Receiving system of digital sizing machine

A sizing machine and digital technology, applied in the field of digital printing machines, can solve problems affecting fabric quality, low efficiency, big belly, etc., and achieve the effects of manpower saving, flexible use, and high speed

Inactive Publication Date: 2013-08-07

无锡市德赛数码科技有限公司

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, when sizing traditional digital printing machines, multiple separate devices are used to complete the sizing. Usually at least three devices are required for sizing, heating, and widening and winding, which is inefficient, especially when expanding and winding. , it is prone to tail slant and big belly, which will seriously affect the quality of fabrics

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

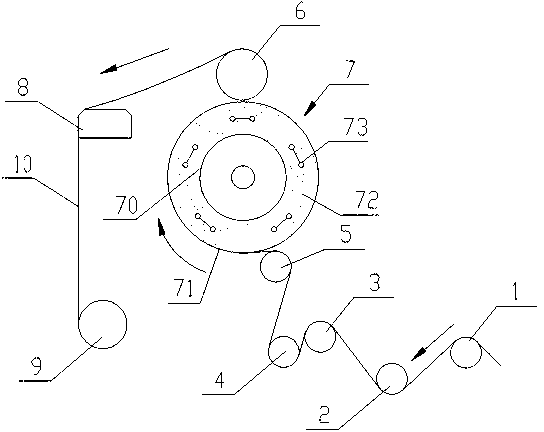

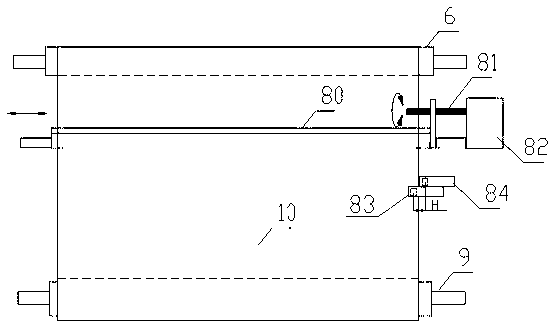

The invention discloses a receiving system of a digital sizing machine, comprising a cloth discharging roll (1). The receiving system is characterized in that one side of the cloth discharging roll (1) is provided with an expanding roll (3); one side of the expanding roll (3) is provided with a roller-type heat-conducting oil heating device (7); a pressing roll (6) is arranged above the roller-type heat-conducting oil heating device (7); the outer side of the roller-type heat-conducting oil heating device (7) is provided with an automatic correcting device (8); and an automatic tension winding roll (9) is arranged below the automatic correcting device (8). In the receiving system, four procedures such as the heating, expanding, automatic correction and winding are integrated, and the automatic computer control is wholly realized; and the defects for simultaneous use of more equipment in the prior art are overcome. In the receiving system, the heating of the roller-type heat-conductingoil heating device is uniform and stable, the temperature is easy to control, the roller-type heat-conducting oil heating device and the pressing roll are matched for acting on the cloth together, sothat good use effect is achieved. In the receiving system, the sizing of a sizing system is more uniform than the original type, the speed is fast, the sizing effect is very obvious and the effect after printing can be improved.

Description

technical field [0001] The invention relates to the field of digital printing machines, in particular to a digital sizing machine receiving system used in the sizing process before cloth printing. Background technique [0002] Digital printing machine is also known as universal flatbed printer. The curved surface printer universal flatbed printer can print any material and irregular soft and hard objects, such as: metal, ceramics, crystal, glass, acrylic, stone, PVC, plastic, toys, U disk, cloth, wood, silicone, Leather, etc., digital printers can reduce costs, reduce labor, and improve efficiency for you, because digital printers do not need to produce film plates, full-color one-shot imaging, accurate positioning, and zero scrap rate. The high-tech products of Longjie digital printers completely replace the traditional crafts such as screen printing, pad printing and transfer printing. They are environmentally friendly products and can be exported. It is the trend of spe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D06C27/00

Inventor 岳双君

Owner 无锡市德赛数码科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com