Productive technique for multicolor granite aluminum composite panel

A production process and technology of aluminum-plastic panels, applied in the field of building decoration materials, can solve the problems of poor waterproof and corrosion resistance, heavy weight, poor adhesion between the simulation layer and aluminum-plastic panels, etc., to achieve strong waterproof and corrosion resistance, Increase the bonding adhesion and alleviate the effect of resource shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

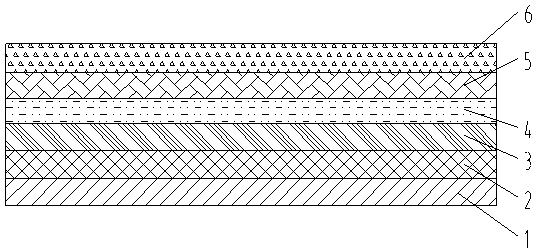

[0024] see figure 1 , the present invention relates to a multi-color paint granite aluminum-plastic plate, which includes a base material layer 1 of the aluminum-plastic plate, a smooth putty layer 2 is arranged on the upper surface of the base material layer 1, and an interface is arranged on the surface of the smooth putty layer 2 agent layer 3, the surface of the interface agent layer 3 is provided with a primer layer 4, the surface of the primer layer 4 is provided with a main material paint layer 5, and the surface of the main material paint layer 5 is provided with a topcoat layer 6, which specifically The process steps are as follows:

[0025] Step 1. Take an aluminum-plastic panel, clean and polish it to form the base layer of the aluminum-plastic panel;

[0026] Step 2: Spray a layer of ternary chlorine-vinegar copolymer resin on the base surface of the aluminum-plastic board, place it in a ventilated place to dry naturally for 1~2H, and then dry for 1~2H at a drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com