Water surface oil recovering device

A technology for collecting oil tanks and oil tankers, which is applied to the cleaning of open water surfaces, water conservancy projects, and general water supply conservation. It can solve the problems of low recovery efficiency of thin oil layers, recovery of emulsified oil and high-viscosity oil that are not easy to be scraped off, and achieve enhanced Deoiling effect, promoting flow, highlighting the effect of energy saving and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

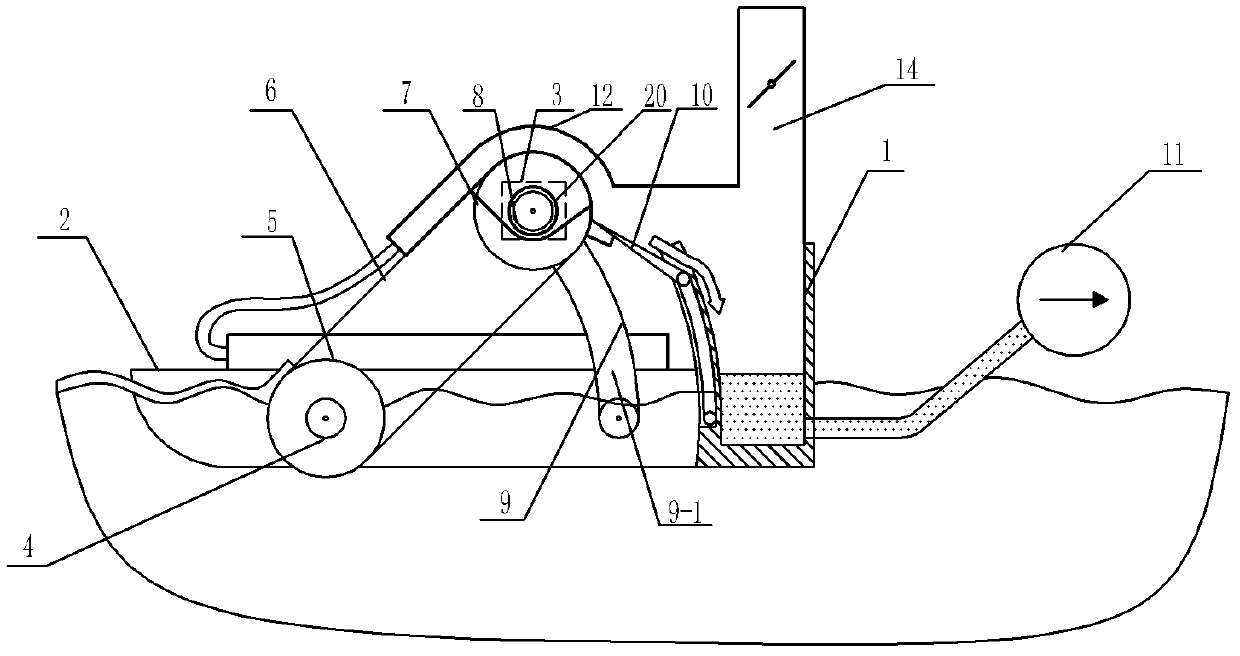

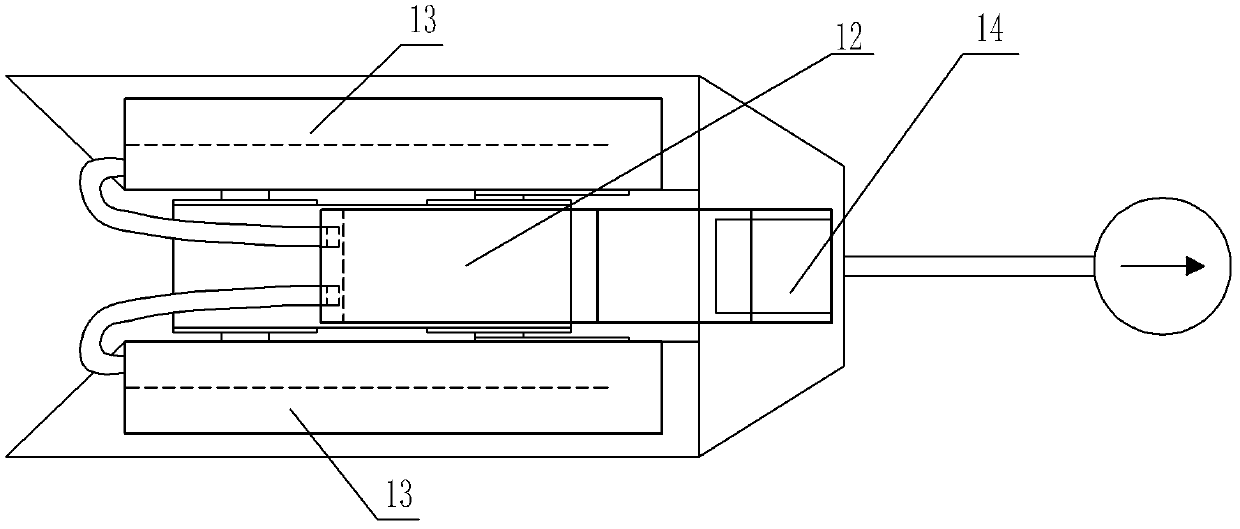

[0017] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, the device of this embodiment comprises oil receiving tank 1 and support frame 2, described device also comprises motor 3, oil suction wheel shaft 4, oil suction wheel 5, oil removal belt 6, deoiling wheel 7, deoiling wheel shaft 8, scraper Sheet 10, light-transmitting flow guide heat preservation cover 12, solar chimney 14, two angle adjustment brackets 9, two solar air heat collectors 13 and two shaft support seats 20, the oil collection tank 1 is fixed on the side wall of the support frame 2 On, two solar air heat collectors 13 are housed on the support frame 2, the deoiling wheel shaft 8 is contained on the two shaft support seats 20, the motor 3 is fixed on the shaft support seats 20, and the output shaft of the motor 3 can be connected with the deoiler The wheel shaft 8 is connected by transmission, and can also be pressed and contacted with the oil removal belt 6 through a...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 1 and figure 2 To illustrate this embodiment, the degreasing belt 6 of this embodiment is a flat belt, a toothed belt or a chain brush belt, and the degreasing belt is black or the surface is painted with a paint with strong radiation absorption capacity. Choose different types of oil removal belts according to the thickness of the oil layer and the characteristics of the oil. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

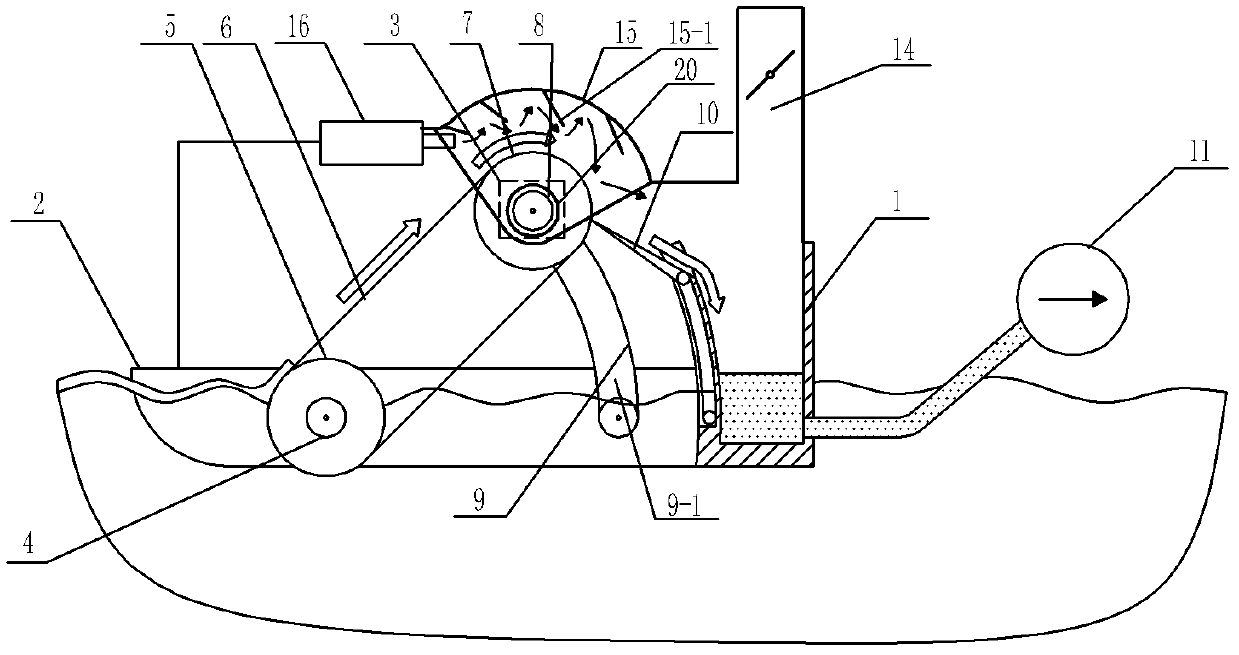

[0020] Specific implementation mode three: combination image 3Describe this embodiment, the device of this embodiment comprises oil receiving tank 1 and support frame 2, described device also comprises motor 3, oil suction wheel shaft 4, oil suction wheel 5, oil removal belt 6, deoiling wheel 7, deoiling wheel shaft 8, scraper Sheet 10, exhaust chimney 14, light-transmitting flow guide heat preservation cover 15, guide vane 15-1, hot air blower 16, two angle adjustment brackets 9 and two shaft support seats 20, the oil collection tank 1 is fixed on the support frame 2 On the side wall of the motor 3, the output shaft of the motor 3 can be transmission-connected with the deoiling wheel shaft 8, and can also be pressed and contacted with the deoiling belt 6 through an independent wheel shaft to drive its movement. The deoiling wheel shaft 8 is installed on two shaft support seats 20 Above, the motor 3 is fixed on the shaft support seat 20, the oil removal wheel 7 is mounted on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com