Load-bearing anti-freezing solar thermal collector tube

A solar collector tube and pressure-bearing technology, which is applied in the field of solar collector tubes, can solve the problems of all-glass vacuum collector tubes, such as exploding tubes and running water, and achieves the effects of easy on-site installation, safe use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

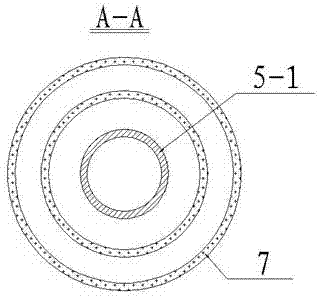

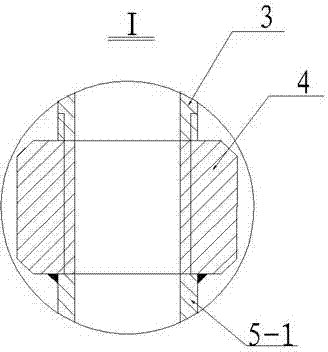

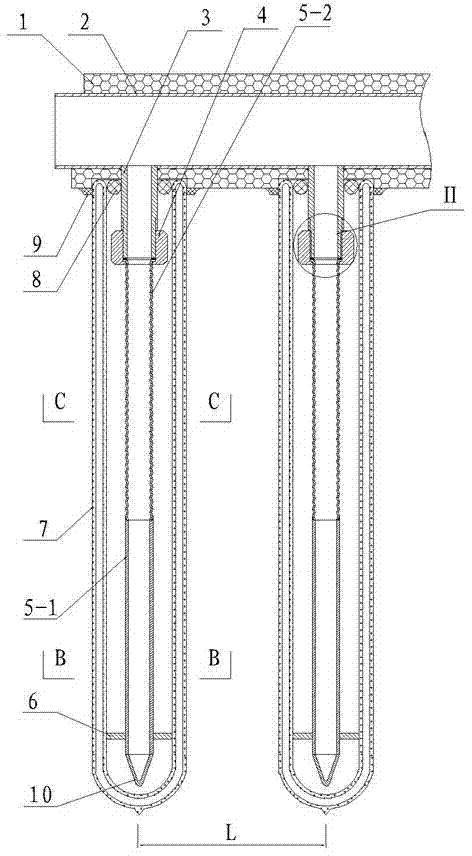

[0029] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the present invention includes an all-glass vacuum heat-collecting tube 7, and a metal heat-exchanging tube 5-1 with a length of 1400 mm to 1700 mm and a diameter of 15 mm to 25 mm is inserted in the middle of the all-glass vacuum heat-collecting tube 7 with an inner diameter of 47 mm, and a circlip 6 Fixing, the bottom end of the metal heat exchange tube 5-1 is welded to the antifreeze conical tube 10 for sealing, the quick connection nut 4 is welded at the top opening of the metal heat exchange tube 5-1, and the quick connection nut 4 is threaded with the The connecting pipe 3 of the collecting water tank connected to the collecting water tank; during use, the metal heat exchange tube 5-1 of the present invention is threadedly connected with the collecting water tank 2 through the connecting pipe 3 of the collecting water tank (if the collecting water tank 2 Unprocessed thread, the connection pipe 3 o...

specific Embodiment approach 2

[0031] Such as Figure 4 ~ Figure 7 As shown, the present invention includes an all-glass vacuum heat collecting tube 7, and inserts a metal heat exchange tube 5-1 with a length of 100 mm to 1300 mm and a diameter of 15 mm to 25 mm in the middle of the all glass vacuum heat collecting tube 7 with an inner diameter of 47 mm, and a metal heat exchange tube 5-1 with a circlip 6 Fixed, the bottom end of the metal heat exchange tube 5-1 is welded with an antifreeze conical tube 10 for sealing, and the upper end of the metal heat exchange tube 5-1 is welded with a length of 100 mm to 1600 mm, and the engineering diameter is the same as that of the metal heat exchange tube (5-1 1) Equal heat exchange bellows 5-2 (shorten the length of the metal heat exchange tube 5-1 accordingly to ensure that the length of the heat exchange tube is 1400mm ~ 1700mm), and set the quick connection nut 4 outside the heat exchange bellows 5-2, The top of the heat exchange corrugated pipe 5-2 is processed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com