Feeding device of reinforcing particles of metallic matrix composite material cast by vacuum mixing

A technology of vacuum stirring and casting metal, which is applied in the field of feeding devices for vacuum stirring and casting particle-reinforced metal matrix composites, which can solve the problems of deformation of the pretreatment furnace, affecting the vacuum sealing of the device, and difficulty in ensuring the quality stability of composite materials, etc. Evaporation and avoid accumulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

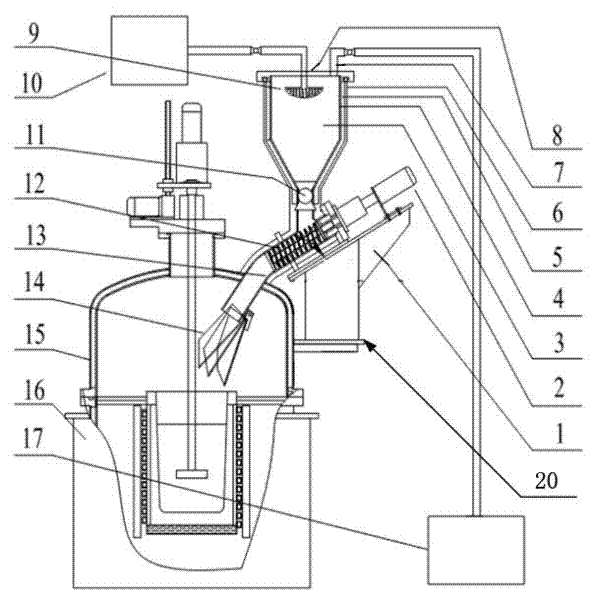

[0020] like figure 1 As shown, a reinforcing particle adding device for vacuum stirring casting metal matrix composites includes a vacuum stirring melting furnace 16 and a hopper 3, a vacuum stirring melting furnace cover 15 is installed on the upper end of the vacuum stirring melting furnace 6, and a vacuum stirring melting furnace cover 15 A particle conveying device 20 is installed through the bracket 1 on the upper side of the upper side. The particle conveying device 20 is arranged obliquely. The inclination angle of the particle conveying device 20 can be at any position within 0o to 90o. The bottom of the hopper 3 is connected. The hopper 3 is composed of a smooth metal or ceramic lining 4, an insulation layer 5 and a metal shell 6. A vacuum valve 11 is provided on the bottom port of the hopper 3, and a hopper cover 8 is installed on the top of the hopper 3. , the hopper cover 8 is connected with a vacuum bypass interface 7, the vacuum bypass interface 7 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com