Space robot orbit tool replacing device

A space robot and changer technology, applied in the direction of tools, manufacturing tools, manipulators, etc., can solve the problems of large pose tolerance, high quality, poor reliability of space operations, etc., to achieve the effect of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

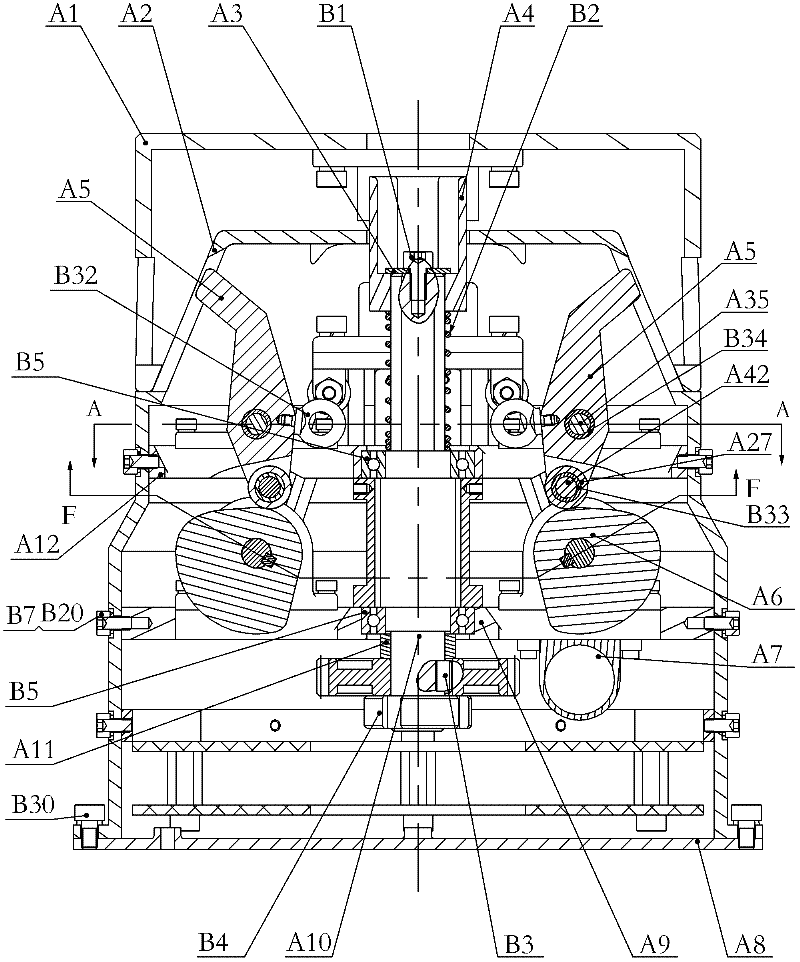

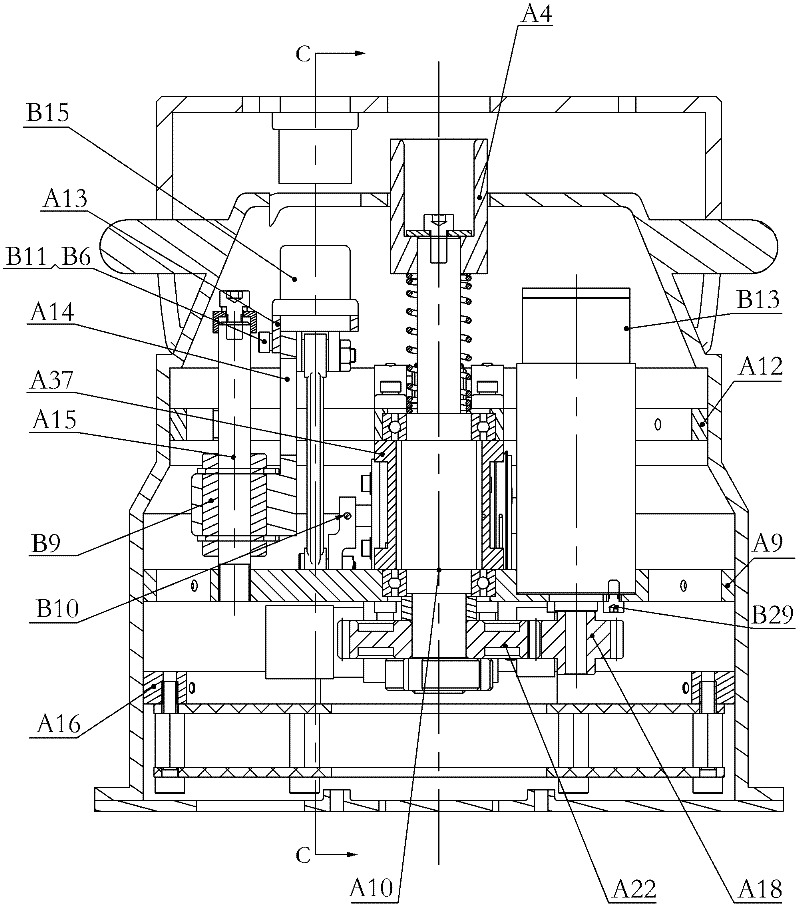

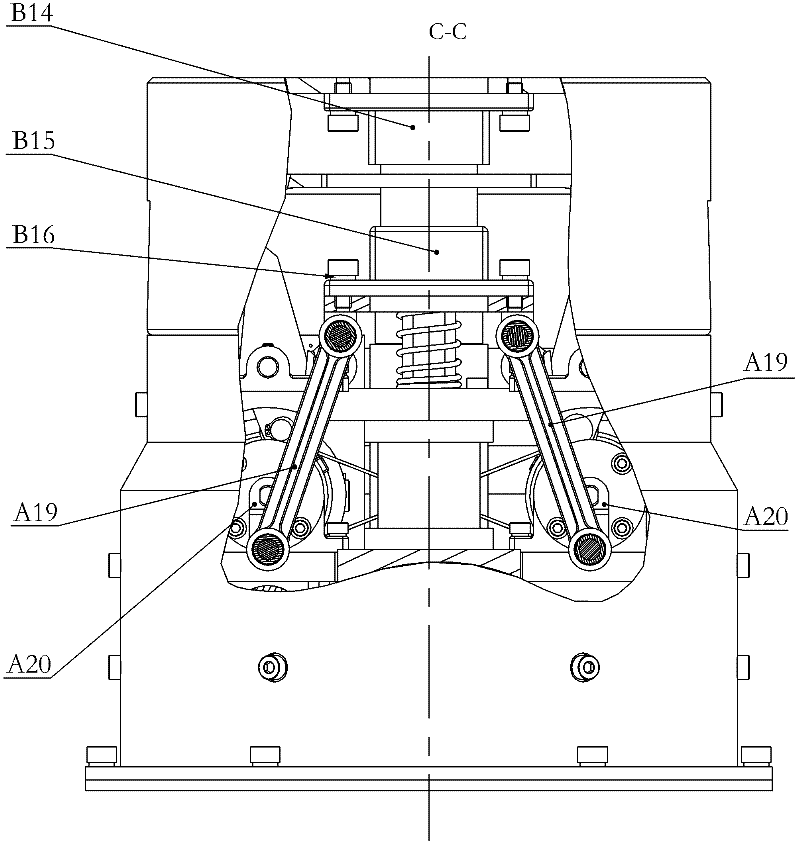

[0020] Specific implementation mode one: as Figure 1-8 As shown, the space robot rail tool changer described in this embodiment includes a housing A2, a bottom end cover A8, a lower support ring A9, an upper support ring A12, a circuit board support frame A16, an electrical system, a first drive system and The second set of drive system, the upper support ring A12, the fixing frame A37, the lower support ring A9, and the circuit board support frame A16 are installed in the housing A2 from top to bottom, the electrical system, the first set of drive system and the second set of drive system The system is placed in the housing A2, the electrical system is placed on the circuit board support frame A16, and the lower end surface of the housing A2 is connected to the bottom end cover A8 (through the screw B30);

[0021] The first drive system includes a first input device, a first transmission device and a first output device, the first input device is the first motor B13 with a p...

specific Embodiment approach 2

[0026] Specific implementation mode two: as Figure 1-8 As shown, the pushing stroke of the locking finger A5 in this embodiment can press the tool end interface A1; in the remote stroke of the locking finger A5, the cam A6 can idle to realize the docking of the electrical connector interface. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0027] Specific implementation mode three: as Figure 1-8 As shown, the limit switch of the second drive system described in this embodiment adopts Hall sensor B35, and Hall sensor B35 is glued to the support block A23 above the bearing seat A24 by glue, and the magnet steel B36 is embedded in the cam length. On the side of the shaft gear A21, the second drive system uses the potentiometer B40 for absolute position sensing, and the potentiometer B40 is soldered on the PCB. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com