Environment-friendly trivalent chromium electroplating solution and environment-friendly trivalent chromium electroplating method thereof

A technology of trivalent chromium and electroplating solution, which is applied in the field of electroplating technology, can solve the problems of poor corrosion resistance of the coating, low coverage of the plating solution, and inability to meet the needs of industrial production, and achieve the effect of improving corrosion resistance and coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

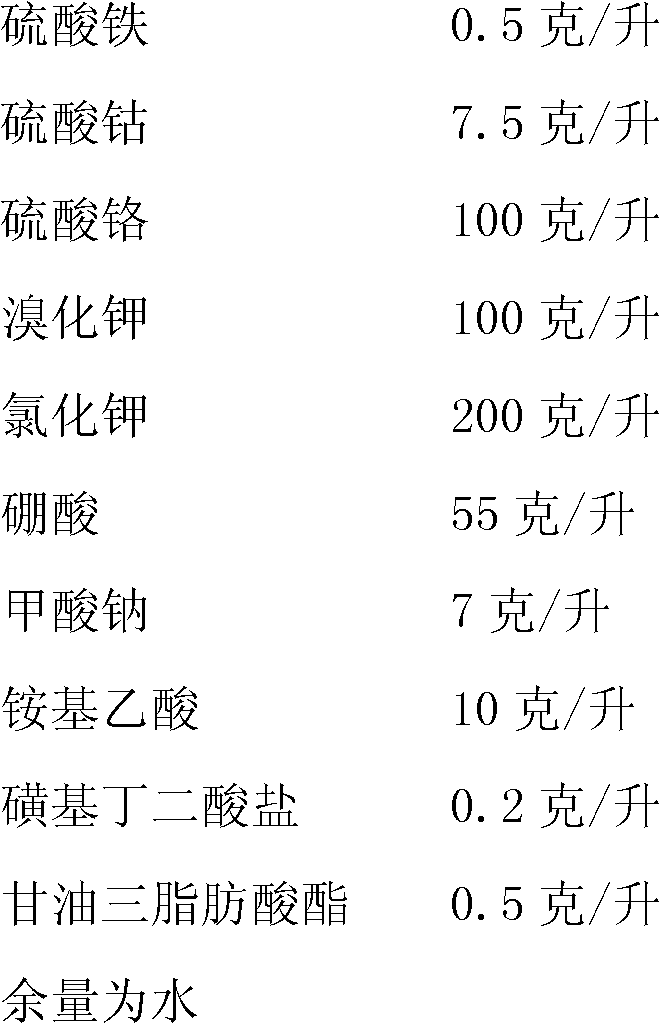

[0027] Plating solution composition:

[0028]

[0029] Electroplating method: take a nickel-plated sheet (standard brass sheet 100*70 mm with a nickel layer thickness of 8 microns), and conduct an electroplating test in a 267ml Hou's bath. The conditions are: temperature 35 ° C, DC current 8 amps, electroplating 2 Minutes, high-purity graphite (purity 99.99%) was used as the anode to obtain test piece A1.

[0030] Evaluation of electroplating effect: Observe the bright area on the test piece with a range of 5×9.4 cm, and the current density range of the plating solution can be obtained, and then the covering ability of the plating solution can be evaluated. Seal the parts not coated with chromium layer with varnish, and do neutral salt spray test for 36 hours, no chromium layer corrosion is found.

Embodiment 2

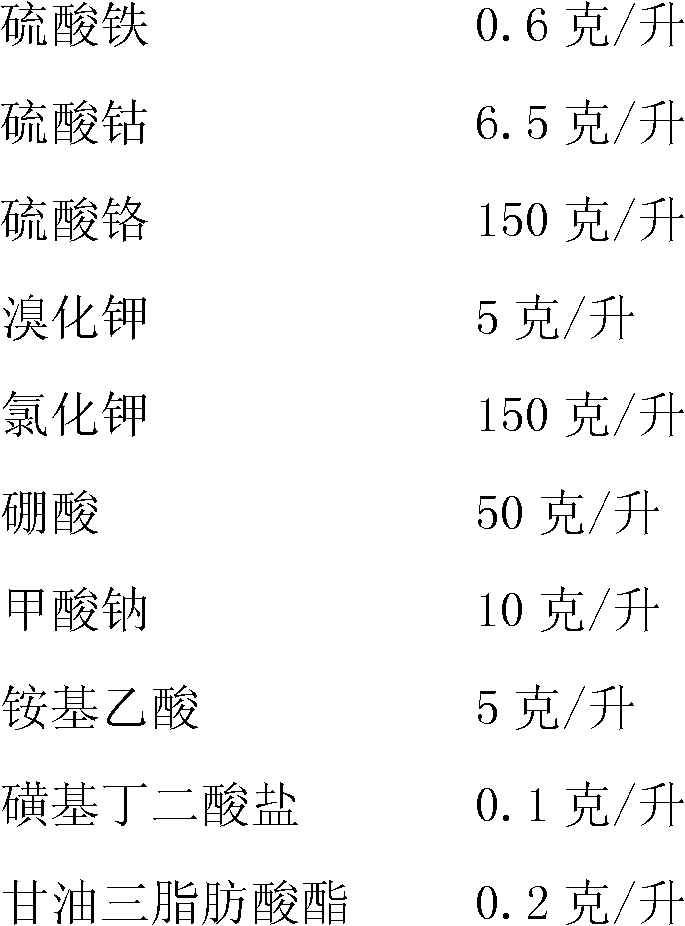

[0032] Plating solution composition:

[0033]

[0034]

[0035] Electroplating method: take a nickel-plated sheet (standard brass sheet 100*70 mm with a nickel layer thickness of 8 microns), and conduct an electroplating test in a 267ml Hou's bath. The conditions are: temperature 35 ° C, DC current 8 amps, electroplating 2 Minutes, high-purity graphite (purity 99.99%) was used as the anode to obtain test piece A2.

[0036] Evaluation of electroplating effect: Observe the bright area on the test piece with a range of 5×9.5 cm, and the current density range of the plating solution can be obtained, and then the covering ability of the plating solution can be evaluated. Seal the parts not coated with chromium layer with varnish, and do neutral salt spray test for 32 hours, no chromium layer corrosion is found.

Embodiment 3

[0038] Plating solution composition:

[0039]

[0040] Electroplating method: take a nickel-plated sheet (standard brass sheet 100*70 mm with a nickel layer thickness of 8 microns), and conduct an electroplating test in a 267ml Hou's bath. The conditions are: temperature 35 ° C, DC current 8 amps, electroplating 2 Minutes, high-purity graphite (purity 99.99%) was used as the anode to obtain test piece A3.

[0041] Evaluation of electroplating effect: Observe the bright area on the test piece with a range of 5×9.1 cm, and the current density range of the plating solution can be obtained, and then the covering ability of the plating solution can be evaluated. Seal the parts not coated with chromium layer with varnish, and do neutral salt spray test for 32 hours, no chromium layer corrosion is found.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com