Heart valve prosthesis using different types of living tissue and method of fabricating the same

A technology of artificial heart valve and living tissue, applied in the direction of heart valve, medical science, stent, etc., can solve the problems of deformation or damage, loss of function, non-function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Reference will now be made in more detail to the preferred embodiment of the invention, an example of which is illustrated in the accompanying drawings.

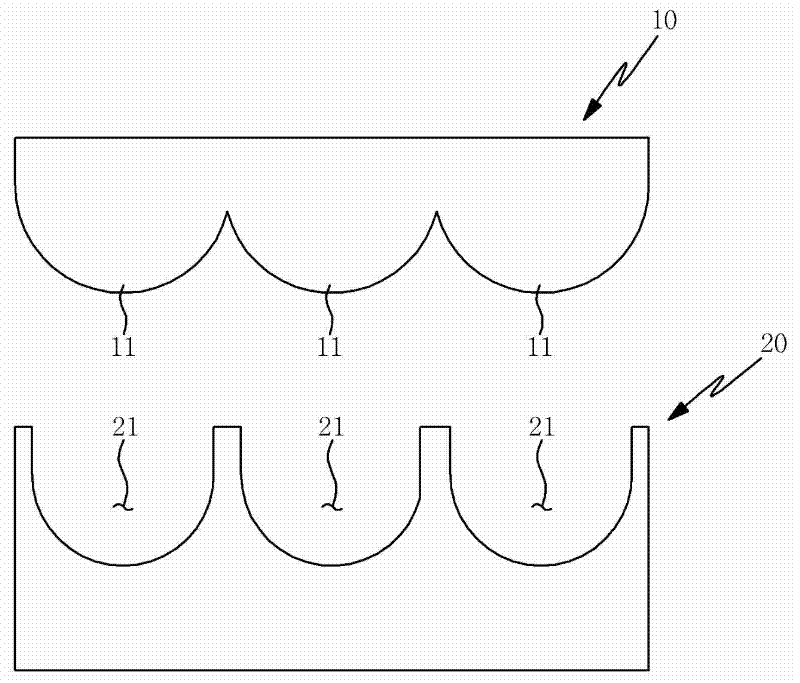

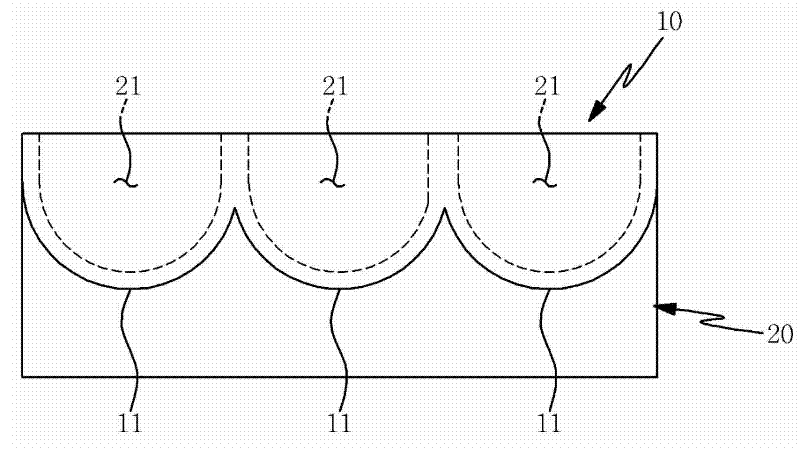

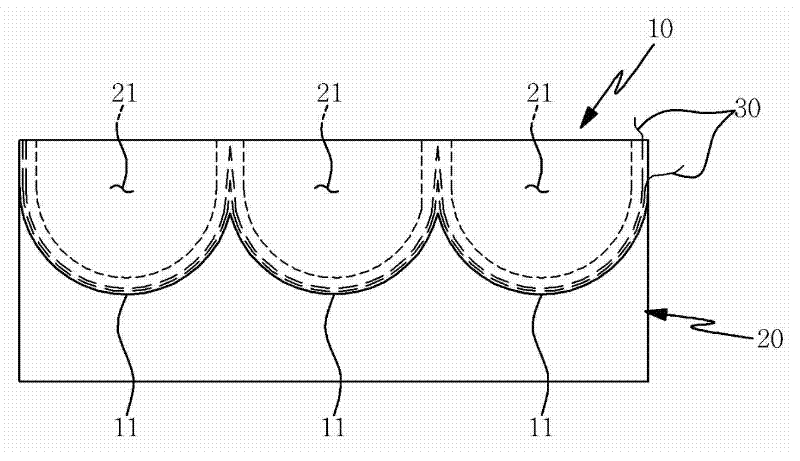

[0033] like Figure 1 to Figure 5 As shown in , according to an embodiment of the present invention, a method of using porcine pericardium to manufacture an artificial heart valve is by placing the valve body 10 on the polyester body 20, and using suture fibers 30 to suture the valve body 10 and the polyester body 20 , roll the polyester body 20 into a cylindrical shape to place the valve body 10 therein, suture the opposite sides of the polyester body 20 to each other using suture fibers, and insert the resulting structure into a stent braided using shape memory alloy wires 51 50, thereby making the artificial heart valve 100.

[0034] First, the valve body 10 was fabricated by taking out a rectangular leaflet from the porcine pericardium surrounding the porcine heart, and cutting the pericardium leaflet to form thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com