Low-temperature energy saving generation system

An energy-saving power generation and low-temperature technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems that affect the ecological environment and life safety, high electricity price costs, and difficult construction, etc., to achieve improved cycle power generation efficiency, simple structure, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

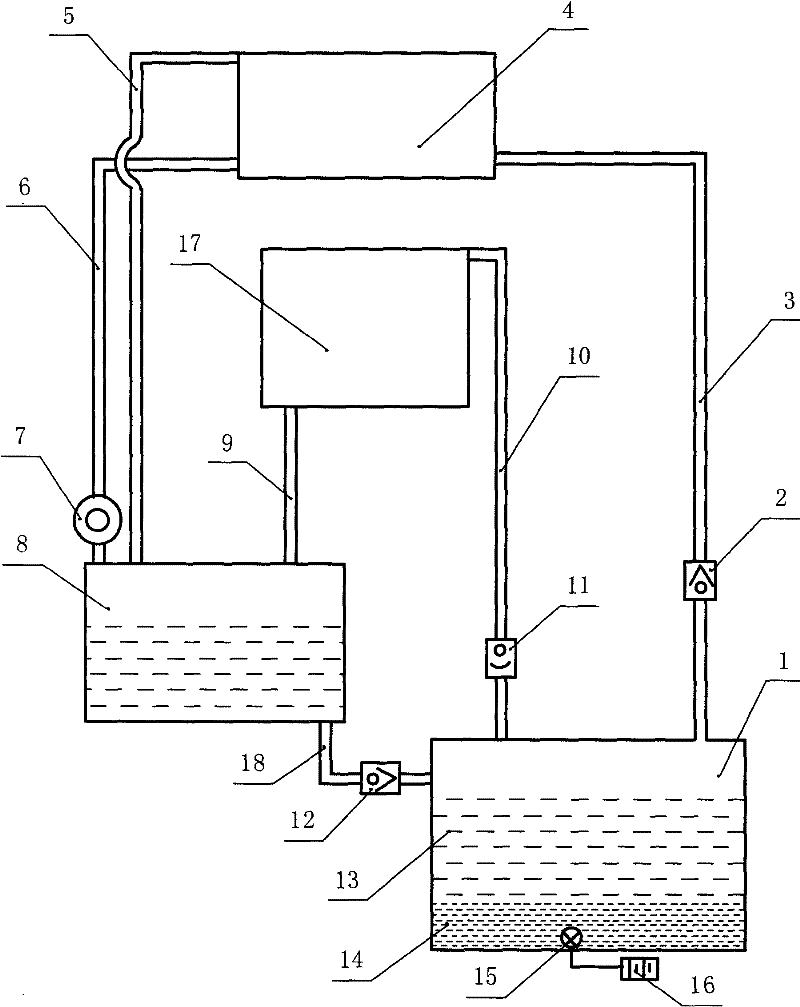

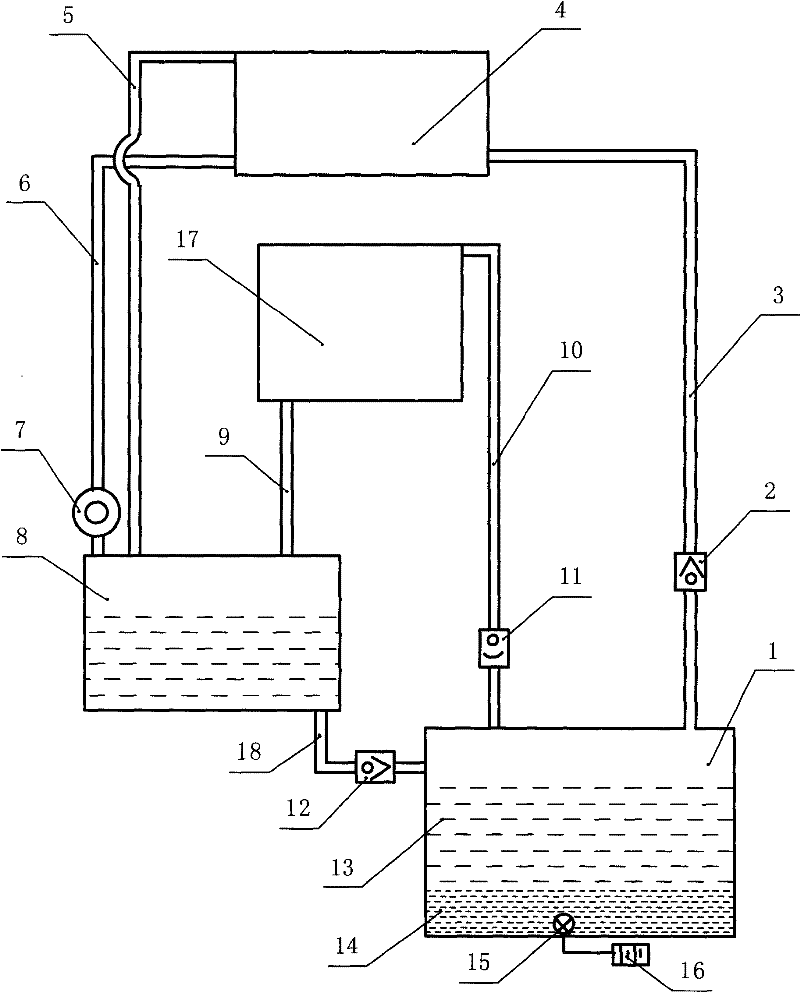

[0014] Below in conjunction with accompanying drawing, the present invention will be further described:

[0015] see figure 1 , the names of the components represented by the serial numbers in the figure are: 1-energy chamber, 2-one-way flow valve, 3-upper water pipe, 4-high level chamber, 5-air guide pipe, 6-down water pipe, 7-hydraulic generator, 8-water source warehouse, 9-cooling pipe, 10-exhaust pipe, 11-one-way exhaust valve, 12-one-way flow valve, 13-water, 14-low boiling point high-density liquid, 15-heater, 16- External temperature control switch, 17-cooling chamber, 18-communicating pipe.

[0016] A low-temperature energy-saving power generation system, comprising an energy bin 1, a high-level bin 4, a water turbine generator 7, and a water source bin 8. The energy bin 1 communicates with the high-level bin 4 through an upper water pipe 3, and the upper water pipe 3 is provided with a single to the circulation valve 2; the high position chamber 4 communicates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com