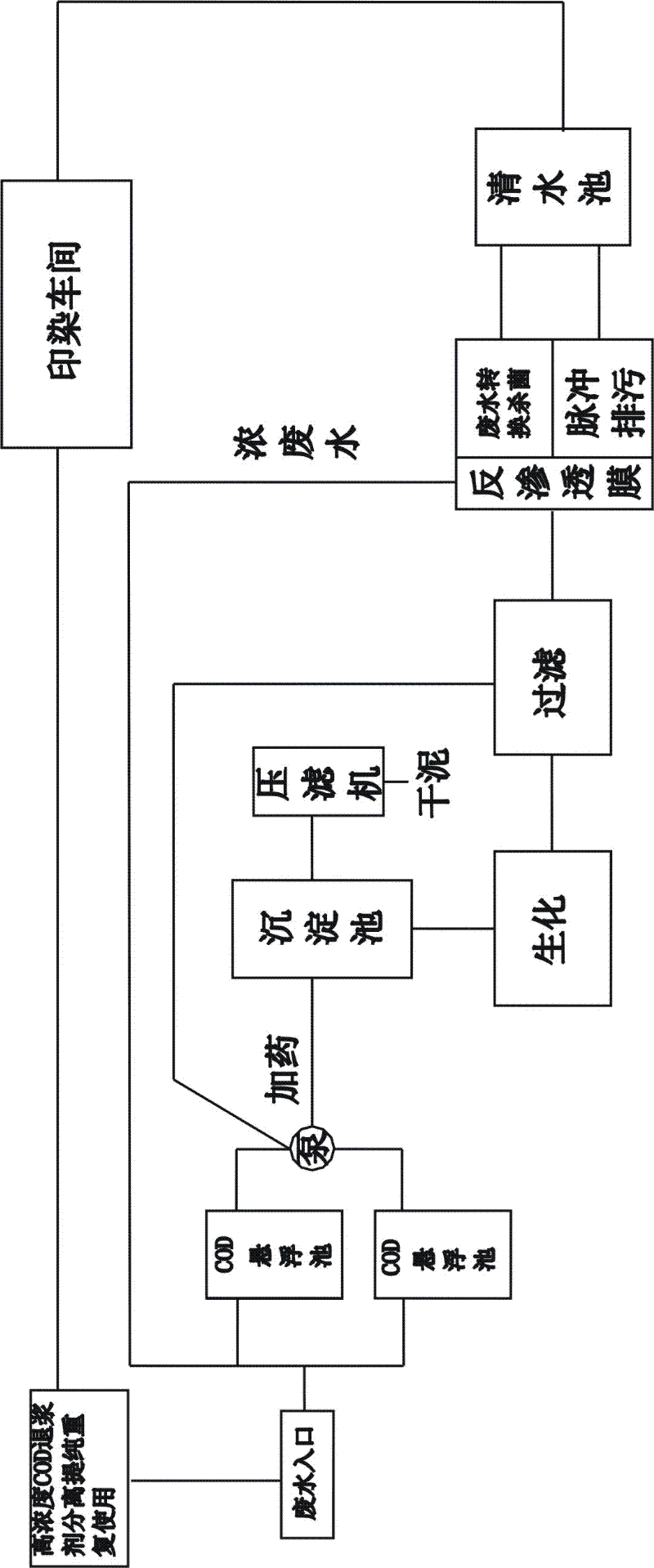

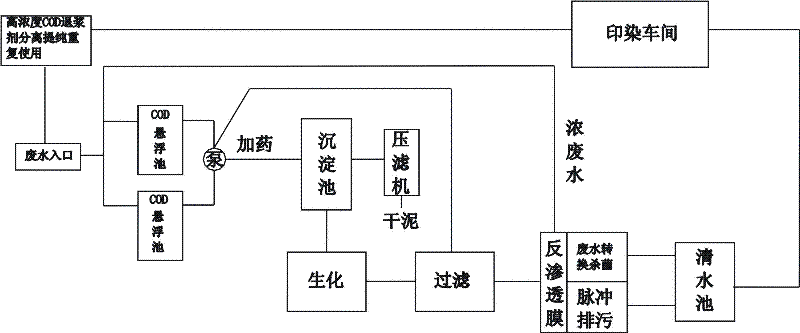

[0022] Embodiment 1: As an embodiment of the printing and dyeing wastewater recycling process of the present invention, such as figure 1 It includes the following steps: (1) Suspension removal of COD in the wastewater in the suspension tank to reduce the COD concentration; (2) Press out the sludge in the wastewater through a filter press; (3) Treat the wastewater in the biochemical tank Wastewater is biochemically treated to reduce COD concentration; (4) Wastewater is filtered through a filter device, separated, and discharged into a clear water pool for recycling.

[0023] In this embodiment, the step (1) first adjusts the pH value of the waste water to 7.5 by adding soda ash, then presses air into the waste water in the suspension tank to turn the waste water up and down for aeration, and finally adds water to the waste water in the sedimentation tank. The drug is precipitated.

[0024] In this embodiment, the filtering device in the step (4) includes a security filter, a r...

Embodiment 2

[0026] Embodiment 2: As an embodiment of the printing and dyeing wastewater recycling process of the present invention, the difference from Embodiment 1 is that before the step (1), the high-concentration wastewater discharged from the printing and dyeing workshop is set to produce acid analysis after adjusting the pH value. The step (a) of reducing the COD concentration and separating and extracting the desizing agent; the COD value of the high-concentration wastewater in the step (a) is 22400, and the pH value is 12.79; the pH value of the wastewater is adjusted by adding sulfuric acid in the step (a) value to 1.8, at this time the COD value of the wastewater is 4640; the step (1) first adjusts the pH value of the wastewater to neutral by adding soda ash, and then presses air into the wastewater in the suspension tank to turn the wastewater up and down for aeration , and finally add medicine to the wastewater in the sedimentation tank for precipitation; the printing and dyein...

Embodiment 3

[0028] Embodiment 3: As an embodiment of the printing and dyeing wastewater recycling process of the present invention, the difference from Embodiment 2 is that: the COD of the wastewater is 24000, and the pH value is 13.5; in the step (a), the wastewater is adjusted by adding sulfuric acid The pH value of the wastewater reaches 2.1, and the COD value of the wastewater is 5040 at this time; the step (1) first adjusts the pH value of the wastewater to neutrality by adding soda ash; the printing and dyeing wastewater recycling process also includes directly using The waste water in between washes the reverse osmosis membrane and destroys the living conditions of bacteria.

[0029] In this embodiment, other steps and parameters are consistent with those in Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com