Coaxial probe for wafer probe cards and spider using same

A coaxial probe and probe card technology, applied in the direction of single semiconductor device testing, measuring electricity, measuring devices, etc., can solve the problems of instability and short circuit of capacitive and inductive coupling test, and achieve the stability and avoidance of short circuit. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

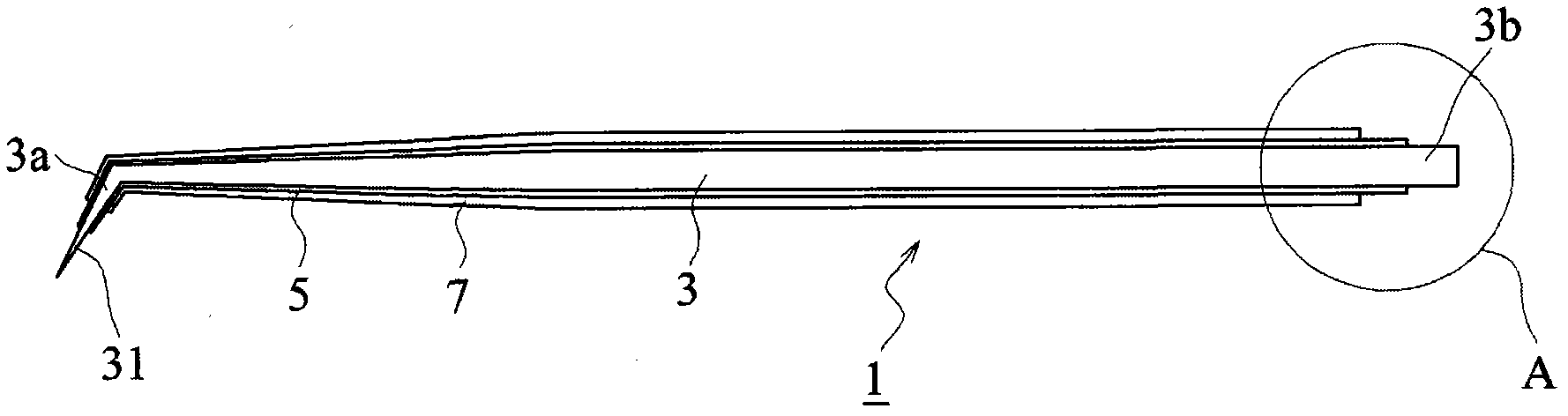

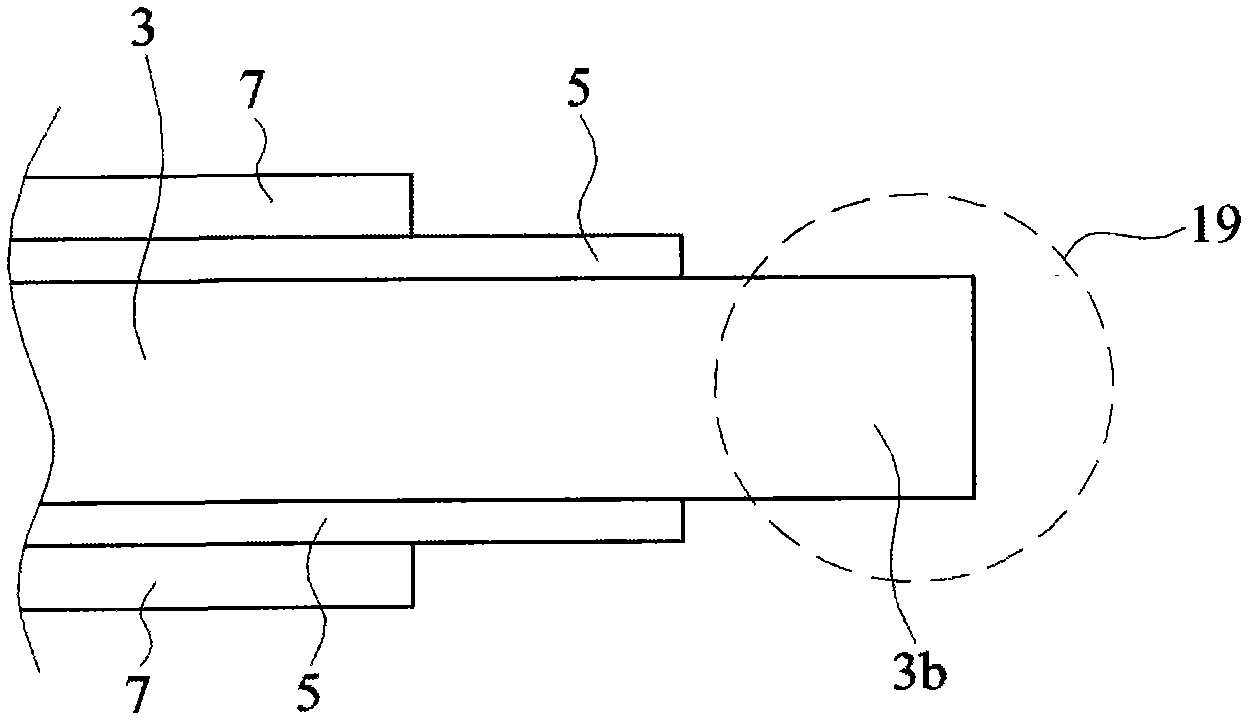

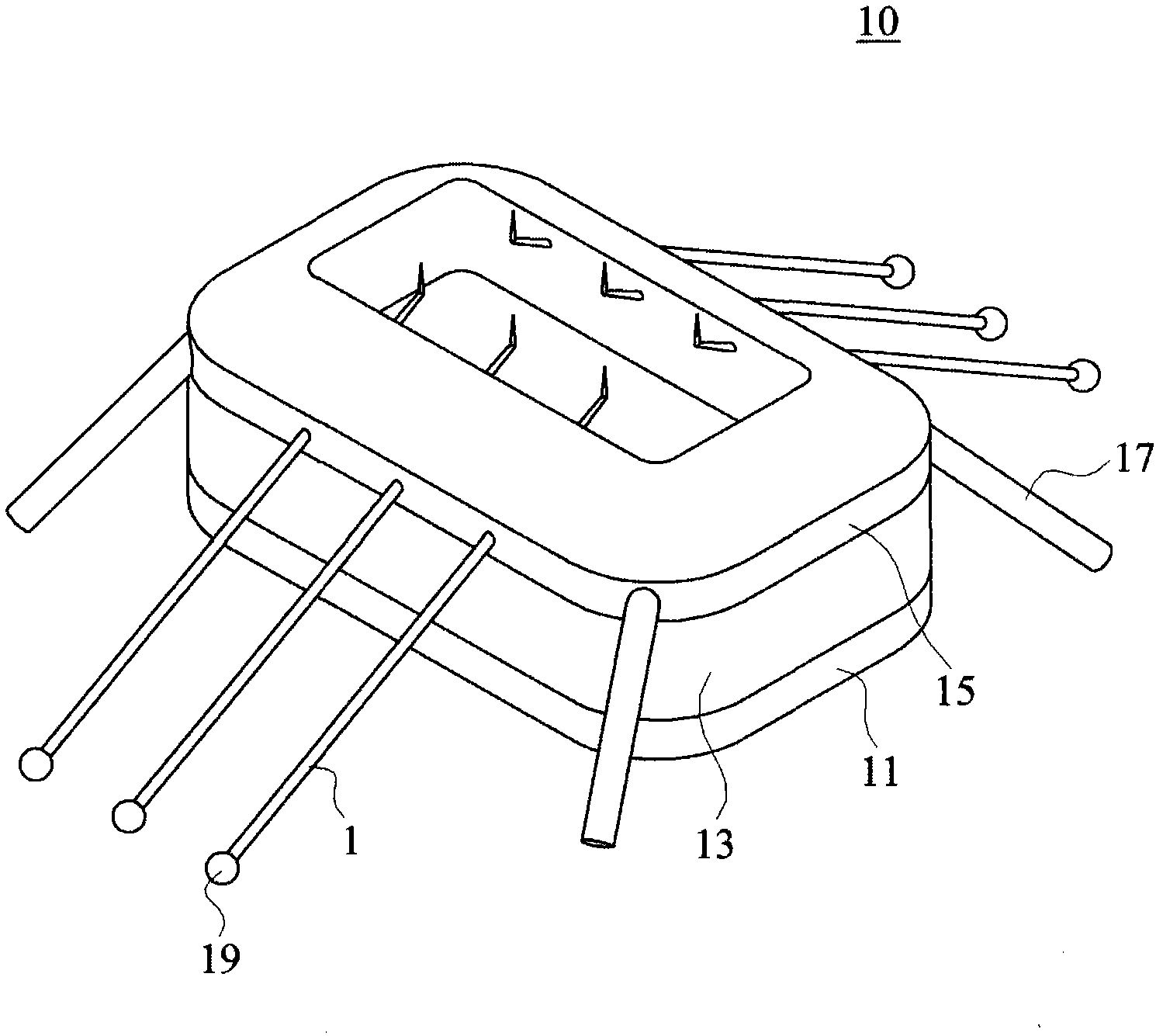

[0051] Figure 1A is a schematic cross-sectional view of a coaxial probe according to an embodiment of the present invention. Such as Figure 1A As shown, the coaxial probe 1 comprises: a tungsten or tungsten alloy probe body 3; one or more layers of insulating layer 5 deposited on a region of the probe body 3; and a metal conductive layer 7 deposited on at least a part of a Or multi-layer insulating layer 5. The probe body 3 has a first end 3 a and a second end 3 b, wherein the first end 3 a is inclined relative to the probe body 3 and has a tip 31 . Such as Figure 1A As shown, the area where one or more insulating layers 5 are deposited does not cover the tip 31 of the first end 3 a and the second end 3 b of the probe body 3 . The conductive metal layer 7 may be deposited to completely or partially cover the insulating layer 5 deposited on this area, ie, the conductive metal layer 7 may be deposited on at least a part of the insulating layer 5 . One or more insulating lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com