Stack type battery

A layered, layered electrode technology, used in secondary battery manufacturing, battery pack components, battery boxes/jackets, etc., can solve the problem of unconsidered positioning, time required, position misalignment, etc., to achieve easy and reliable. The effect of positioning, easy production and high precision production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

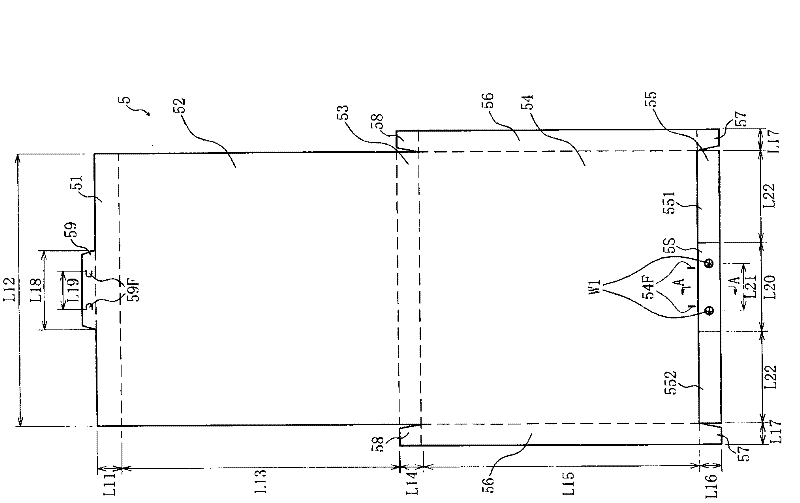

[0060] Hereinafter, the present invention will be described in more detail with reference to the drawings. However, the present invention is not limited to the following best mode at all, and can be appropriately changed and implemented within a range that does not change the gist of the present invention.

[0061] [making of positive electrode]

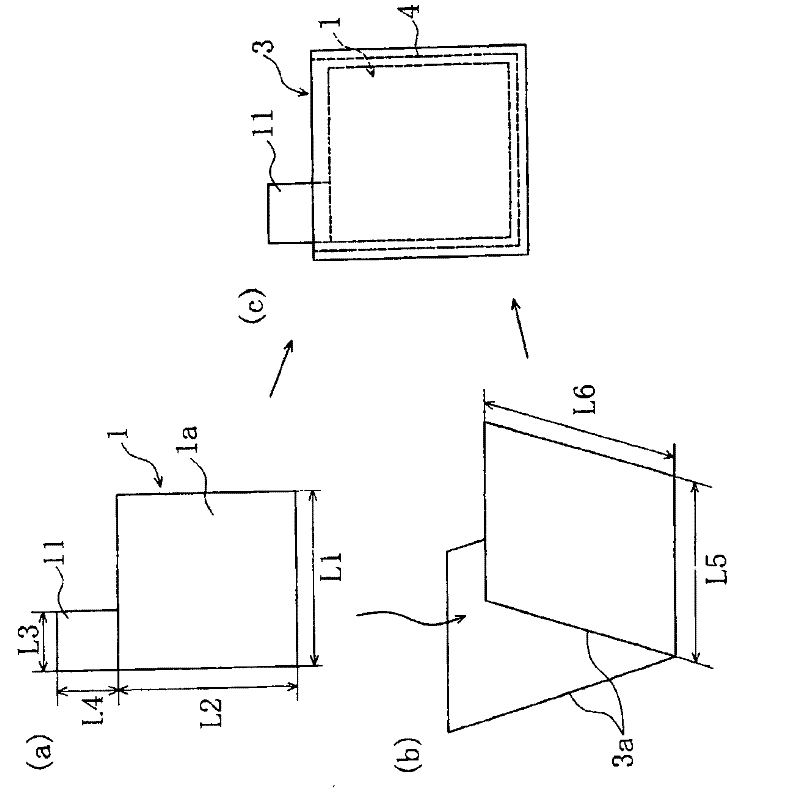

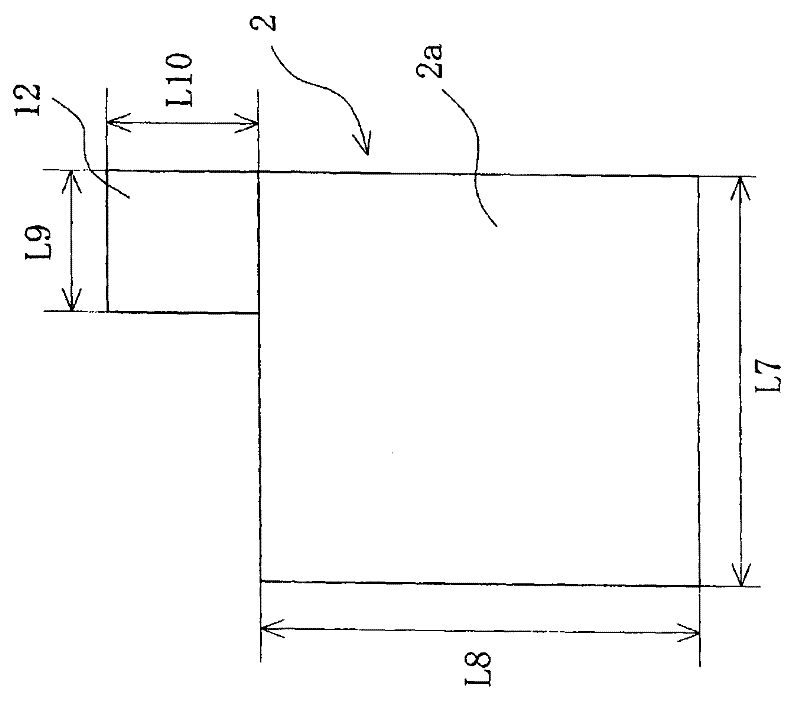

[0062] 90% by mass of LiCoO as the positive electrode active material 2 , 5% by mass of carbon black as a conductive agent, 5% by mass of polyvinylidene fluoride as a binder, and N-methyl-2-pyrrolidone (NMP) solution as a solvent were mixed to prepare a positive electrode slurry. Thereafter, this positive electrode slurry was coated on both surfaces of an aluminum foil (thickness: 15 μm) as a positive electrode current collector. After that, the solvent is removed by heating, and compressed with a roller until the thickness becomes 0.1mm, and then as figure 1 As shown in (a), the positive electrode plate 1 having the positive elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com