Compound grease microemulsion used in cosmetics and preparation method thereof

A technology of complex oil and microemulsion, which is applied in the direction of cosmetic preparations, cosmetics, dressing preparations, etc., can solve problems such as difficult to apply transparent systems, instability, etc., restore and maintain natural elasticity, prevent drying and cracking, easy-to-prepare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

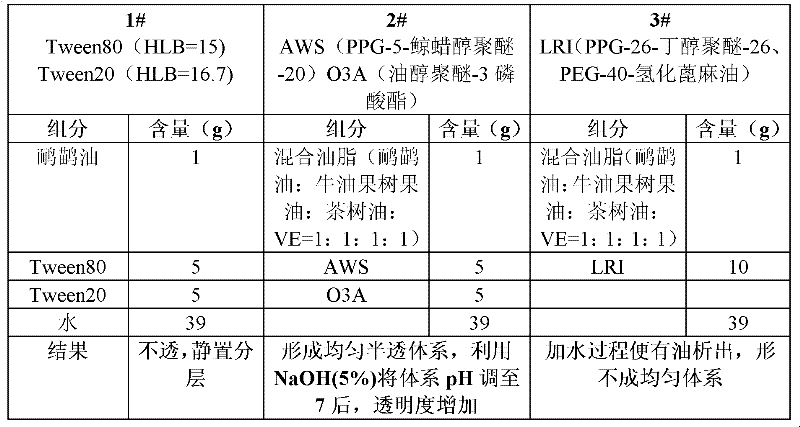

[0035] Embodiment 1, adopt surfactant, mixed oil and water of different proportions to prepare microemulsion

[0036] Using surfactant PPG-5-ceteth-20 (abbreviated as AWS) and oleth-3 phosphate (abbreviated as O3A), the mixing mass ratio of the two is 2:1;

[0037] The compound oil uses emu oil, avocado oil, tea tree oil and vitamin E, and the mixing mass ratio of the four is: 1.0:1.0:0.5:0.3;

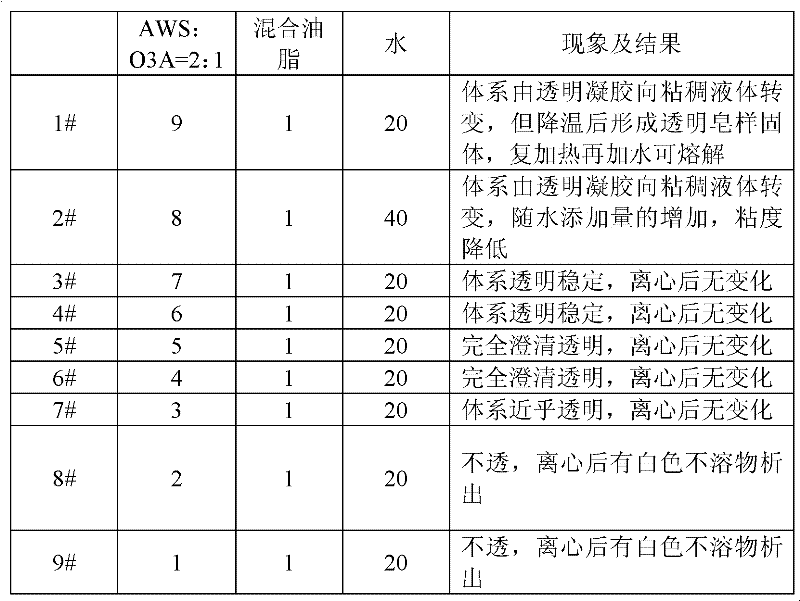

[0038] Take AWS+O3A as one phase; set the quality of the mixed grease as 1g, according to m(oil phase) / m(AWS+O3A)=1 / 9, 1 / 8, 1 / 7, 1 / 6, 1 / 5 , 1 / 4, 1 / 3, 1 / 2, 1 / 1 Calculate the quality of the surfactant, the amount of water added is the minimum amount for the system to be a uniform fluid, see the table below for details:

[0039]

[0040] Conclusion: According to the test results, when the ratio of AWS+O3A to mixed oil is greater than 3:1, a uniform transparent to translucent microemulsion system can be obtained by adjusting the amount of water added. The ratio of compound oil, surfac...

Embodiment 2

[0041] Embodiment 2: prepare compound grease microemulsion 1000g

[0042] 1) Weigh each component according to the following mass to prepare oil phase and water phase respectively, and prepare NaOH into 5% aqueous solution for later use:

[0043] Oil phase:

[0044] AWS

108g

O3A

54g

emu oil

10g

2g

1g

Vitamin E

20g

[0045] Water phase: water 761.8g

[0046] pH regulator: NaOH (5%) 43.2g

[0047] 2) Heat the water phase to 80°C and keep it warm; fully mix the components of the oil phase, and heat it to about 80°C in an 80°C water bath under nitrogen protection; under stirring at 300-500r / min, inject water into the oil In the phase mixture, continue to stir until the compound oil, surfactant, and water system are fully mixed to obtain a microemulsion.

[0048] 3) Cooling the above microemulsion to below 50° C., adding a pH regulator to adjust the pH to 6.8 to obtai...

Embodiment 3

[0051] Embodiment 3: prepare compound grease microemulsion 100g

[0052] 1) Weigh each component to prepare the oil phase and water phase according to the following mass, and prepare NaOH into a 5% aqueous solution for later use:

[0053] Oil phase:

[0054] AWS

10g

O3A

2g

emu oil

1.2g

2g

0.3g

Vitamin E

0.5g

[0055] Water phase: water 80.8g

[0056] pH regulator: NaOH (5%) 3.2g

[0057] 2) Heat the water phase to 75-80°C and keep it warm; fully mix the components of the oil phase, and heat it to 75-80°C in a water bath under nitrogen protection; under stirring at 300-500r / min, inject water into the oil In the phase mixture, continue to stir until the compound oil, surfactant, and water system are fully mixed to obtain a microemulsion.

[0058] 3) Cooling the microemulsion above to below 55° C., adding a pH regulator to adjust the pH to 6.8 to obtain the final mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com