Laminated sheet type ceramic delay line

A delay line and layered technology, applied in the direction of delay lines, electrical components, circuits, etc., can solve the problems of unfavorable system miniaturization, unsuitable communication products, large delay lines, etc., and achieve high reliability and high quality factor , The effect of widening the working frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

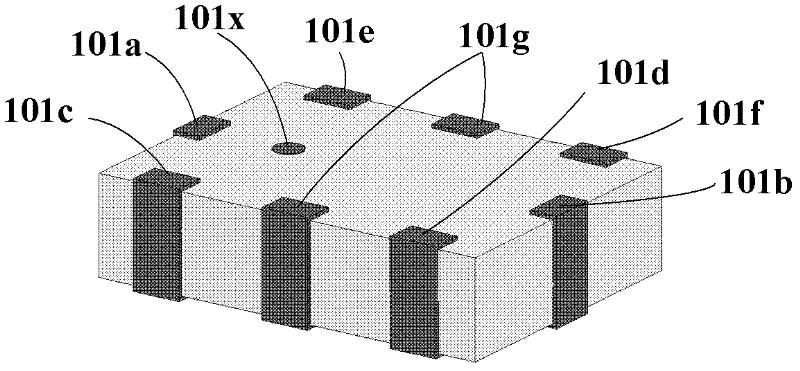

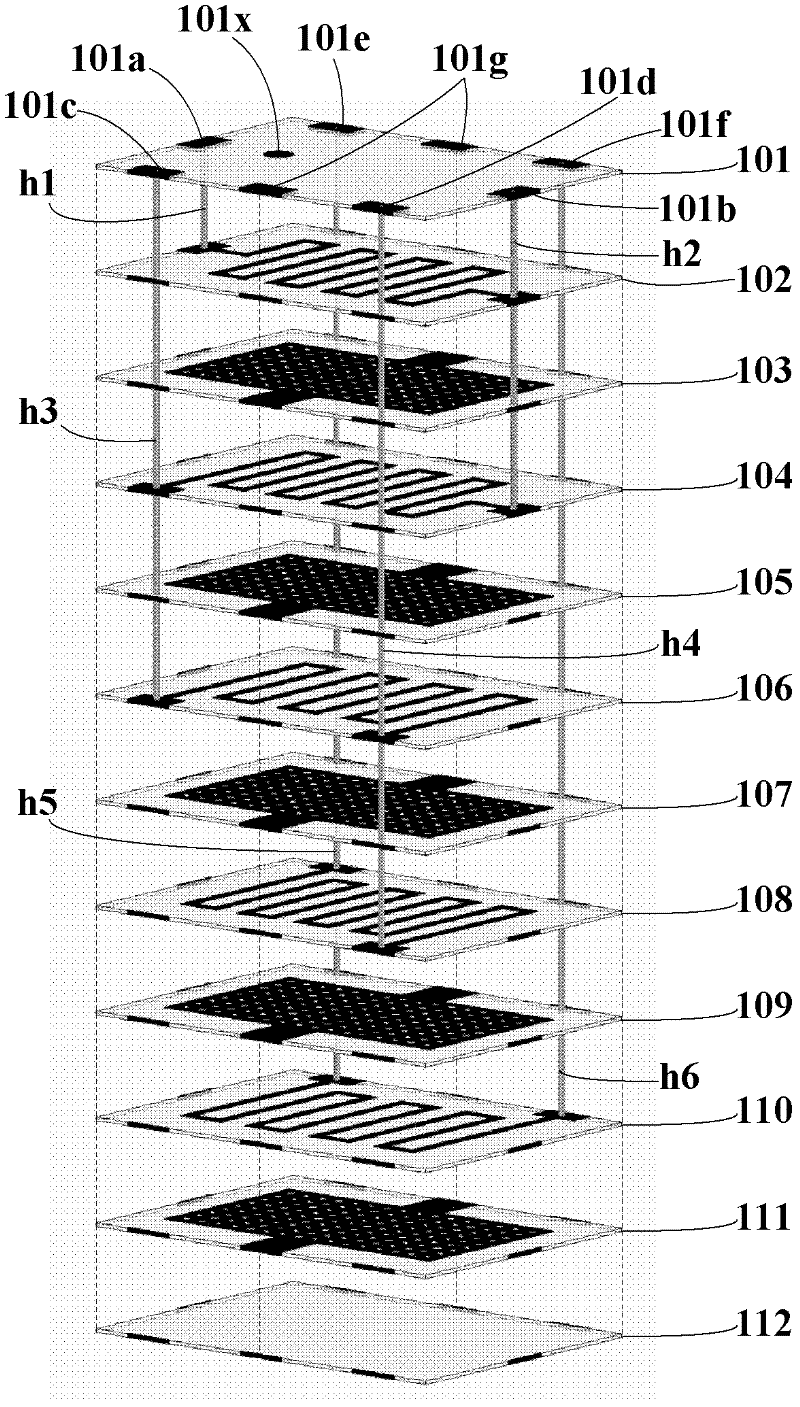

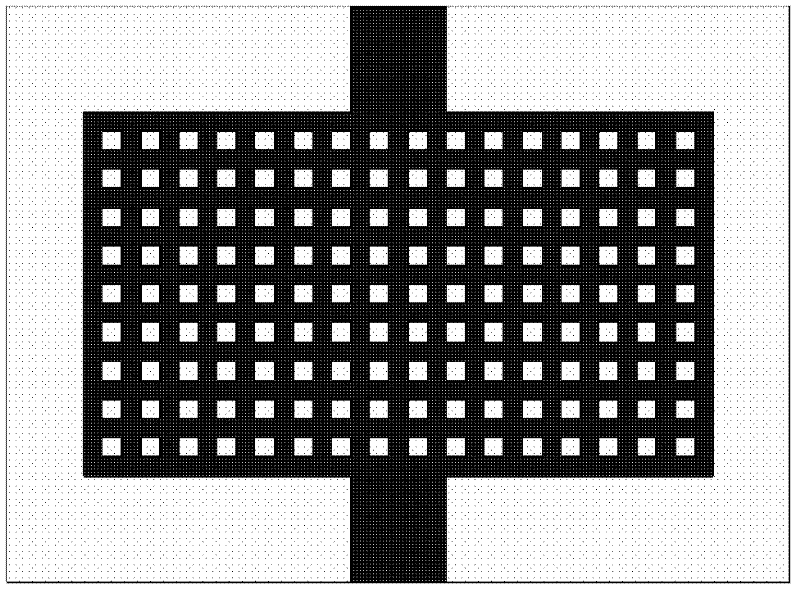

[0025] Such as figure 1 , 2 , 3, the laminated chip ceramic delay line includes 12 layers of chip ceramic media 101, 102, 103, 104, 105, 106, 107, 108, 109, 110, 111, 112; the folded metal Conductive metal is used to print the conductive metal on the top of the sheet-shaped ceramic dielectric layers 102, 104, 106, 108, 110; the grid-like metal layer is printed on the top of the sheet-shaped ceramic dielectric layers 103, 105, 107, 109, 111 with conductive metal; The metallized through hole h1 connects the device signal input end 101a and the input end of the first metal line delay unit, and the metallized through hole h2 connects the first signal output end 101b, the output end of the first metal line delay unit and the second metal line delay unit The input end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com